It is funny how life works its way into things. Work, family, spouse, friends... Pretty soon, the days turn to weeks; the weeks to months; the months to years. A lot has transpired since then, but it hasn't involved much in the way of working with the machinery. Nonetheless, life has been good for us, so no complaints.

Well, after reading

this topic here on HMEM, I have been inspired to jump back on the Crusader project and see about wrapping it up. When I started this project over 2 years ago, I had started taking the HMEM community along with me. So, here we are a bit over two years later...

Resurrecting a "dinosaur" thread!

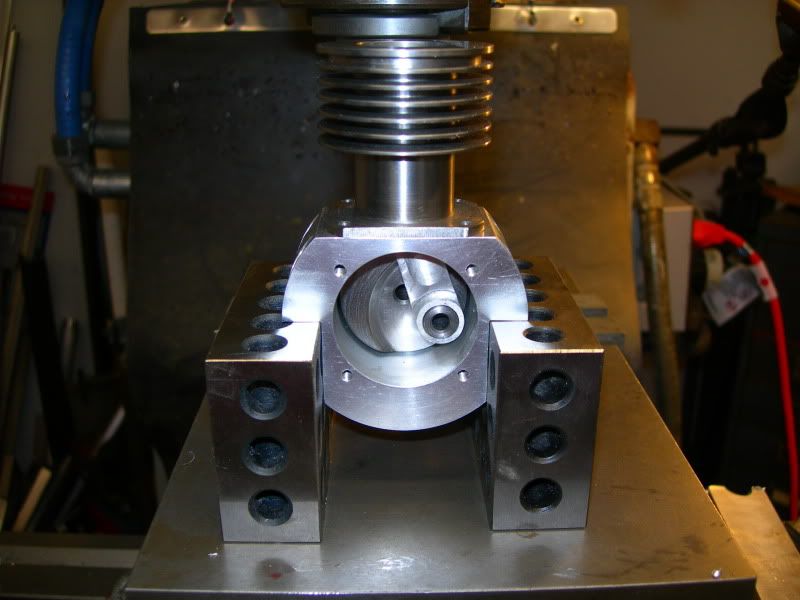

Okay, so back to it. This evening was spent going over the pieces that have been made, checking measurements, reviewing the plans and getting a feel of where I left off. The remaining items are the piston, connecting rod, valve and bushing, exhaust manifold, bypass cover, carb assembly (which may go commercial), hub, spinner, and some misc. hardware items.

Existing parts that have machining (beyond drilling/tapping) left are the head, rear engine plate, and cylinder.

When I had to set the project aside, I took the time to put a light coat of oil on the pieces and store them in plastic bags. A quick cleaning and we are where we left off without the issues of corrosion and dust.

There are a few things I need to gather up in the way of bar stock, so a trip to the local metal supplier is in store. I'll get by this week and gather up some materials, and hopefully have some pictures with fresh chips to share in a few days.

'til then,

An excited and reinvigorated Wareagle!