Hi Guys,

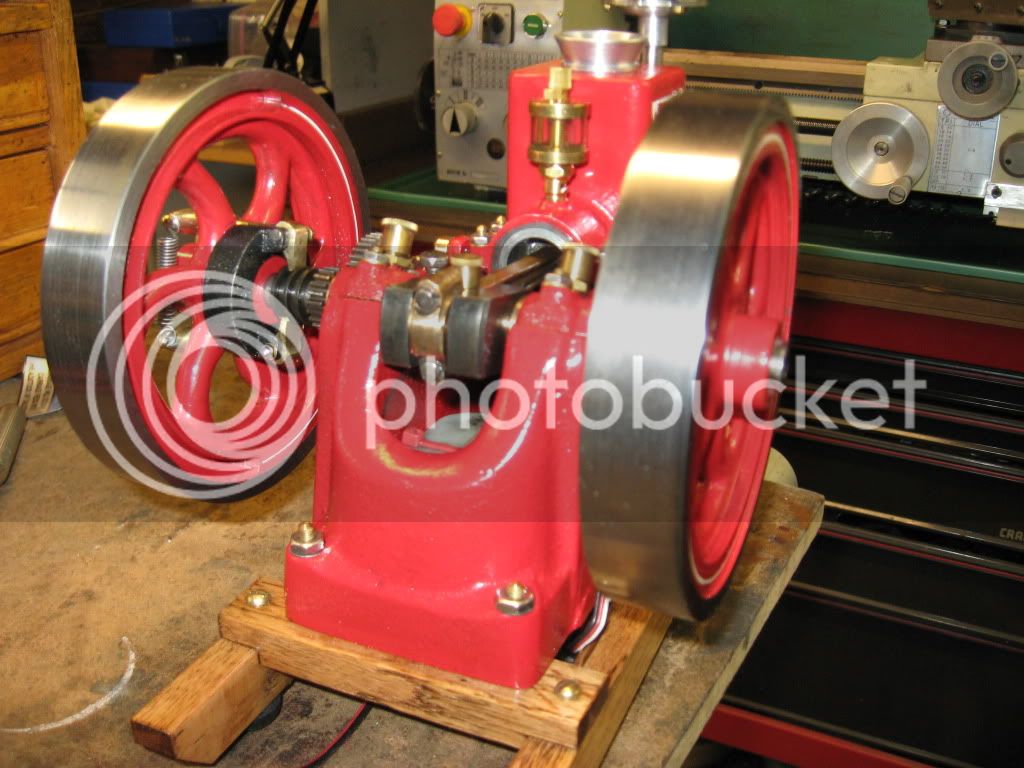

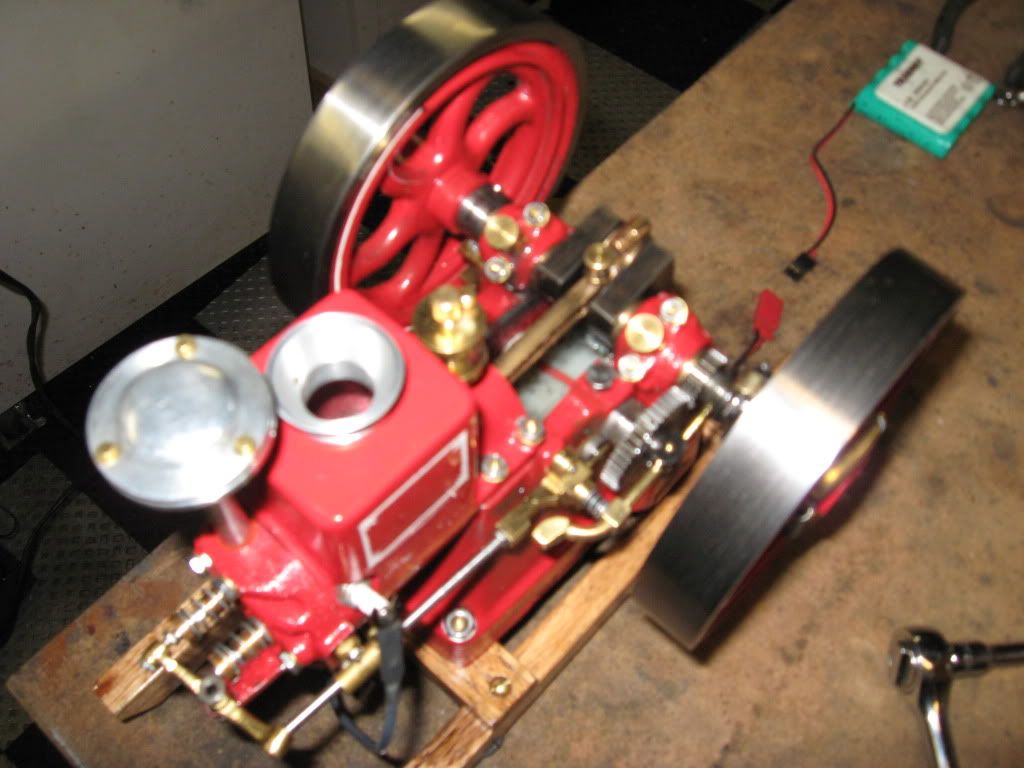

Well I did the other side with pinstripe. No sense boring you with that pic......looks just like the other side.

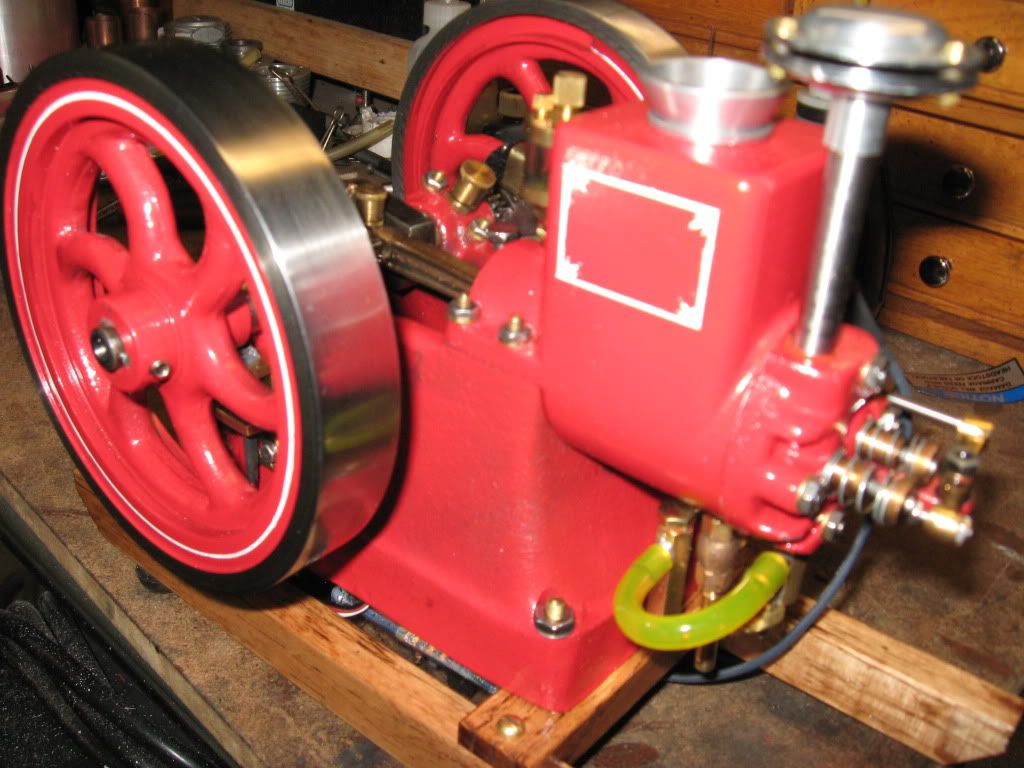

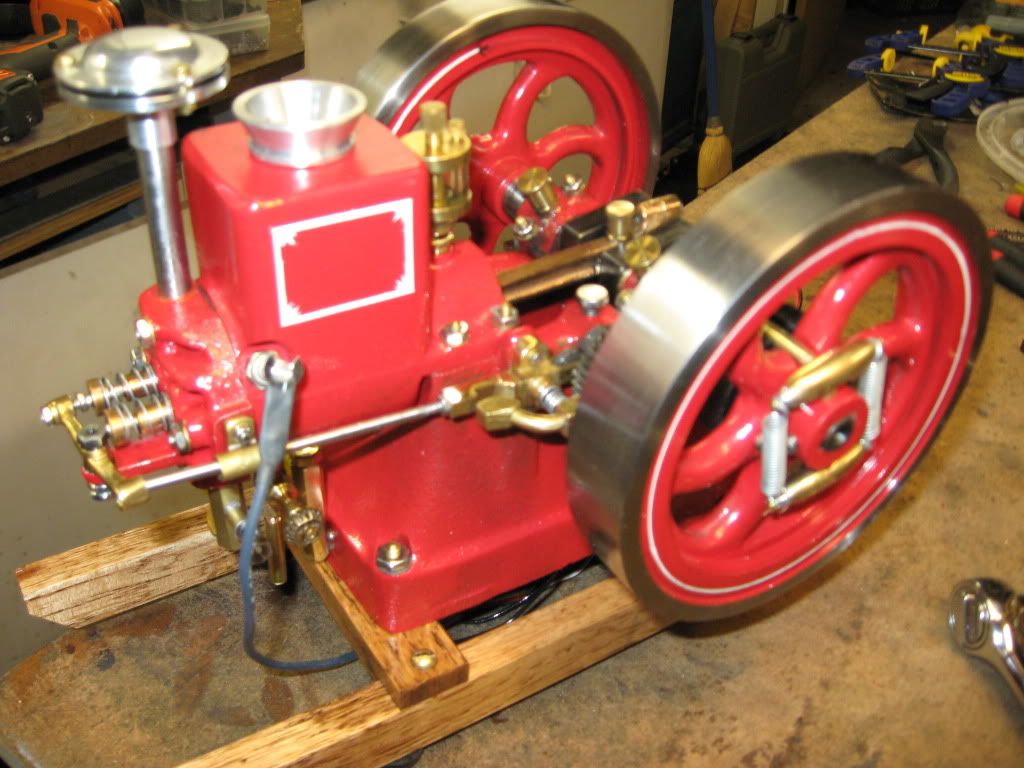

But I do have a question. I've seen on some engines (don't remember who's) a placard. Looks like black backround with brass border and lettering. Similar to what the full size mfg would have put on their engine with serial #, Date of mfg, logo.......

Is this another trophy place type item? Or?

Tony

http://hamiltonupshur.tripod.com

Well I did the other side with pinstripe. No sense boring you with that pic......looks just like the other side.

But I do have a question. I've seen on some engines (don't remember who's) a placard. Looks like black backround with brass border and lettering. Similar to what the full size mfg would have put on their engine with serial #, Date of mfg, logo.......

Is this another trophy place type item? Or?

Tony

http://hamiltonupshur.tripod.com