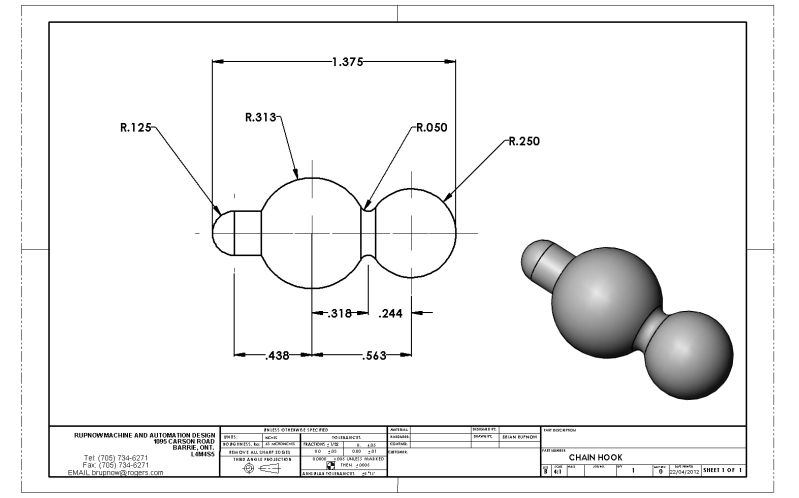

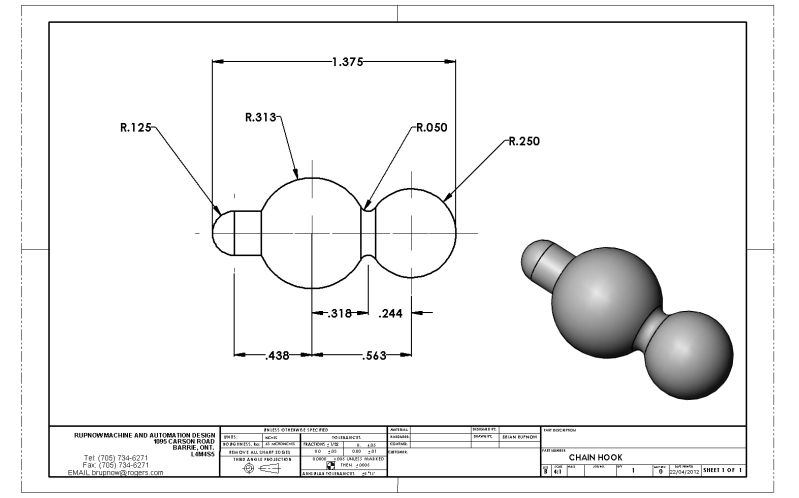

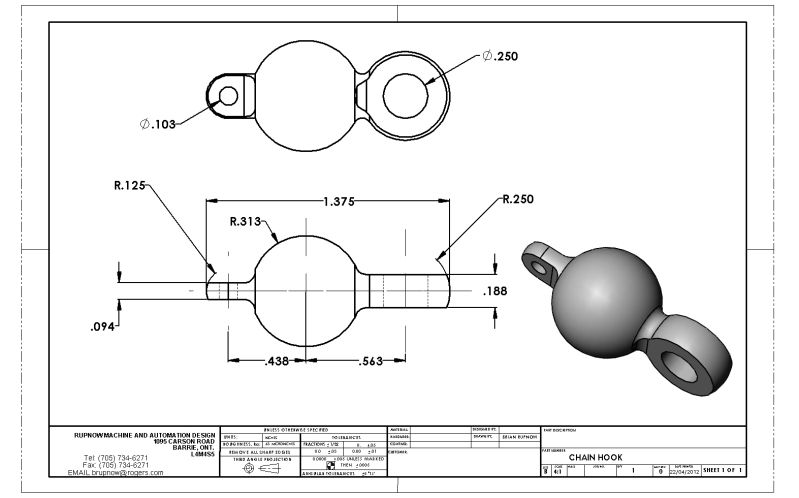

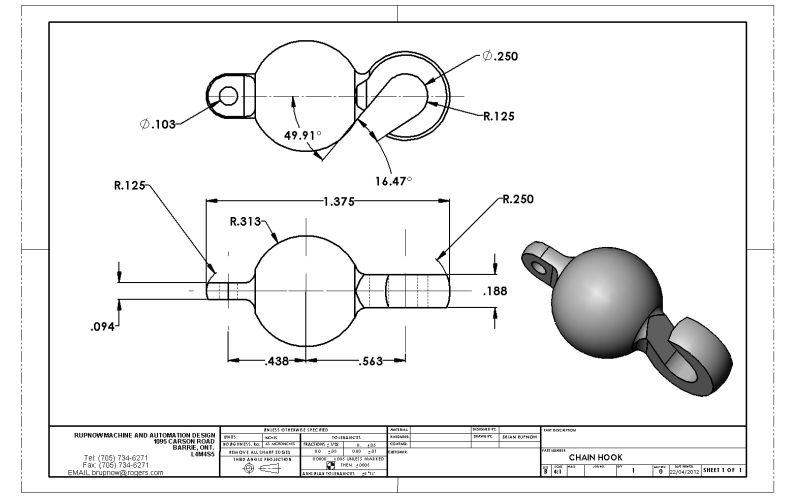

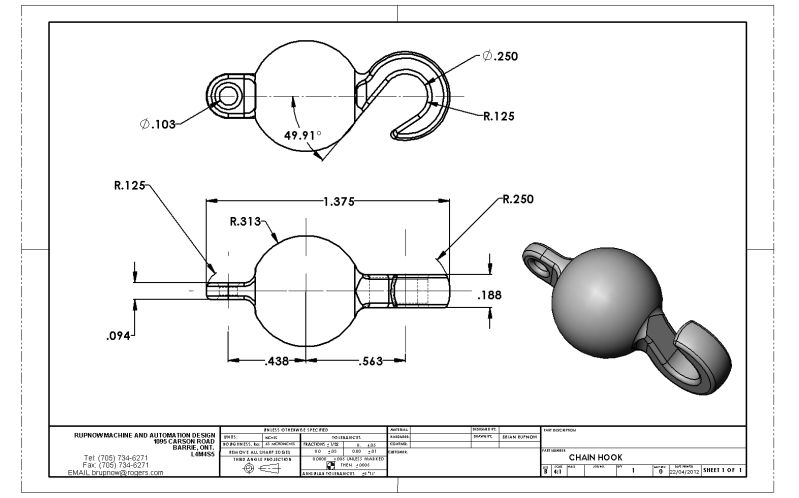

I need a chain hook for the end of the winch cable on my donkey engine. This morning I'm setting in my office, goofing around with ideas. I'm just thinking that if I chucked up a piece of 5/8" steel rod in my lathe, I could probably use a cutting tool and some file work to achieve this without too much trouble.