Hello People!

I`m new here and on the HMEM.

After some research on the web I found some very nice projects (V8 from Steve Huck, Tiny Inline 4 from Kelly, The Peewee from Dirk, Jerry Howell V4, 4 Cyl. Horz. Opposed from Dale Detrich and another V8 from Coles Power Models).

I decided too buy all them. After some study I decided as my first IC Engine building project the TINY INLINE 4. First I though it would be easier but the parts are so small that is being a real challenge. "I will not give up."

Bollow is the first pictures:

Sorry for the English writing mistakes.

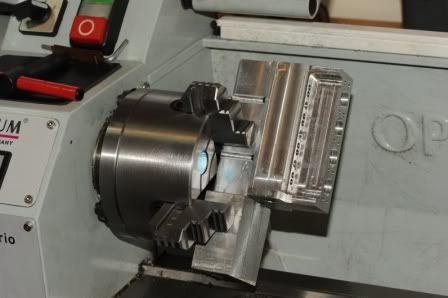

Part of Raw Material

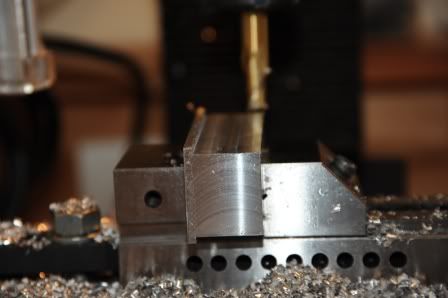

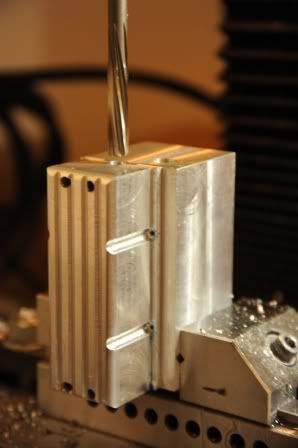

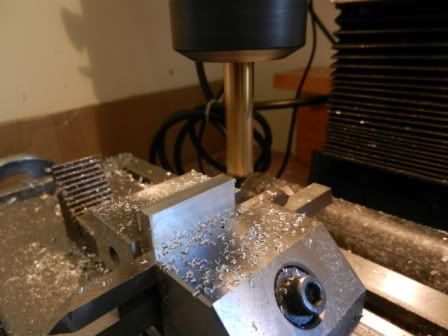

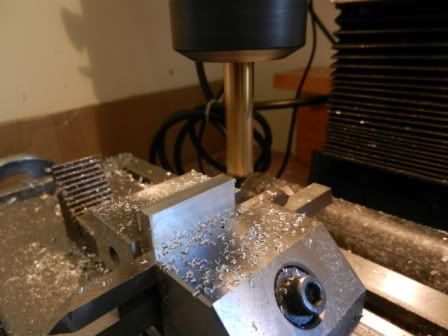

Preparing the stock for the block

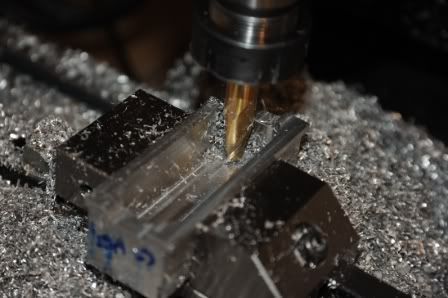

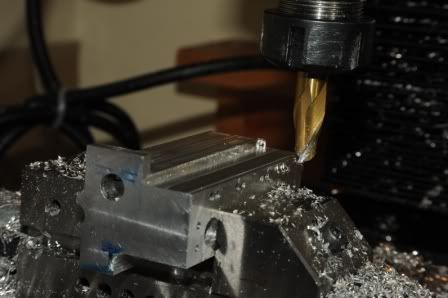

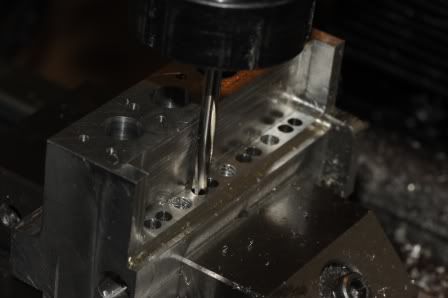

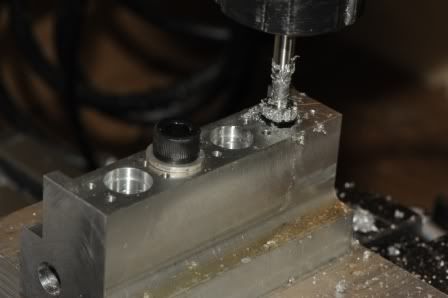

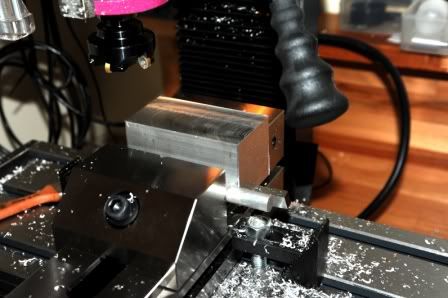

Start of botton machining

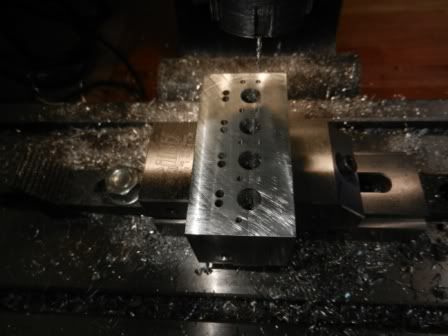

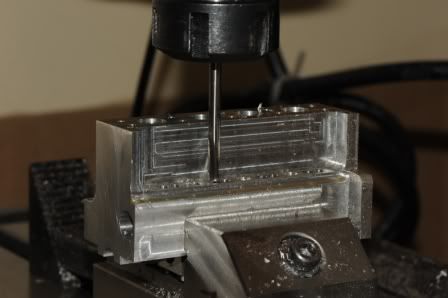

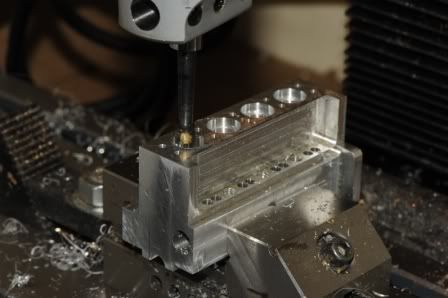

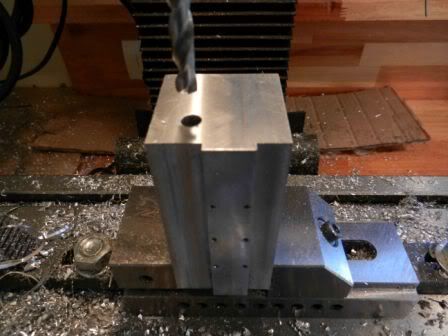

Drilling the Camshaft Tunel

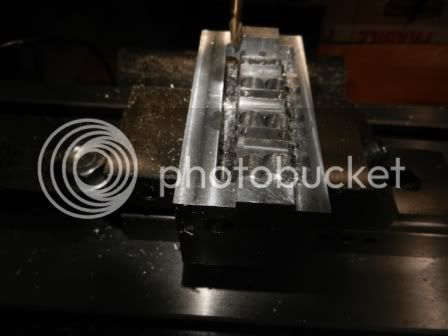

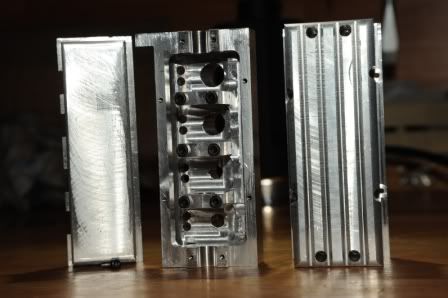

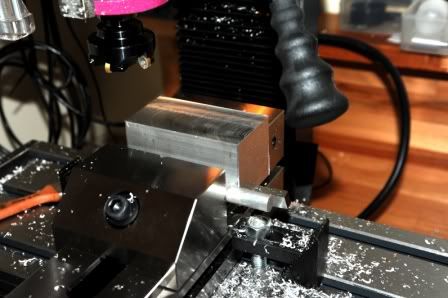

The Center Main Bearings Caps. I machined the material to its lenght than I sectioned using Hand saw.

Machining the caps to its thickness

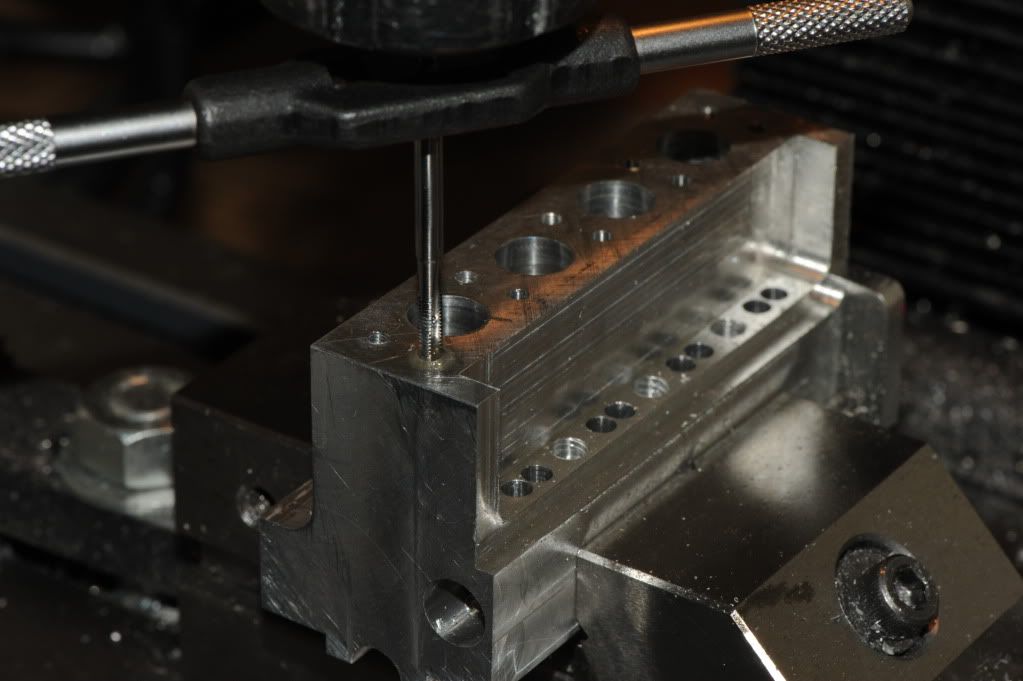

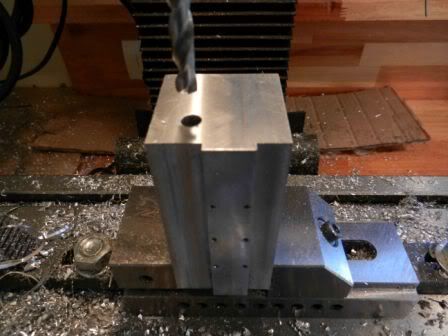

Drilling the screw holes on the caps

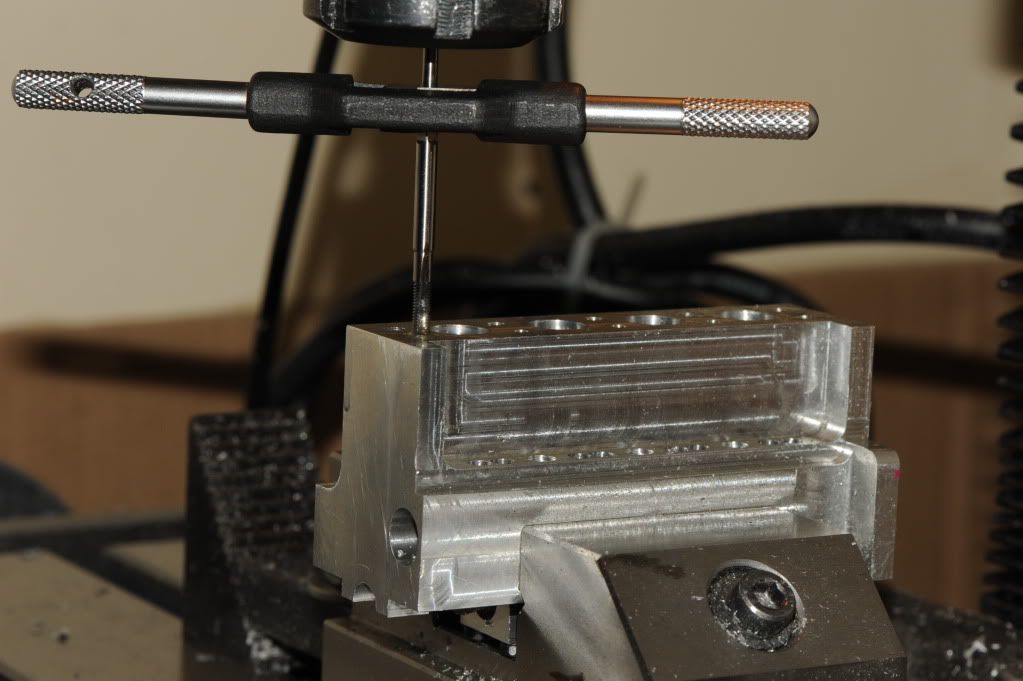

Ready for starting digging the botton

MORE PHOTOS IS COMMING. See you soon guys.

I`m new here and on the HMEM.

After some research on the web I found some very nice projects (V8 from Steve Huck, Tiny Inline 4 from Kelly, The Peewee from Dirk, Jerry Howell V4, 4 Cyl. Horz. Opposed from Dale Detrich and another V8 from Coles Power Models).

I decided too buy all them. After some study I decided as my first IC Engine building project the TINY INLINE 4. First I though it would be easier but the parts are so small that is being a real challenge. "I will not give up."

Bollow is the first pictures:

Sorry for the English writing mistakes.

Part of Raw Material

Preparing the stock for the block

Start of botton machining

Drilling the Camshaft Tunel

The Center Main Bearings Caps. I machined the material to its lenght than I sectioned using Hand saw.

Machining the caps to its thickness

Drilling the screw holes on the caps

Ready for starting digging the botton

MORE PHOTOS IS COMMING. See you soon guys.