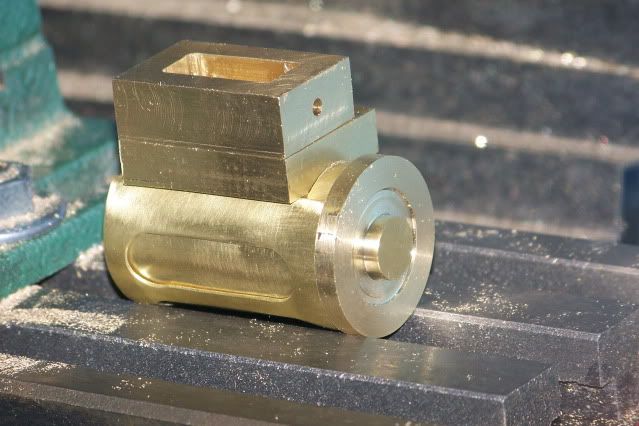

Today I got to work on the cylinders. This is what I am aiming for:

The cylinders hang outside the frame. They are mounted by bolting the valve steam chest to the deck. The packing gland is not the normal threaded nut. The adjustable part (normally the nut) is a clamp adjusted by nuts on studs 180 deg apart.

There is an extended neck on the cylinder head that supports a bracket that in turn supports one end of the cross head.

The most eye catching feature is the fluted lagging on the cylinder body. This has been a nagging concern since I started this project. I thought for a while that I would just ignore this little detail. There's no way I can do that, so I'll just make the cylinders plain and try to do something with paint. Then Cedge started show impossible stuff on his tandem engine build and that plan went out the window. Nothing replaced it. I still didn't know what I was going to do.

I was working on a valve plate and clamped down on the vise a little two hard and it bowed up in the middle. AHA!

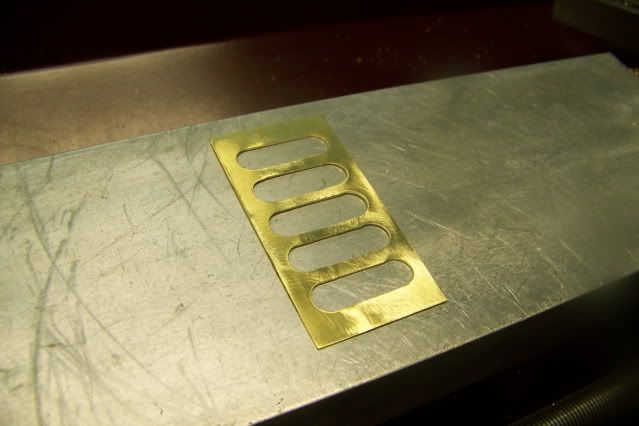

A little layout, a little drilling and milling:

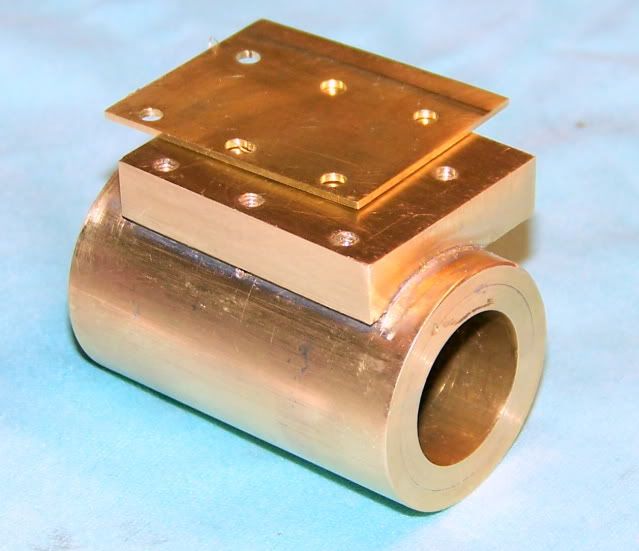

A little clamping and bending:

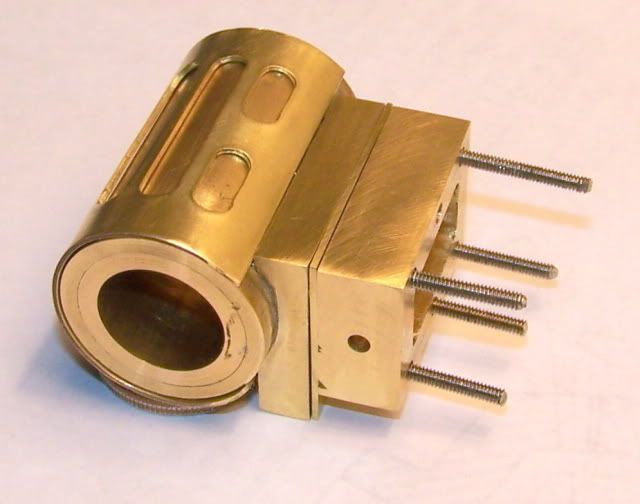

And I'm almost there. The problem is that with the cutouts the plate doesn't bend evenly. I tried lots of things but what finally worked was to turn a mandrel about 1/8th inch less than the cylinder body and bend the plate around that and then drive the assembly into a piece of PVC Pipe fitting. The next picture shows the plate inside the pipe and as you can see, it is not perfect, still has lots of sharp bends and flats.

But, the PVC provides protection and form and the little hammer provides the persuasion and before long the plate is looking so good I forgot to take another picture in the fixture.

This is where I was when the thunderstorm hit and tree limbs and branches were bouncing off the shed so I grabbed the camera, called the dog, and headed for the barn.

It ended quickly with no real damage, but by that time It was beer and dogie play time so we called it quits for today. More tomorrow.

Jerry