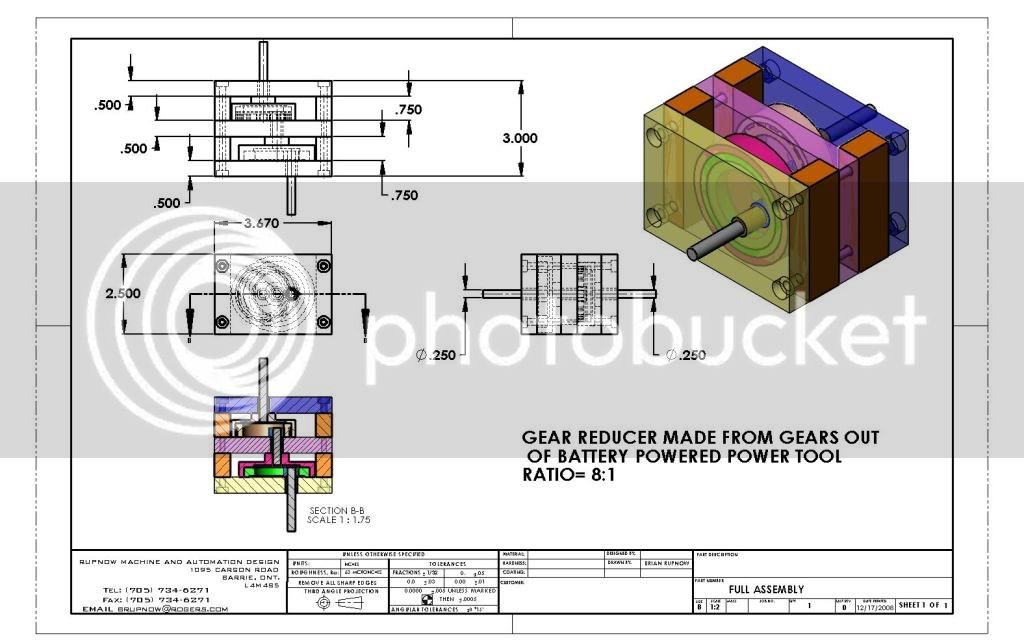

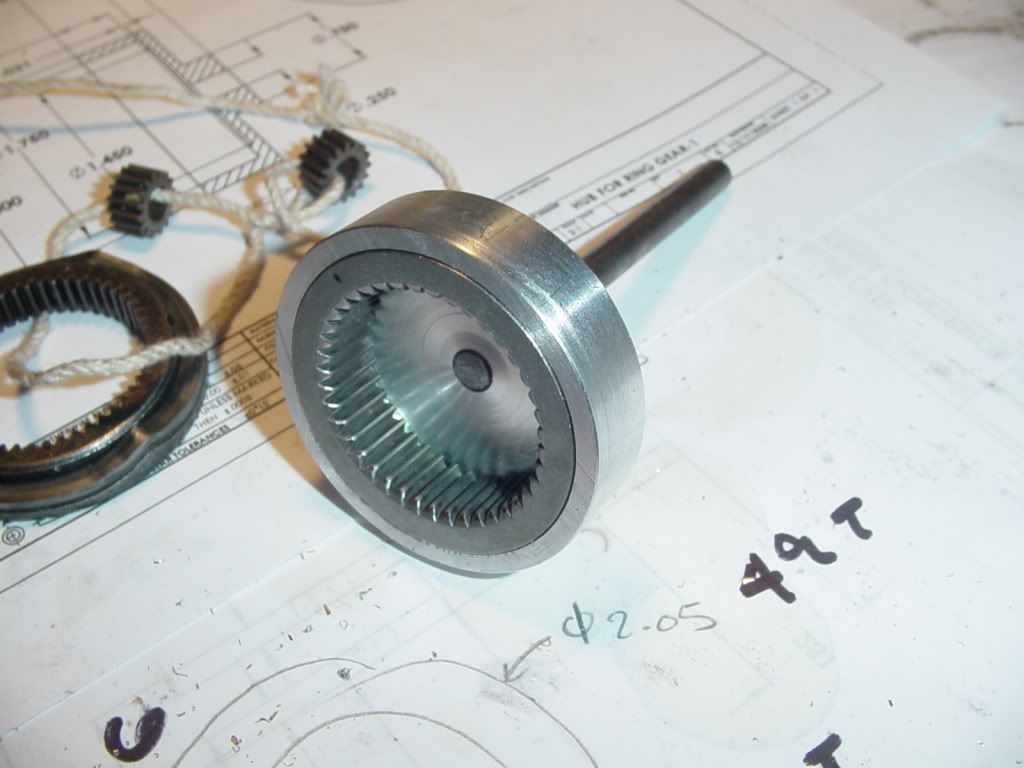

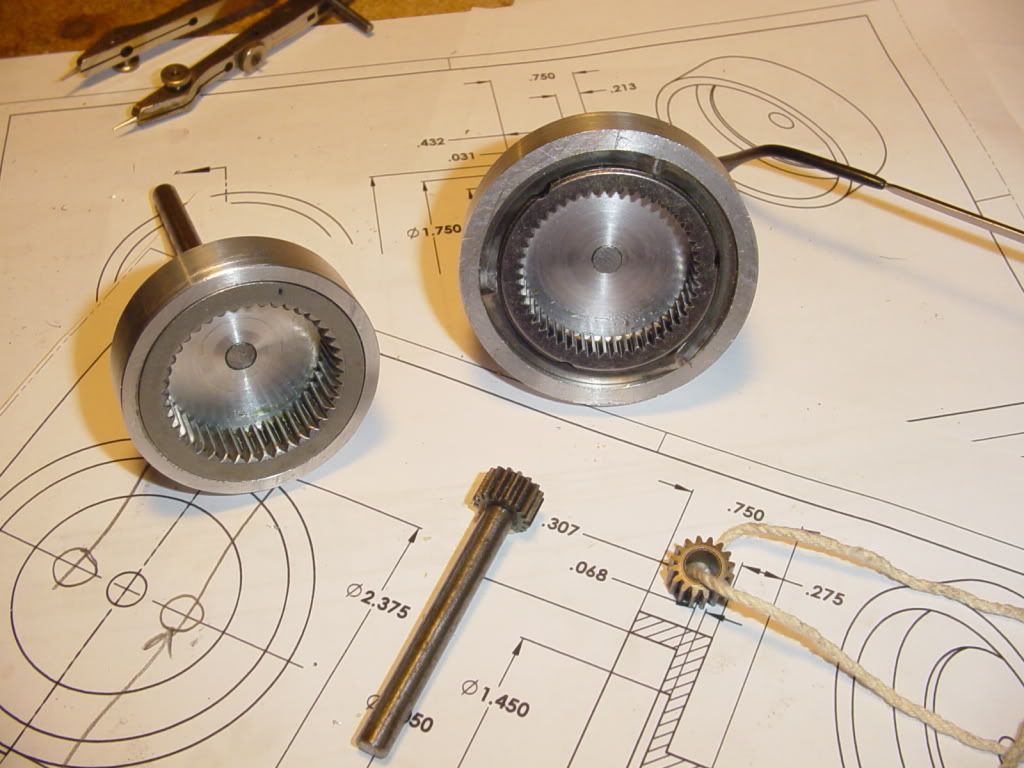

Why???---Just because I can!!! Now that I have a lifetime supply of little gears---FREE little gears---Stay tuned.

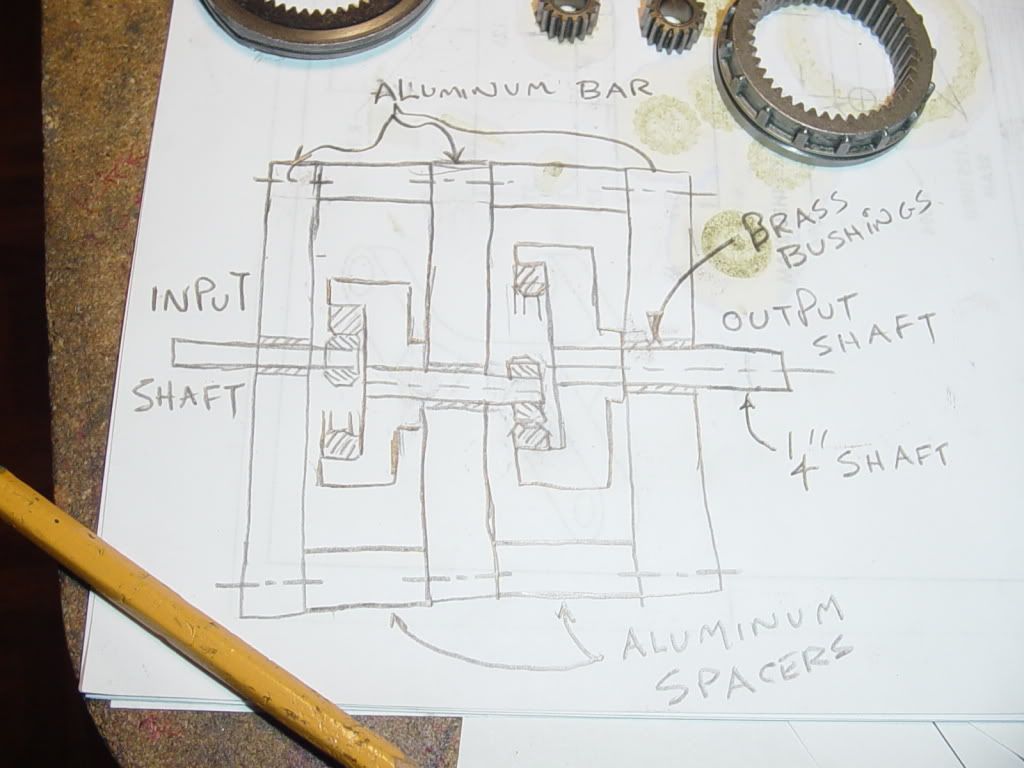

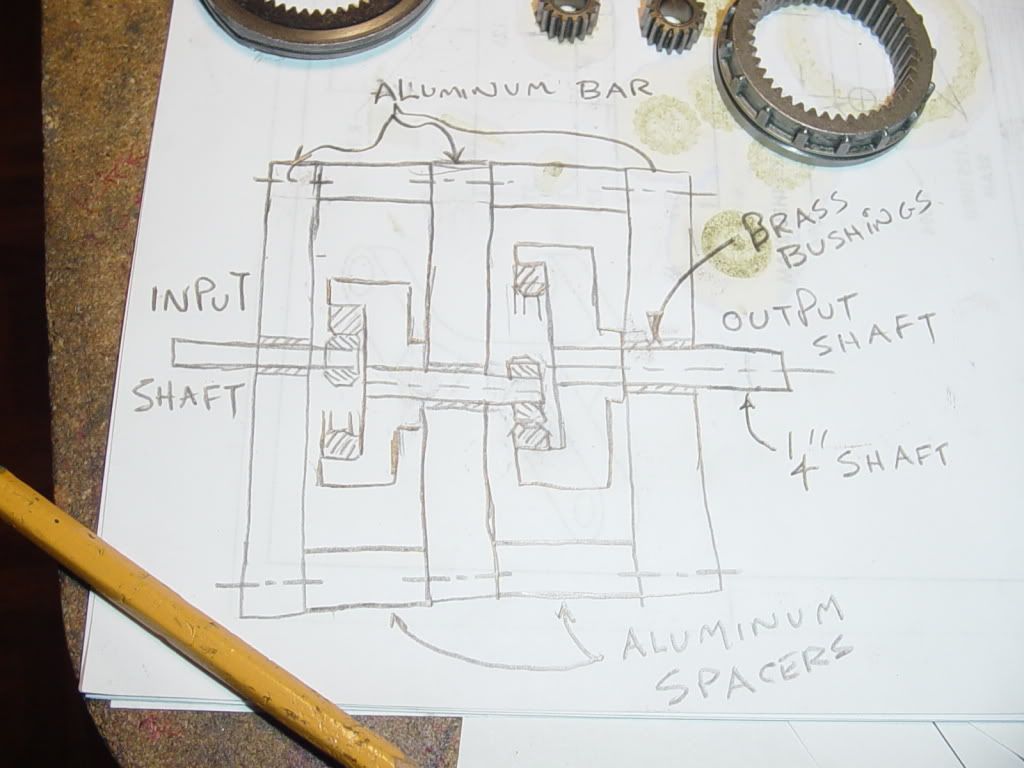

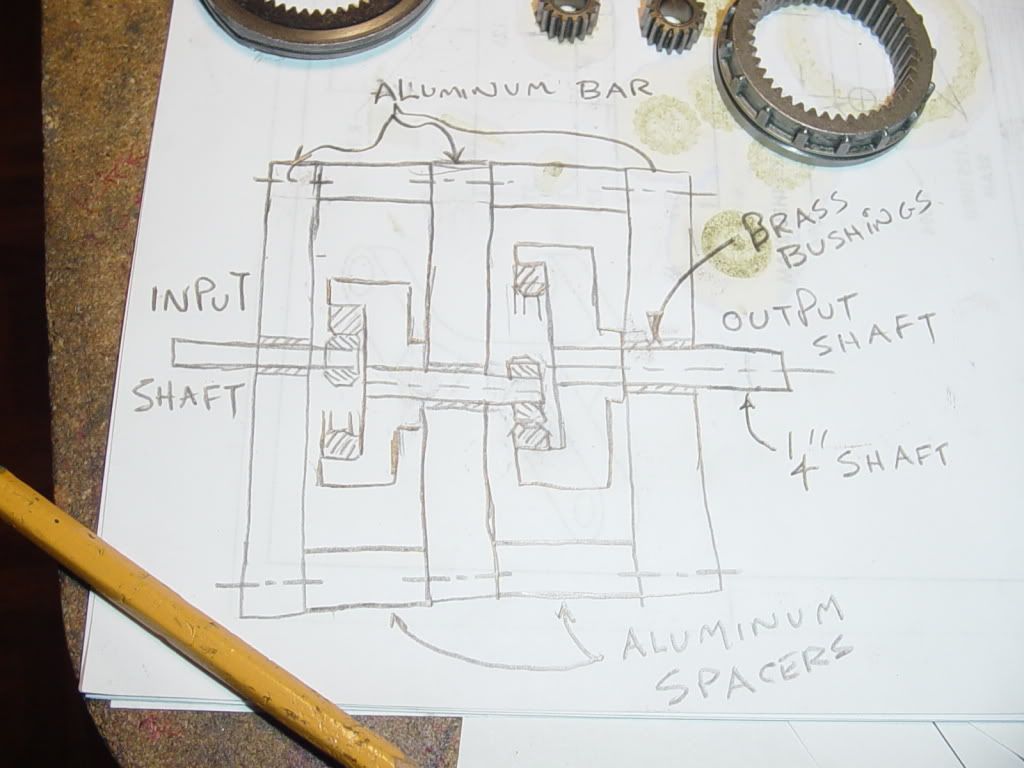

Yeah, your right. I have reduced the plate thickness to 1/2". No ball bearings though. I have aluminum and brass, and this is not going to be a high speed unit anyways.rleete said:3/4"? Planning to drive a tractor with it? Find some miniature ball bearings (printers are a great source), and cut those plates down to 1/4"

BrianS said:Hi,

Nice gearbox ya got there. What ratio would you have gotten if you just left the planetary arrangement together? I mean like you drove the sun gear and the output shaft was off the planets or spider with the ring gear locked? I need to make a visit to my local tool repair place. I hope they are as nice as the one near you.

Enter your email address to join: