I missed out a few photos of the next stages but this is what I have.

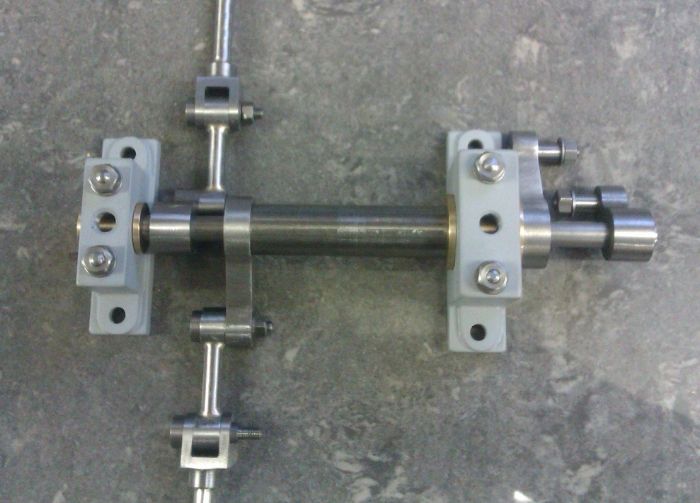

The parts for the regulator valve prior to soldering.

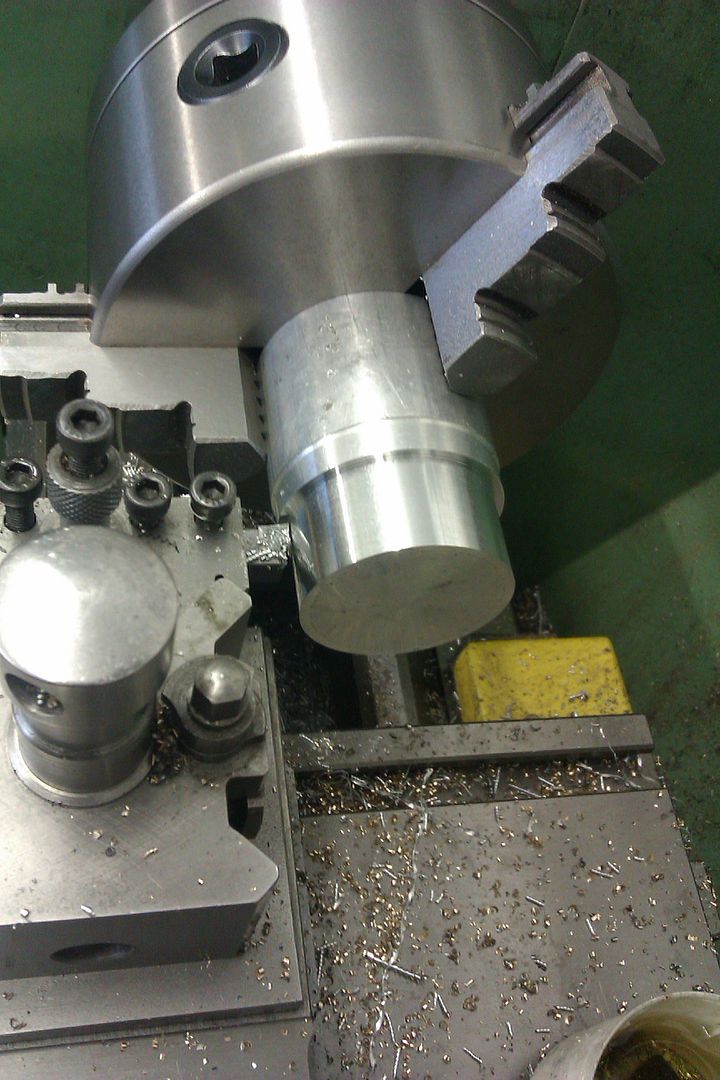

The profile of the valve handwheel was machined on the lathe before transfering to the R/t to first cut the spokes

And then remove the waste

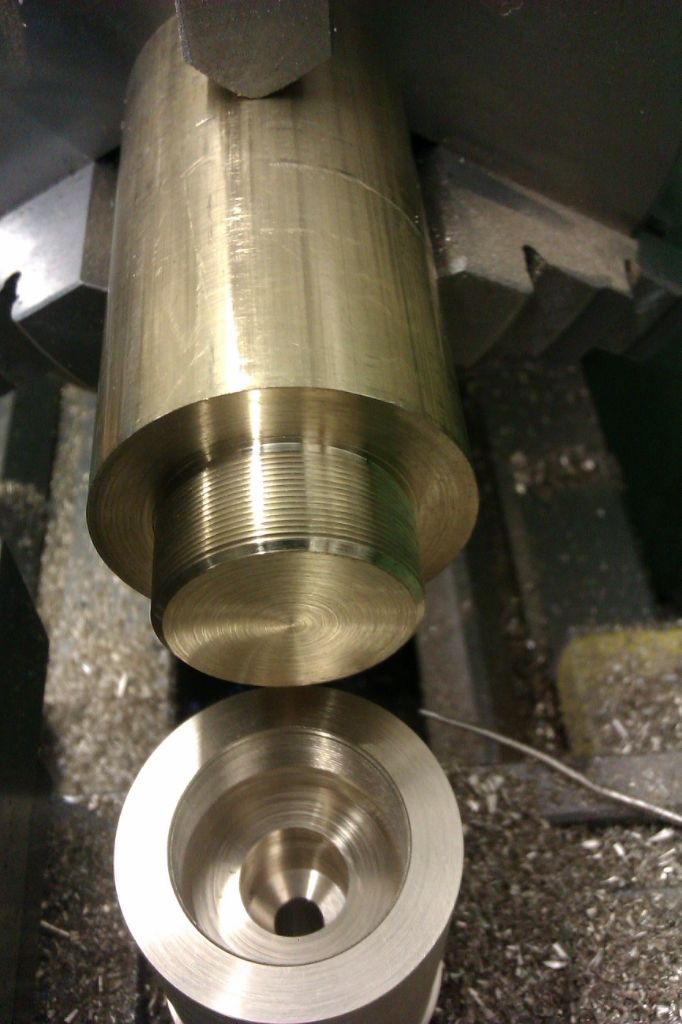

While the R/T was set up I used it to cut the two large radii on the stuffing gland

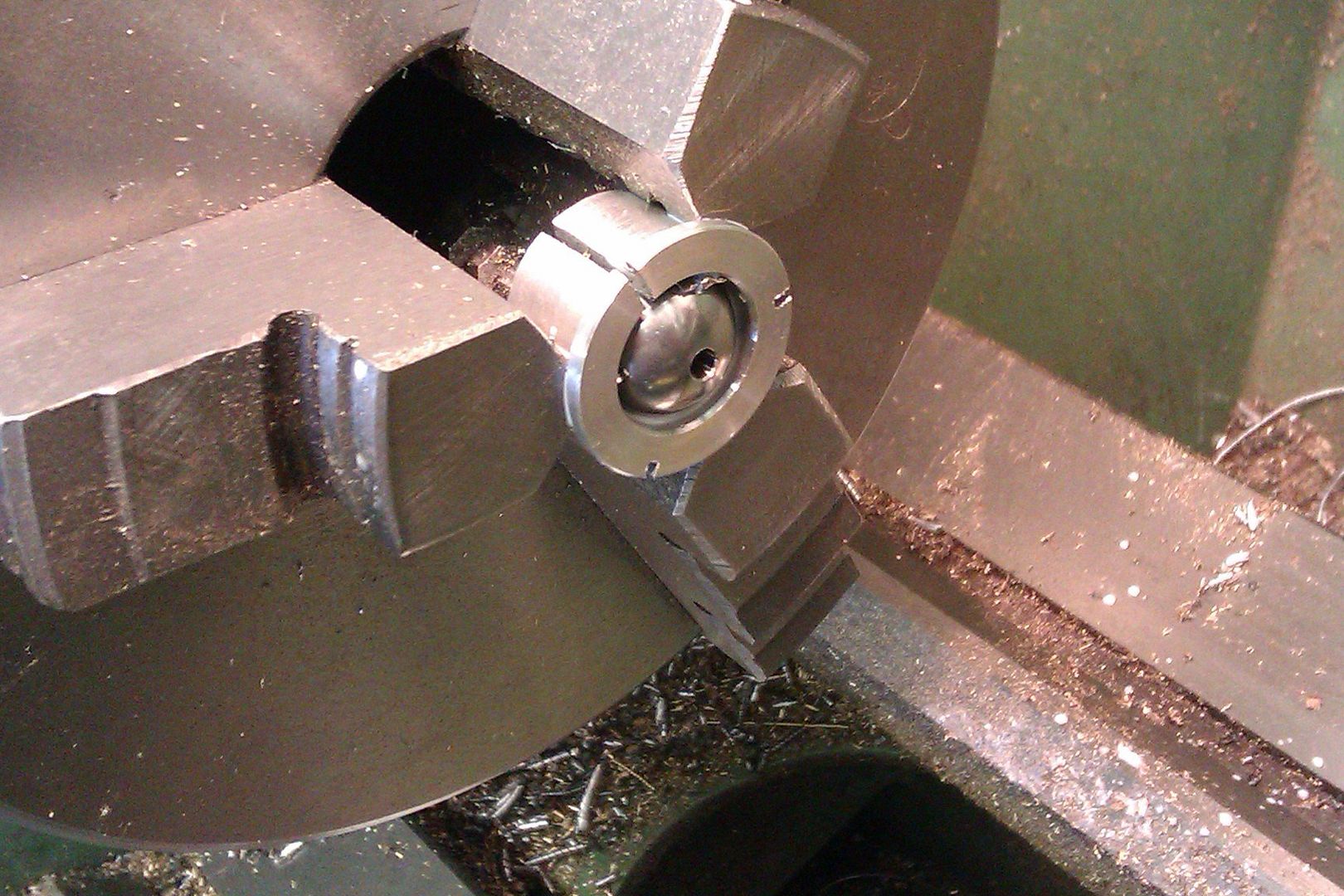

I decided to use commercial balls for the governor, these are 303 stainless and reasonably easy to drill in their supplied state. A split collet was used to hold them for drilling

These were loctited to the arms, I also made the small tee shaped legs that stop the balls dropping too far

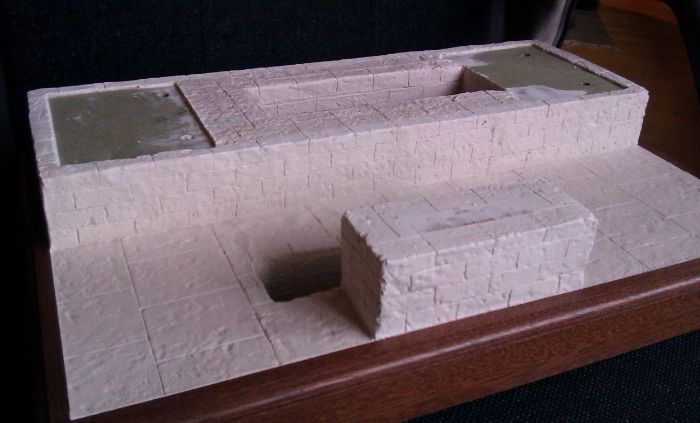

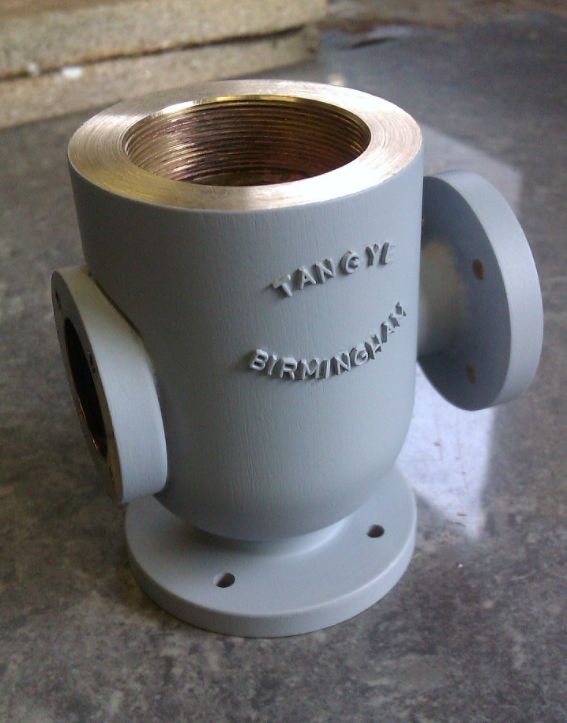

As this engine is only likely to run on air I added a finishing touch with some "Slaters" letters, these are 2mm high

And here are a few shots of all the bits fitted together, the eagle eyed of you (Jo) will also spot the bracket to support the other end of teh governor drive shaft.

J