fcheslop

Well-Known Member

Hi Zee, no doubt you'll get your own back when I eventually post :big: warts an all.Nice little loco are the plans available on the web?

regards Frazer

regards Frazer

mklotz said:It might have been easier to drill the holes for the crank pins before they were removed from their parent stock, nicht wahr?

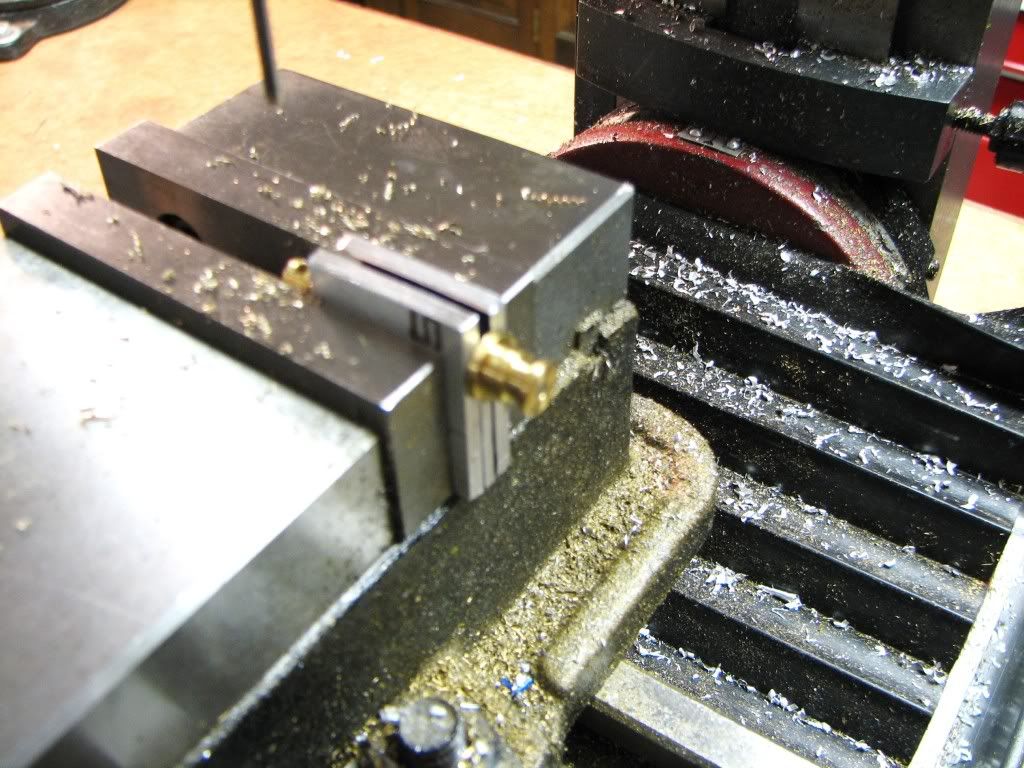

zeeprogrammer said:Cool. Two piston rod assemblies complete. Very cool.

Well...it will be very cool if they fit the cylinders.

I hope the old hands remember...getting a press fit is (for me) a sign of budding skill.

Now to drill the holes for the crank pins.

Severe bumness if I screw this up.

But I know bumness...and have made it a friend.

It's easy. Bumness likes vodka.

Slow going but going. Two piston rods in two weeks! But I'm going to have a loco!!!

P.S. Bumness has no taste. Any vodka will do. I keep the good stuff for me.

Man I enjoy this forum. Or the vodka does. Can you tell I'm celebrating?

mklotz said:Stimmt, ja sicher. Ich bin erfreut.

Sei ruhig, Dean.

Sehr Gut Zee :bow:Ganz gut. Nicht whar? Ja.

Enter your email address to join: