Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

zeeprogrammer said:To late for you but keep your eyes open...I provide many opportunities.

WE KNOW. ;D

Best Regards

Bob

zeeprogrammer said:To late for you but keep your eyes open...I provide many opportunities.

To late for you but keep your eyes open...I provide many opportunities.

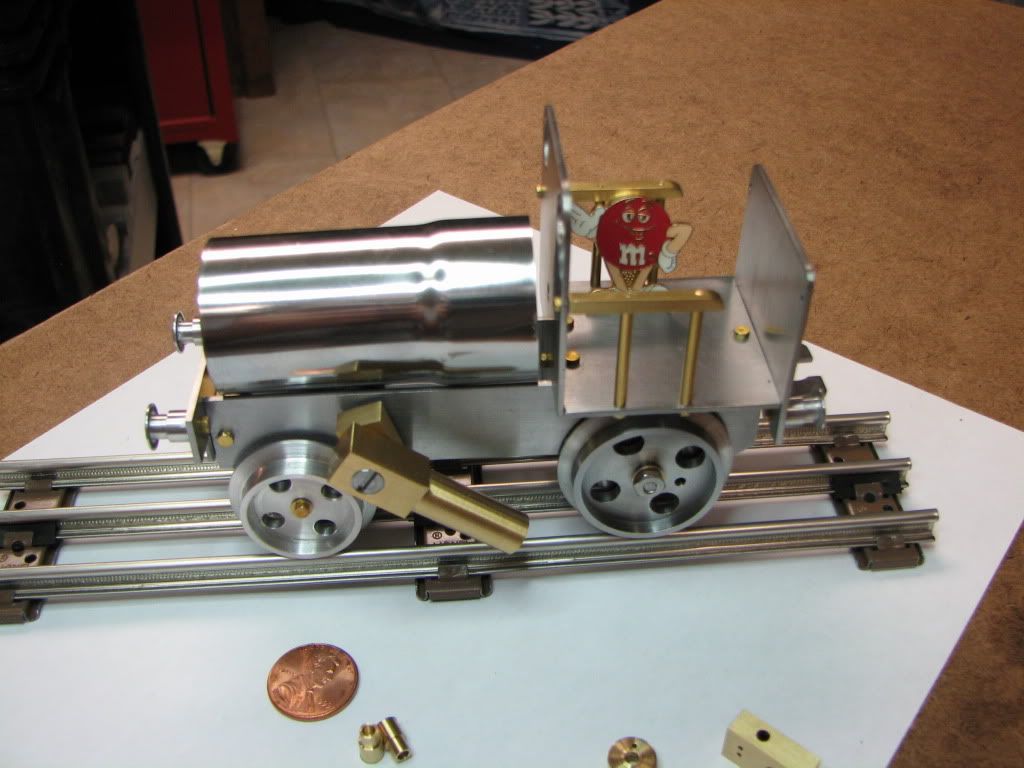

Deanofid said:you need to go buy some solder and flux before you can start that boiler

Just want to make sure you have enough rope.

Maryak said:WE KNOW.

Philjoe5 said:We'll be watching very closely now.

Philjoe5 said:Now I can go back to watching just closely.

Maryak said:I thought the burning smell may have been high speed flatulence.

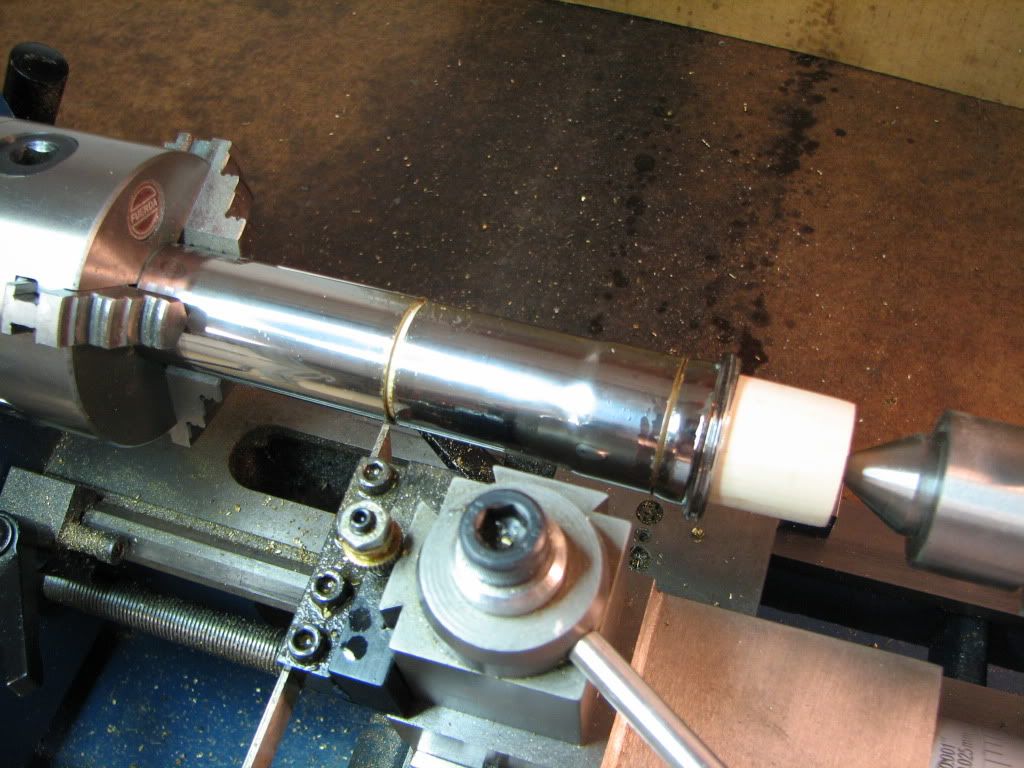

cobra428 said:I don't think you can solder to chrome plating.

arnoldb said:I see two tell-tale marks of spotted stripes behind the lathe on the wood... If it was oil and your better half's doing the laundry, she might complain

Enter your email address to join: