Things are reassembled with the machineable graphite valve and piston. I hate to say it, but the engine is no different now than it was with the cast iron valve and piston. It spins very freely, it acts as if it wants to run, but it is very difficult to find that "sweet spot" where it will pick up and keep on running by itself. I know that if you do find that "sweet spot" the engine will set there and tick over beautifully for about 20 minutes until the cylinder heats up to a point where there isn't enough temperature differential to keep it running. I may dick around a bit with different fuels, but unless changing to a hotter fuel does something remarkable, I'm done with this engine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brian does Ridders flame eater

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I've been thinking--which is probably a dangerous thing. I made my cylinder from 316 stainless to prevent any rust buildup inside the cylinder. (alcohol releases water when it burns). These flame licker engines depend on the heat differential between the flame they suck in and the cooler temperature of the cylinder to cool off the flame and create a vacuum. Someone pointed out that the thermal conductivity of stainless is only about 1/3 of the thermal conductivity of cast iron. I wonder if the poor performance of this engine could be caused by the cylinder material?--And yet Jan Ridders specifies stainless for the cylinder.

el gringo

Well-Known Member

- Joined

- Aug 30, 2010

- Messages

- 333

- Reaction score

- 175

I get very good performance with my gulpers using aluminum cyls and graphite pistons (see videos). When I build the Ridders engine I will use same.

Ray M

Ray M

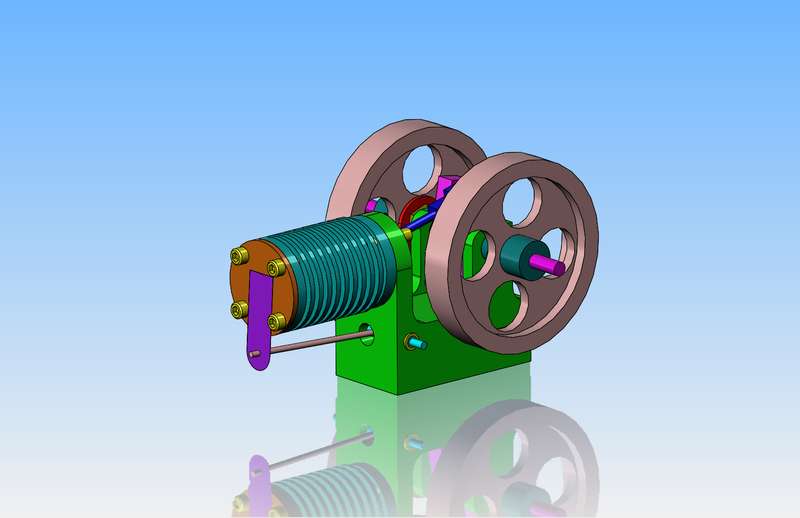

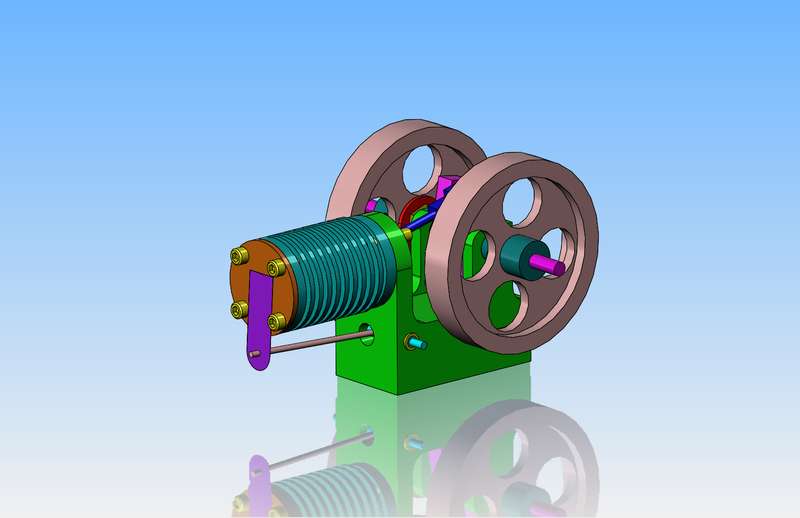

I want a dependable flame eater style engine. I modelled Mr. Senfts "poppin" engine today---

Cogsy

Well-Known Member

Mine is aluminium cylinder and graphite piston. The performance looks about the same as yours Brian, but it heats up very fast and only gives maybe 5-7 minute running time before it gets too hot to operate.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Brian, on the graphite, just wondering did you use locktight on the piston rod where it screws into the graphite? if so wondering how well it stuck to the graphite? never dealt with graphite but I figured it would be like trying to use elmers glue on Teflon....it just doesn't stick.

Yes, I did use Loctite. Loctite will hold fine in that application because there are no forces trying to turn the valve or the cylinder.

...----------------------

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Brian, the cutout on the base for the burner, in your opinion do you think it is necessary? even if you did not have the magnet would you think so? or is it more for looks? I know Jans plans had it there but wondered if it really helped keep the flame where it needs to be

You need the cut out in the base in order to get the burner down low enough.

Similar threads

- Replies

- 145

- Views

- 20K

- Replies

- 10

- Views

- 2K

- Replies

- 73

- Views

- 15K