Wouldn't it me wonderfully ironic, if all this inconsistent operation was simply a factor of having the fuel tank setting higher than the carburetor!!! When I get the new sparkplug from Rimfire in, and the fuel tank level corrected, I have high hopes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brian Builds the Kerzel Hit and Miss I.C.

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

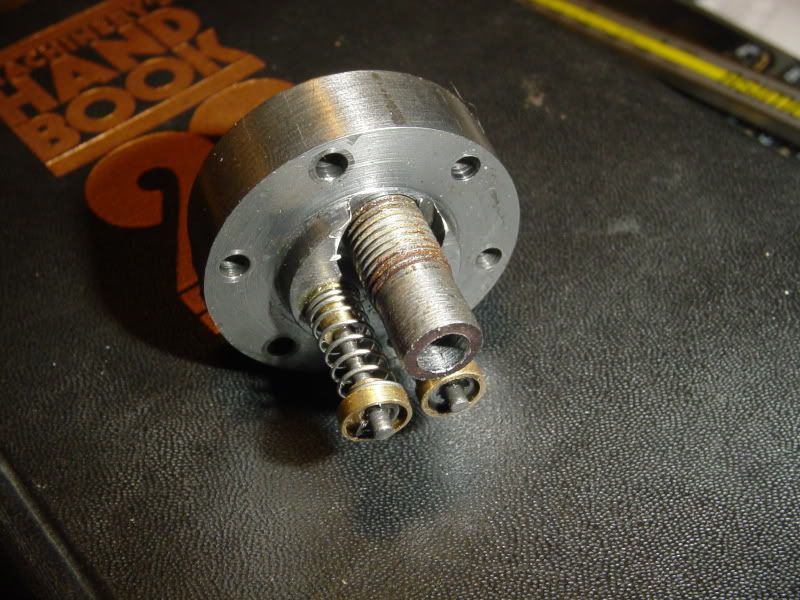

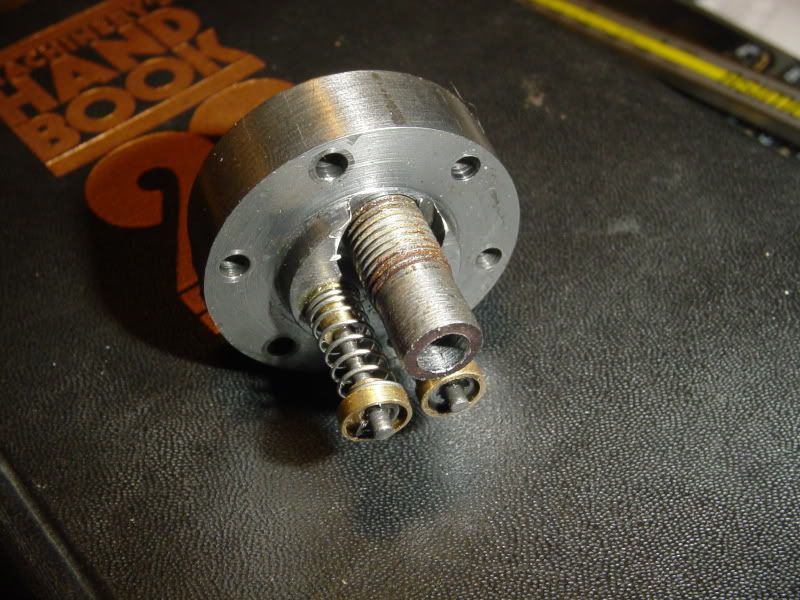

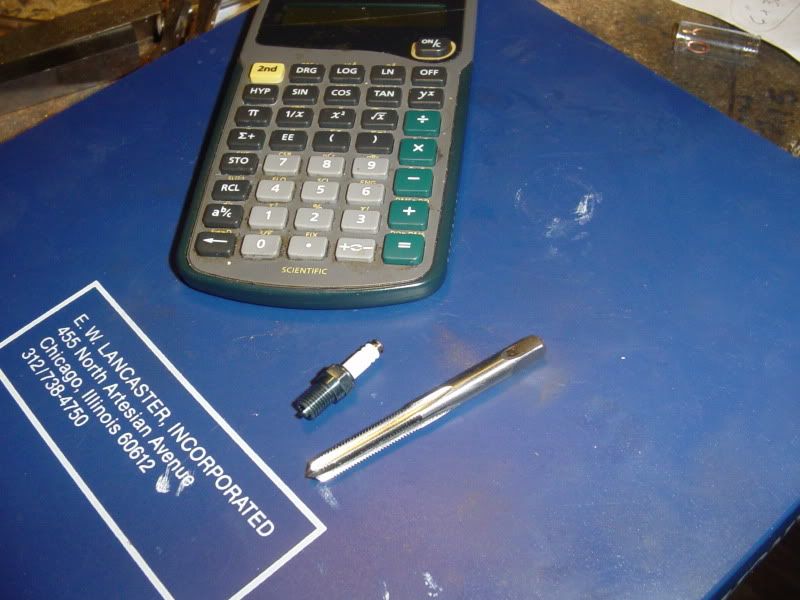

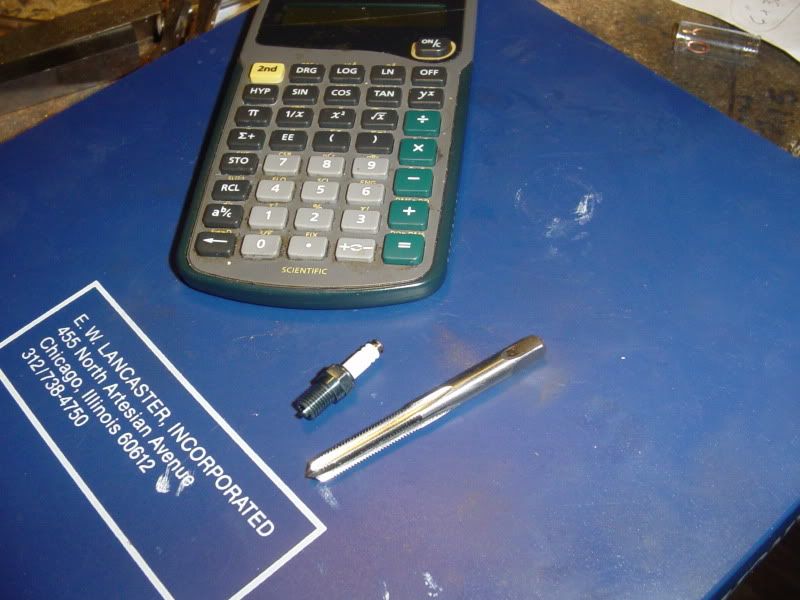

I'm playing the waiting game, waiting for my 1/4-32 Rimfire sparkplug to show up. While I'm waiting, I opened up the sparkplug hole in the cyl head from 5/16-24 to 3/8"-24 and threaded a peice of 3/8" rod I had laying around with a 3/8"-24 die. It screwed together, but for some reason seemed to be an "overly loose" fit. I then hunted around in my box of 10,000 bolts untill I found one with a 3/8"-24 thread which was a much better fit, so I drilled it out in preperation for the 1/4"-32 tap which I ordered with the sparkplug. The bolt is far longer than I need, but I won't trim it to length untill after I have the new sparkplug. Maybe while I wait I will build a proper size and height fuel tank!!!

I just received the smallest sparkplug I have ever seen, in the mail. This is the Rimfire VR2L from Morrison and Marvin Engineworks in Benton City, Washington. I ordered the 1/4"-32 tap with the sparkplug.

Well Bruce---Nothing ventured, nothing gained. I have installed the sparkplug in the head, and did a little jiggery pokery with my 12 volt coil, and it does fire. I took some advise from Gail in N.M. and tapped the head 3/8"-24 so I can put a larger "factory" plug in if necessary.

Well, we're mostly all back together again. We have a new VERY SMALL sparkplug from Rimfire, new bearing oilers, and a new gas tank--LOWER THAN THE NEEDLE VALVE!!!! I reassembled everythng, turned it over by hand---and had NO COMPRESSION! But wait---How can that possibly be??? It had tons of compression a week ago when I took it apart. While I had it all torn down, I decided that now was the time to use that peice of soft copper that some good hearted fellow from USA had sent me to use as a head gasket for the Webster engine I built last year. I hadn't used it, resorting instead to some treated cardboard gasket material. I made a beautifull soft copper gasket for the Kerzel. First thing I did was go upstairs and hijack the wifes Sunlight liquid dish detergent. I drooled a good quantity of it around the join between the cylinder head and the cylinder, and spun the engine with my electric drill.--Bubbles, bubbles---we got lots and lots of Bubbles. The copper head gasket does not seal worth a ----Well, lets just say it doesn't seal!! No big loss, I still have lots of the treated cardboard to build another headgasket for the Kerzel. I ordered a silicone boot to fit the Rimfire sparkplug this morning, along with two foot of high tension lead to get over to my 12 volt coil. So----Happy New Years to anybody still following this forever thread---Lets hope for a good runner in 2011.----Brian

Brian Rupnow said:Lets hope for a good runner in 2011.----Brian

I have no doubt!!

rudydubya

Well-Known Member

- Joined

- Nov 26, 2008

- Messages

- 337

- Reaction score

- 7

Brian, it's a great looking engine, looking forward to more of your videos. If you ever need an emergency head gasket, I've had good luck with short strips of Teflon pipe thread tape laid in a circular pattern around the top of the cylinder. I try not to overlap the pieces. Not pretty, but you can't see it when the head is on.

Regards,

Rudy

Regards,

Rudy

You probably could if the head or cylinder sealing surface were prepared to take a ring to seal it. This one is designed for a gasket. I am not about to dismantle the engine again for further machining to accept an o-ring.Peter. said:If you can use an o-ring as a piston ring why can't you use an o-ring to seal the head?

A good idea to consider in the future though Peter - then you could dismantle any number of times without disrupting the seal. Just out of interest Brian, did you anneal the copper gasket again once it was made? I guess it works on bigger stuff because you can torque it down a lot more and actually crush the copper?

Nick

Nick

There was no reason to anneal it. It was soft copper to begin with, cut out with shears and the holes were drilled. There was no extensive metalworking done to harden it. Its only .025" thickNickG said:A good idea to consider in the future though Peter - then you could dismantle any number of times without disrupting the seal. Just out of interest Brian, did you anneal the copper gasket again once it was made? I guess it works on bigger stuff because you can torque it down a lot more and actually crush the copper?

Nick

The Conley V8 uses o-rings for head gaskets, one on each cylinder. I was never able to make copper work. I think, in my case at least, the head bolts are too small to pull it down tight enough. Maybe if the copper gasket was really narrow i'd work. I use paper gasket material. It works well for me. Some suggest Teflon.

The silicone boot on the spark plug will be plenty cool but if you want a temporary boot use a piece of silicone model air plane gas line, 1/8 inch. If you use 1/8 inch dia test lead wire for sparkplug wire you can stick it in the silicone gas line boot and you're done, no mechanical attachment needed. It's a good way cuz you can see the spark through the silicone to see if the ignition is working. The gasline comes in colors too.

Just my two cents.

The silicone boot on the spark plug will be plenty cool but if you want a temporary boot use a piece of silicone model air plane gas line, 1/8 inch. If you use 1/8 inch dia test lead wire for sparkplug wire you can stick it in the silicone gas line boot and you're done, no mechanical attachment needed. It's a good way cuz you can see the spark through the silicone to see if the ignition is working. The gasline comes in colors too.

Just my two cents.

Copper rings need to be annealed with each use.

Heat bright red and quench in water - this makes them putty soft.

Copper age and work hardens quite rapidly. (depends on grade)

I have a piece of copper wire which annealed is like spaghetti but you can actually feel it work harden as you flex it.

Ken

Heat bright red and quench in water - this makes them putty soft.

Copper age and work hardens quite rapidly. (depends on grade)

I have a piece of copper wire which annealed is like spaghetti but you can actually feel it work harden as you flex it.

Ken

Sigh of relief!!! I have my compression back. Pulled out the copper gasket and replaced it with the treated cardboard gasket material. I am waiting now for my sparkplug boot and ignition wire, fingers crossed!!! My belief is that on a small engine like this, where the head is held in placewith six #5-40 shcs., you simply can't apply enough torque to get a seal on a copper gasket no matter how soft it may be.

- Joined

- Jul 16, 2007

- Messages

- 2,985

- Reaction score

- 1,051

Hi Brian,

You can use a copper gasket as a head gasket but it takes a little trick. I also found out early on that with small screws you can't get enough compression pressure to actually seat the copper gasket no matter how annealed it is. Here's what you have to do.

Make up a plate, aluminum is fine, with a small groove machined into it. The groove can be .045 wide and .025 deep. Now make another plate to locate over the first one with a small ring on it. The ring would be smaller by whatever thickness of copper you are using. Anneal the copper and squeeze it between the plates to form a small ridge in the gasket. Then when you tighten the head bolts it will compress the ring and form a very good seal.

I replicated what they use for head gaskets on Japanese dirt bike engines.

Why go to all this trouble you ask? Because you can use thinner material for the gasket and it will not burn out or be affected by gasoline and oil.

gbritnell

You can use a copper gasket as a head gasket but it takes a little trick. I also found out early on that with small screws you can't get enough compression pressure to actually seat the copper gasket no matter how annealed it is. Here's what you have to do.

Make up a plate, aluminum is fine, with a small groove machined into it. The groove can be .045 wide and .025 deep. Now make another plate to locate over the first one with a small ring on it. The ring would be smaller by whatever thickness of copper you are using. Anneal the copper and squeeze it between the plates to form a small ridge in the gasket. Then when you tighten the head bolts it will compress the ring and form a very good seal.

I replicated what they use for head gaskets on Japanese dirt bike engines.

Why go to all this trouble you ask? Because you can use thinner material for the gasket and it will not burn out or be affected by gasoline and oil.

gbritnell

Similar threads

- Replies

- 413

- Views

- 38K

- Replies

- 356

- Views

- 54K