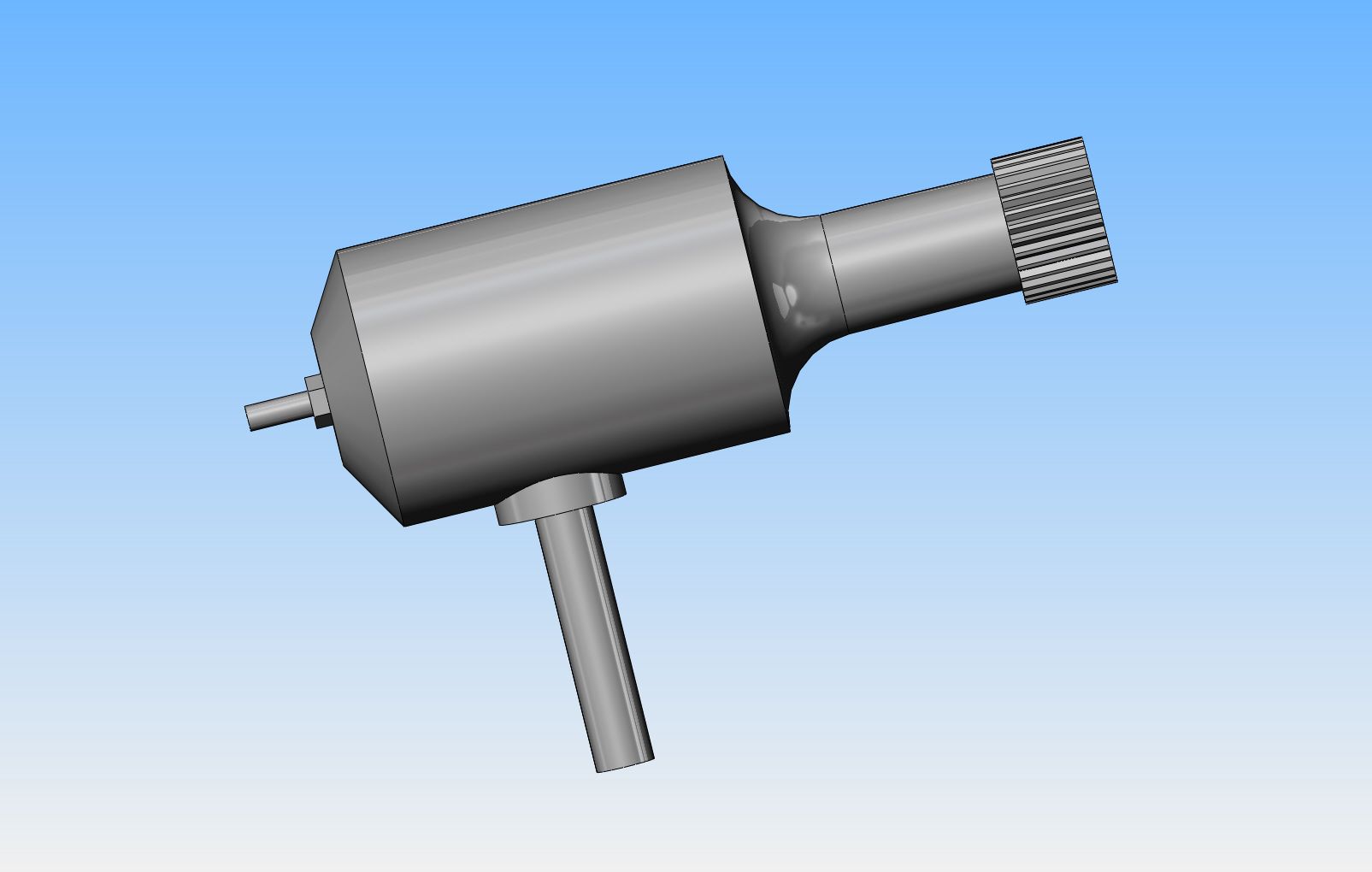

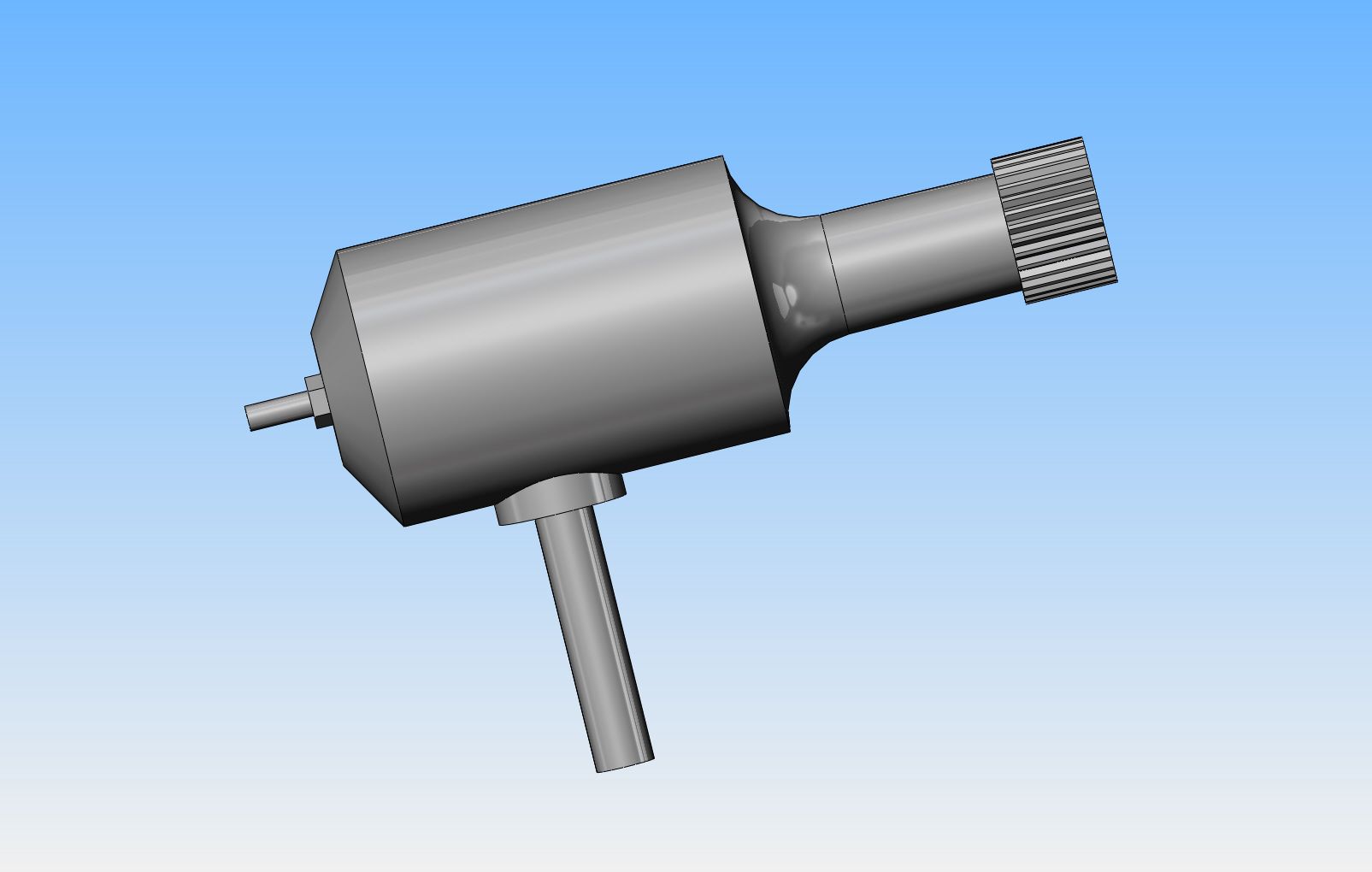

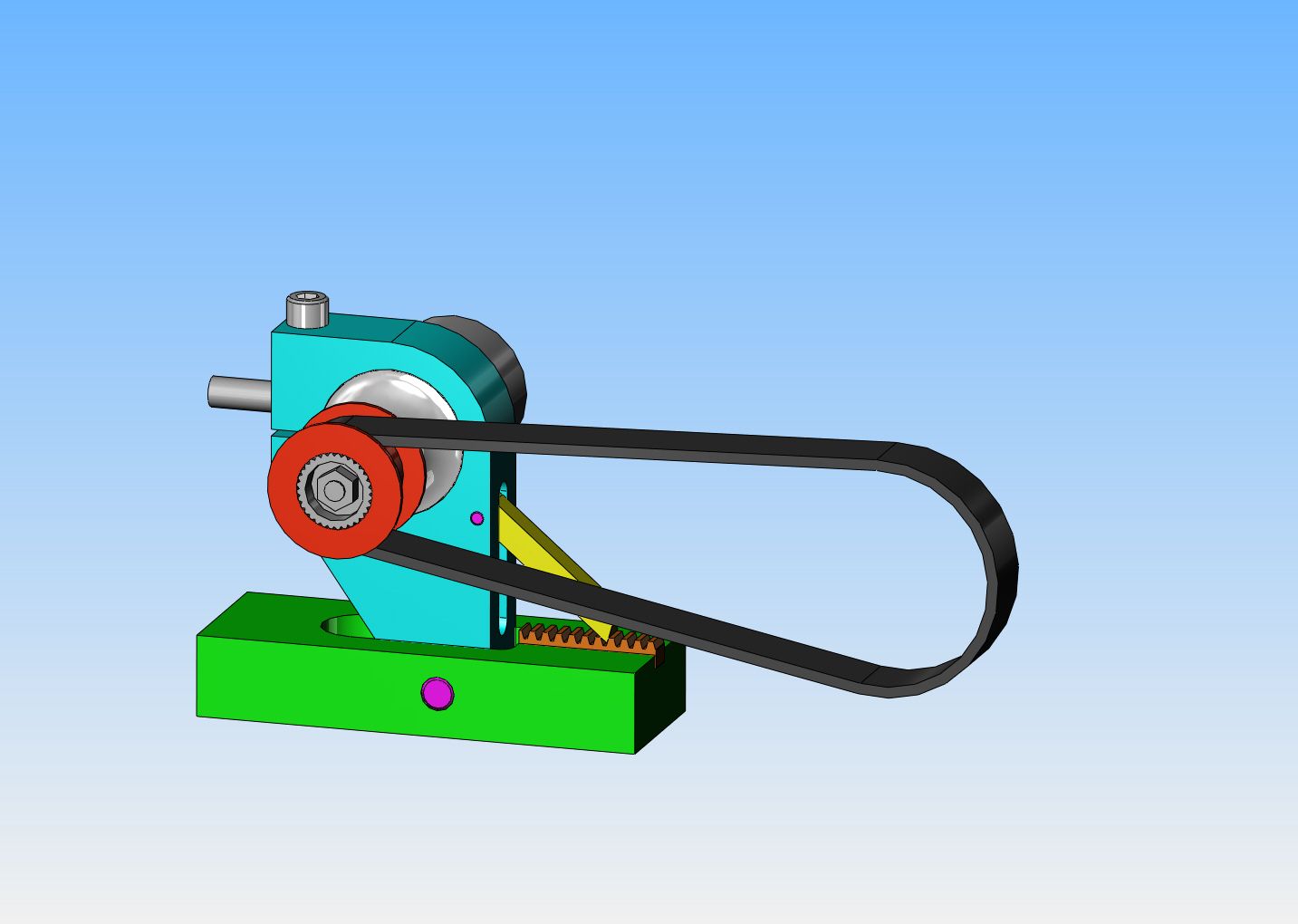

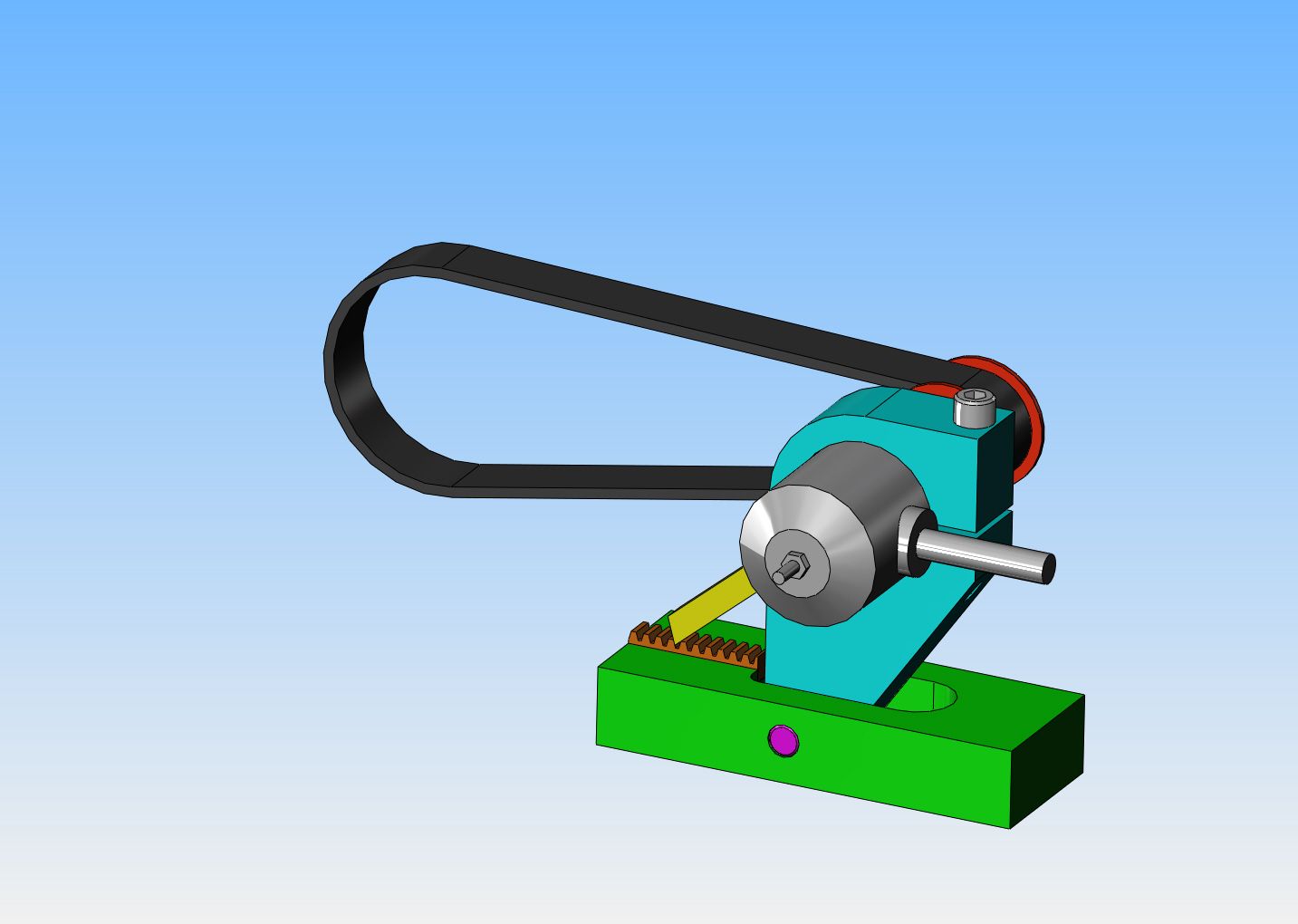

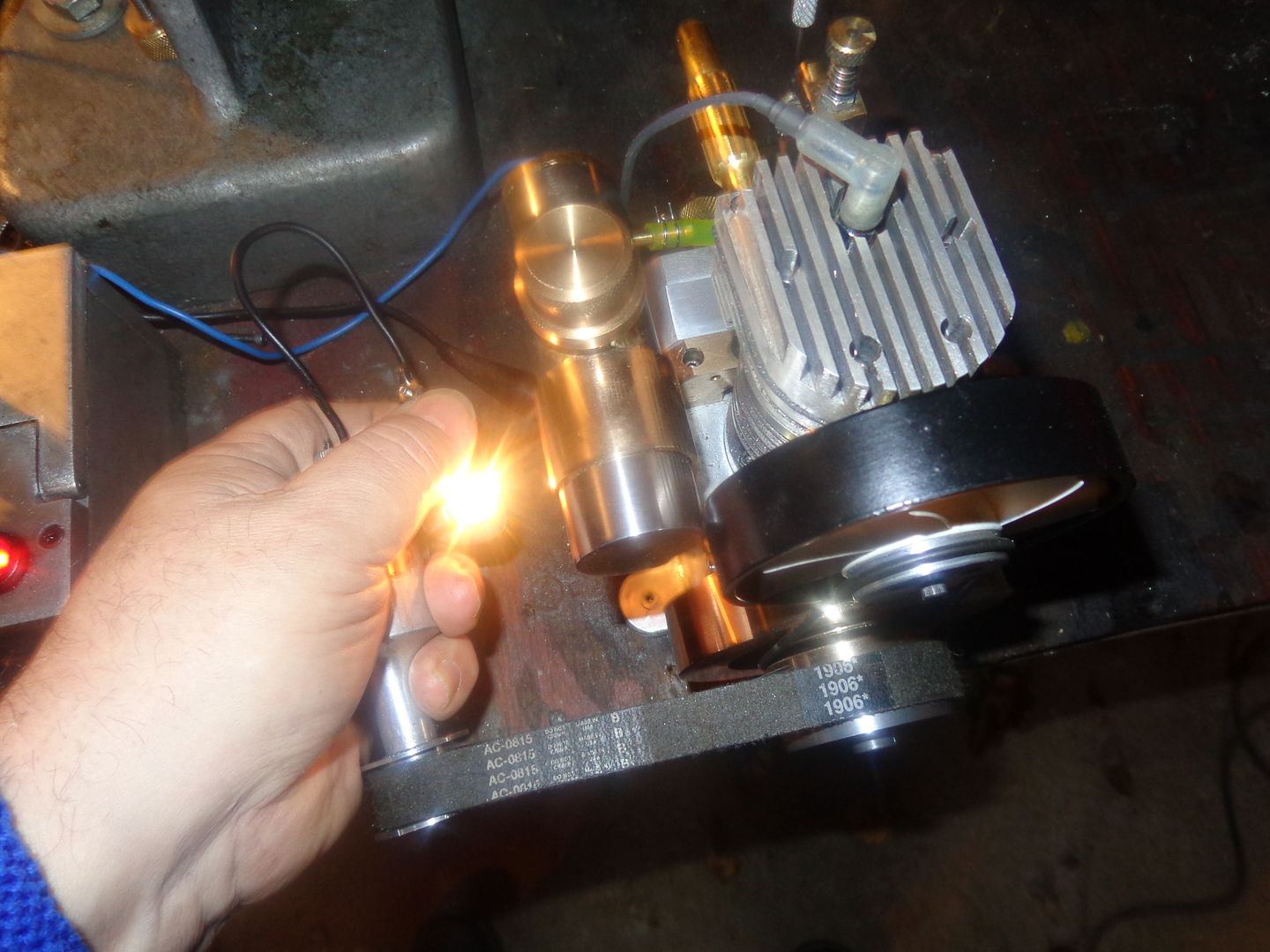

Today I tested the bicycle generator (dynamo) that was sent to me by a fellow member. Not knowing what voltage this thing produces, and not having a voltmeter, I robbed a 2.9 volt rated battery out of a flashlight and jerry rigged a pigtail and alligator clamp to the bulb and the output terminal of the dynamo. I have a small cogged drive belt that I salvaged off something, and holding a 1" pulley in the milling machine chuck and pulling the belt tight I was able to light the flashlight bulb. This satisfies me that the dynamo does indeed produce electricity. It did need to be rotating at a pretty respectable rpm to light the bulb, but I don't have actual figures on the rpm. I intend to machine a 0.8" diameter flat pulley with side flanges on it to press fit onto the knurled end of the dynamo, and use the same belt that is in the picture to drive the dynamo from the 2" diameter starter hub on my side valve engine. This will give me a ratio of 2.5:1, so if the engine is rotating at 1500 rpm, the dynamo will be revolving at 3750 rpm. I have to design and fabricate a mounting base for the dynamo and a belt tightening mechanism, as I want the dynamo and its base to be a "composite unit" separate from the engine.--Stay Tuned!!!