Hi

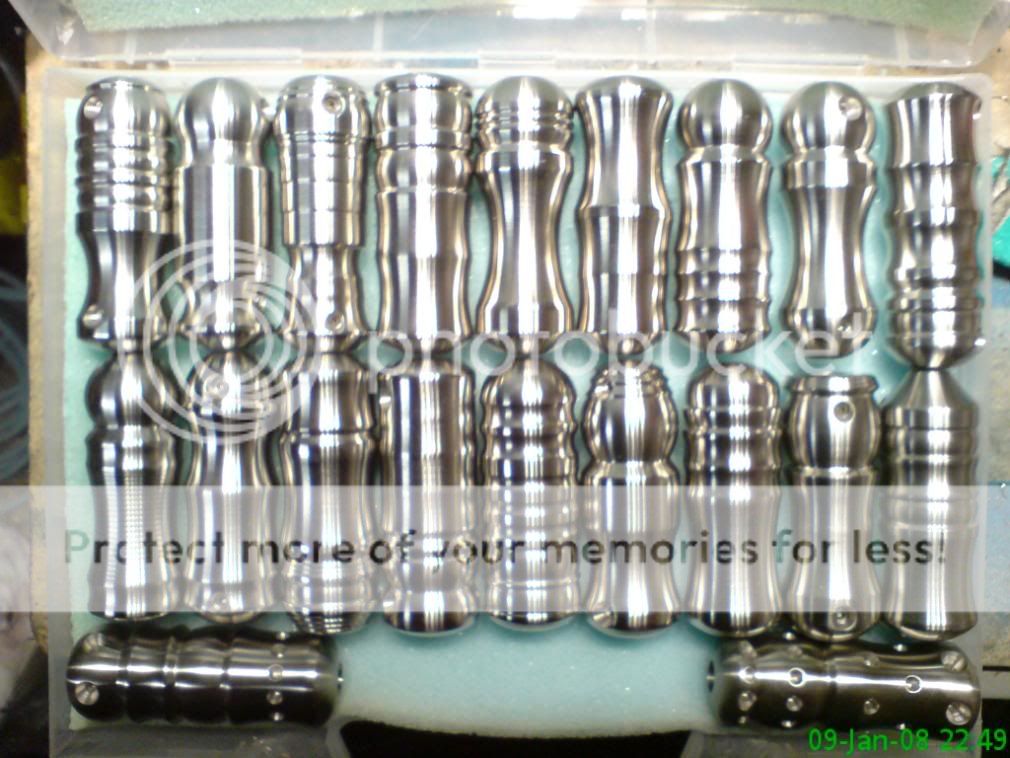

High on my list of things to do is the making of a ball turner as amply demonstrated in several posts on this forum. Sourcing suitably sized pieces of steel has been one problem. When my wife asked me what I would like for xmas I quickly replied a ball turner would be nice. : I think I had best skip the next part of the conversation in case SWMBO happens to spot this post. Anyway I came across this at RDG tools.

I think I had best skip the next part of the conversation in case SWMBO happens to spot this post. Anyway I came across this at RDG tools.

http://www.rdgtools.co.uk/acatalog/MYFORD_LATHE_USERS_NEW1.html

As I am a Myford owner I decided to send off for one. A bit expensive at £42.00 but it bolts straight on to my lathe with a pre set centre height and will save me quite a bit of construction time. I haven't had a play with it yet, Iv'e got to wait for santa to bring it (even though its on my credit card : ) I'll report back after the festivities.

) I'll report back after the festivities.

Cheers

Rich

High on my list of things to do is the making of a ball turner as amply demonstrated in several posts on this forum. Sourcing suitably sized pieces of steel has been one problem. When my wife asked me what I would like for xmas I quickly replied a ball turner would be nice. :

http://www.rdgtools.co.uk/acatalog/MYFORD_LATHE_USERS_NEW1.html

As I am a Myford owner I decided to send off for one. A bit expensive at £42.00 but it bolts straight on to my lathe with a pre set centre height and will save me quite a bit of construction time. I haven't had a play with it yet, Iv'e got to wait for santa to bring it (even though its on my credit card :

Cheers

Rich