Thank you John ;D ; This is the first flywheel I'm making in terms of milling out spokes and so on from solid stock. I was surprised at how much thinking it required! I've seen at least one of your "re-shaped" flywheels as well, and it was both amazing and inspiring what you came up with to recover from an "oops"!

Hurry up and Wait Carl, you're in the army now :big:. Thank you, but I cannot take credit for the tip on using the wire; I came across references to using it multiple times while doing researches and reading on home/model engineering.

Thanks Dean ;D. Like I said above to Zee; the races for parallels is an old machining practice. I get mine for free; Make friends with your local auto workshops and auto electricians; they replace and then throw away a lot of them!. Just takes a punch and hammer to get two parallels and a handful of ball bearing balls from an old bearing. And in a squeeze, you can make toolbits from those races; it's hard steel ;D

Joe, Thanks ;D

I had a chance to get some more done after work today ;D

The flywheel still needed a hole drilled and threaded in it for a grub screw (I think set screw for those from the USA ???) to tighten it to the main shaft.

This added a whole new angle to things; the hole had to be at an angle... After a lot of thinking about spacers and protractors and such, I looked at at the clamping kit, and those step-blocks had about the right angle to them - across the steps. The flywheel would need protection from the edges on the steps of the step blocks; a strip of leather would take care of that. Long story short, here is what I did, with the arbour I made earlier set so I could tighten the flywheel against the step blocks:

This setup will not do for milling, but for drilling, it is fine.

Then center drilled the flywheel hub; the chuck barely misses the flywheel rim. :

A 2.5mm drill easily followed into the center hole; I could "feel" when it broke through before it hit the screw in the arbour. Then a VERY careful tapping operation followed; earlier on in the build I said I'm not afraid of those big M3 taps anymore; well, I'm not, but this is at an awkward angle. My taps were barely long enough to do the tapping without resorting to things like extensions and so on...

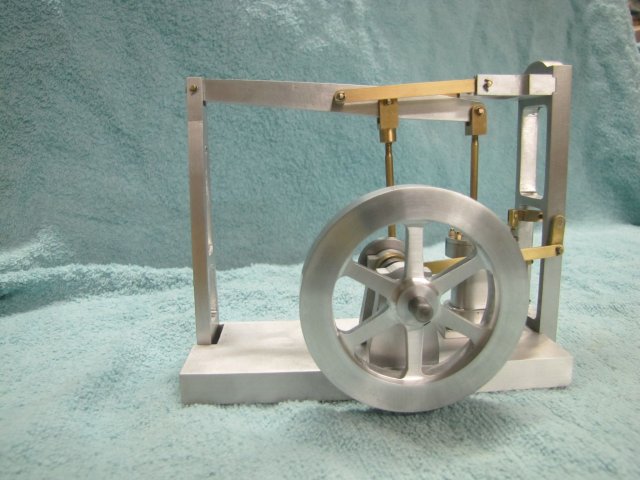

After 2 hours of filing and sanding - some sanding in the lathe and a lot of filing and sanding in the vise, I decided it will have to do:

Then I fed the swarf magnets - they were clunking around their food bowls, and got right back to the shop.

A lot of fiddling with small bits of wire and needle-nose pliers happened. VERY carefully; I didn't want scratches from the pliers running onto the build parts.

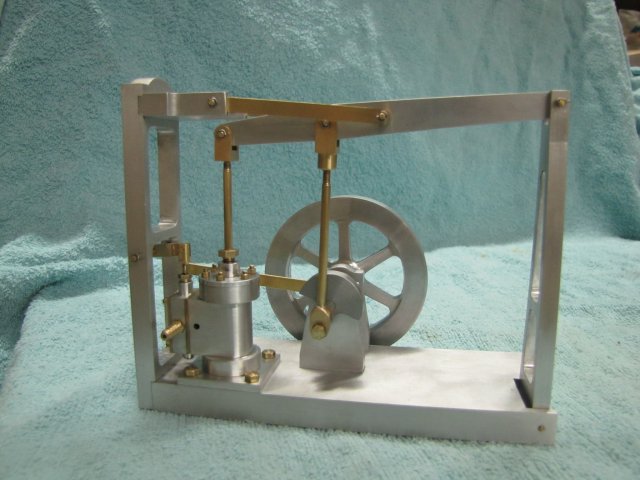

I ended up with this:

The last photo above shows an inexcusable blemish; when I trial fit all the parts, the top cylinder head would only go on properly in one specific orientation - not because of the bolts, but the ridge on the cylinder head is a very close match to the bore, and I marked that orientation with a permanent marker. I forgot to wipe off the ink!.

And even worse, even though it is not referenced in the plans, I suspect that there are lock-nuts needed where both the connecting rod joins it's fork, and the piston rod joins it's fork; especially for last named; the piston could easily rotate while running and screw the rod in or out on the fork, resulting in a jam-up.

Does it run ??? - ;D ;D ;D ;D ;D YES! - I gave it a quick test-run on 20psi of air and it runs!. No video yet though. I need to make up a small adapter fitting first; the steam connector is too small for my piping, and I had to keep the air hose jammed against the valve block face with both hands. And it was late; I could only run the compressor quickly for the test; my neighbours are asleep already. Hopefully I can make the video tomorrow afternoon after work.

Alas... The Bling Fairy didn't visit, so I had to do a bit of a manual cleanup; mostly on the brass parts. As a test, I applied one of these "new-fangled" high tech polymer car waxes to all the parts to see if it would help in retaining the finishes. I'll report back on the results of that in a couple of months.

Regards, Arnold ;D ;D ;D