- Joined

- Mar 3, 2008

- Messages

- 243

- Reaction score

- 20

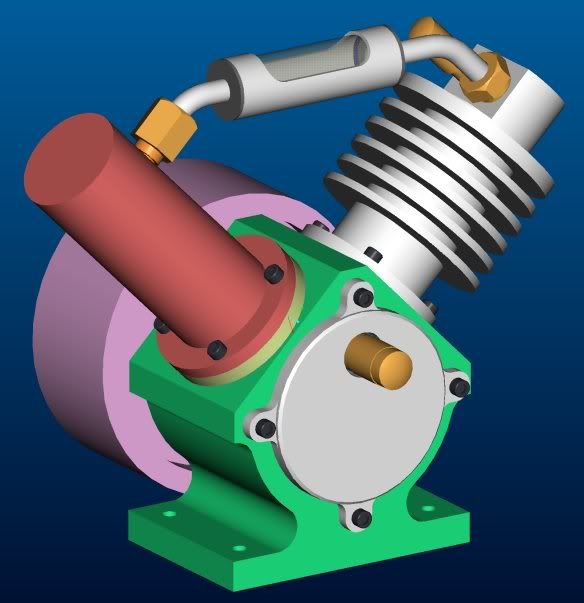

Time for a new project. I have had my Lathe & mill for about 3 years now, and I think it is time to design my own engine. I have decided to build an Alpha-type Hot-Air Engine.I was going to call this the "Alpha V" but after my wife saw the drawing, she put up 2 fingers and said "Victory" so the name will stick. I could not find much information on this type of engine, except for some research done at Gazi University in Turkey. http://journals.tubitak.gov.tr/engineering/issues/muh-00-24-2/muh-24-2-2-98073.pdf

I also found this interesting animation on the web.

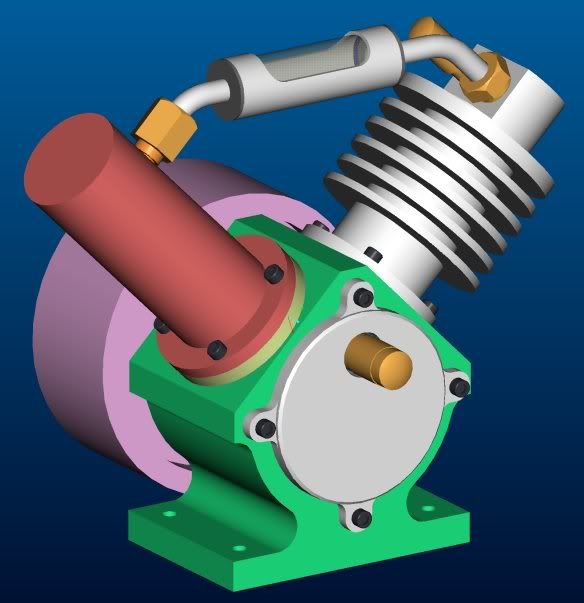

So I dusted off a old copy of Pro/Engineer and started to put some ideas together.Here is a picture of the model created in Pro/E:

After spending months designing this engine, I really appreciate all the people who make engine plans available on the net. This was a lot of work compared to just following a set of plans. I had to make a lot of assumptions and I Incorporated a lot of ideas I found from many different sources. I do not know if this design will even run, but I sure did learn a bunch of stuff on the way, and if it fails, it will make a nice doorstop! I will try to describe some of these design points along the way.

One of the most satisfying moments came when I finally got the motion analyses to run on the computer. It was like getting a model to run the first time. :big: Here is a short movie of the motion analyses.

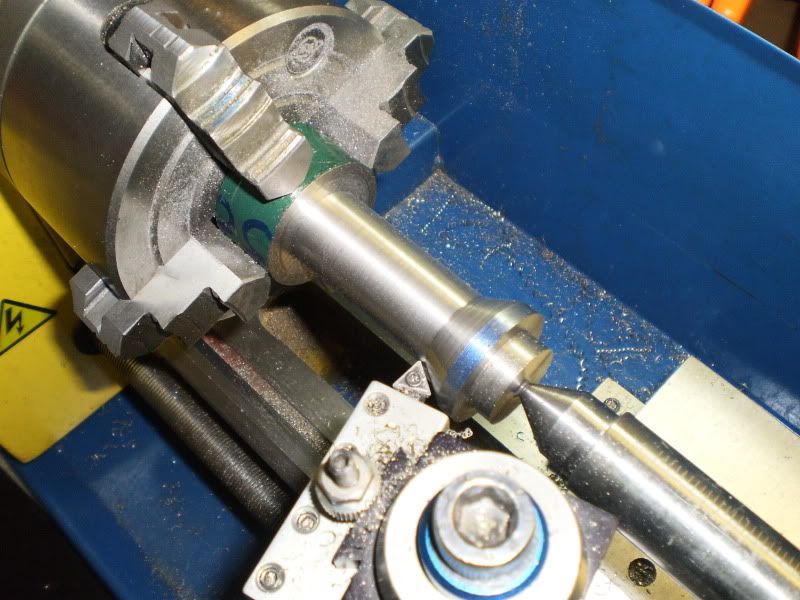

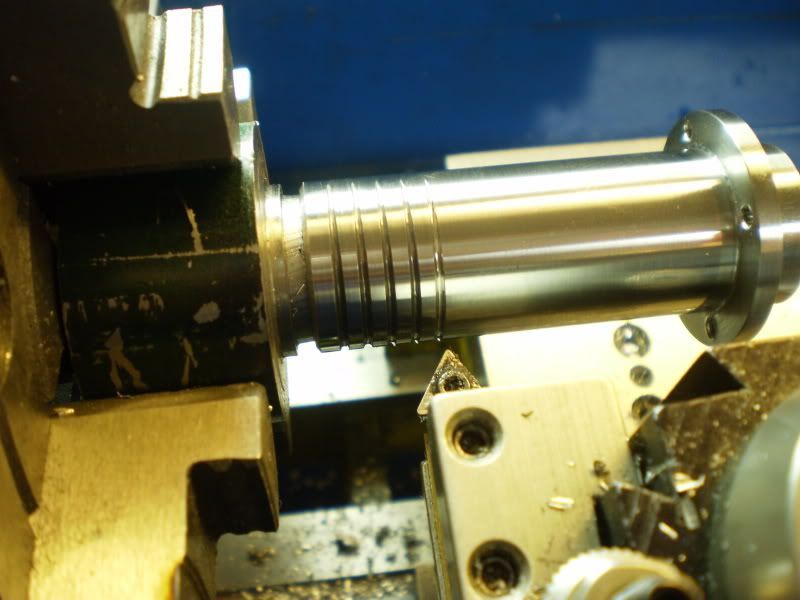

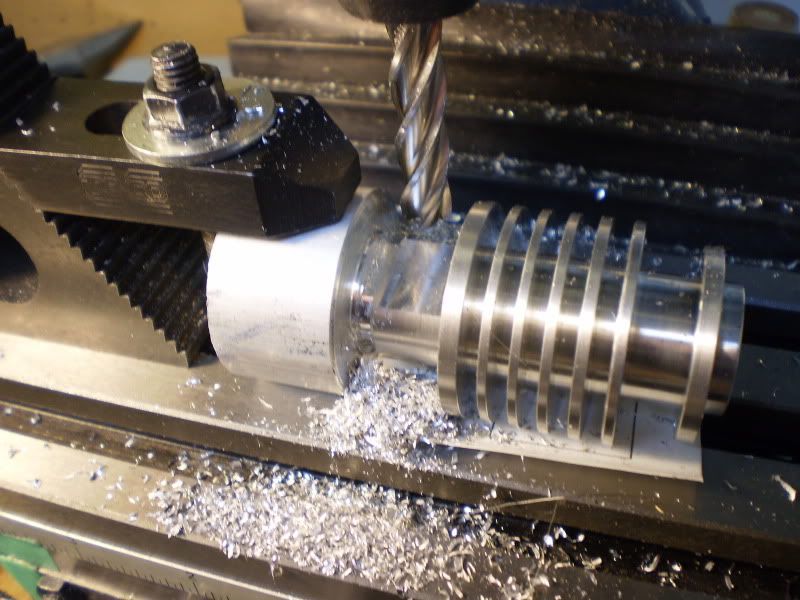

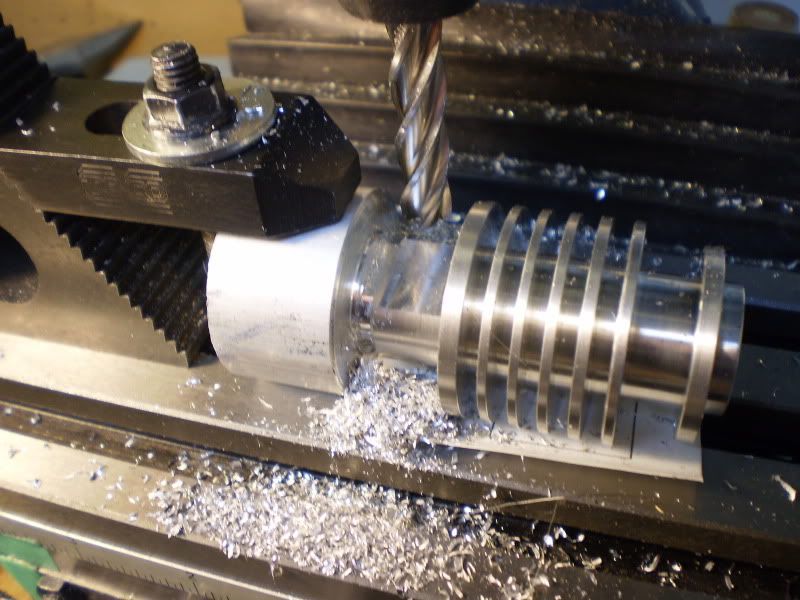

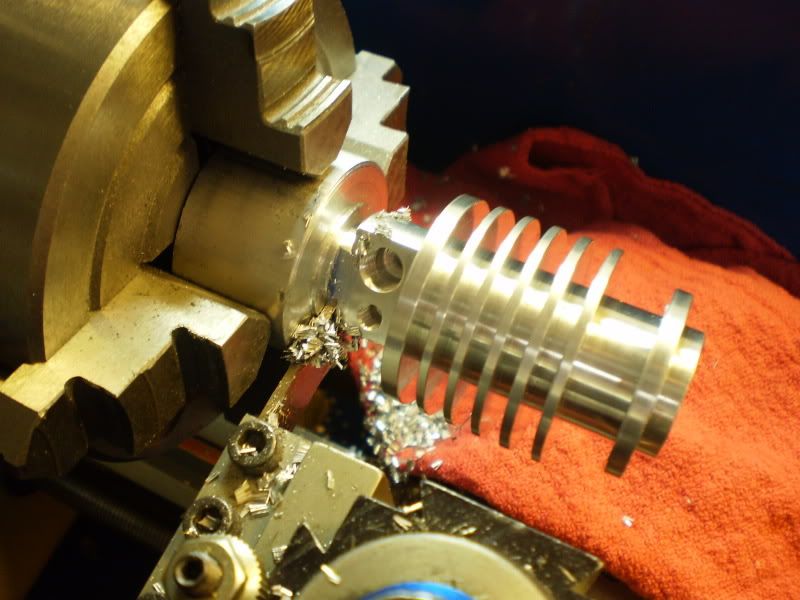

Time to cut some metal. I started off with the cold cylinder, nothing too exotic here, just bore and cut some fins on some Ali. There are 2 threaded holes on the top of the cylinder. The large one is for the Regenerator (Economizer) and the other one is a port to release the compression in the cylinders for testing. This port can also be used to pressurize the engine. These type of engines will develop more power if the working gas is pressurized. Using Helium will increase the power even more.

Cutting the fins;

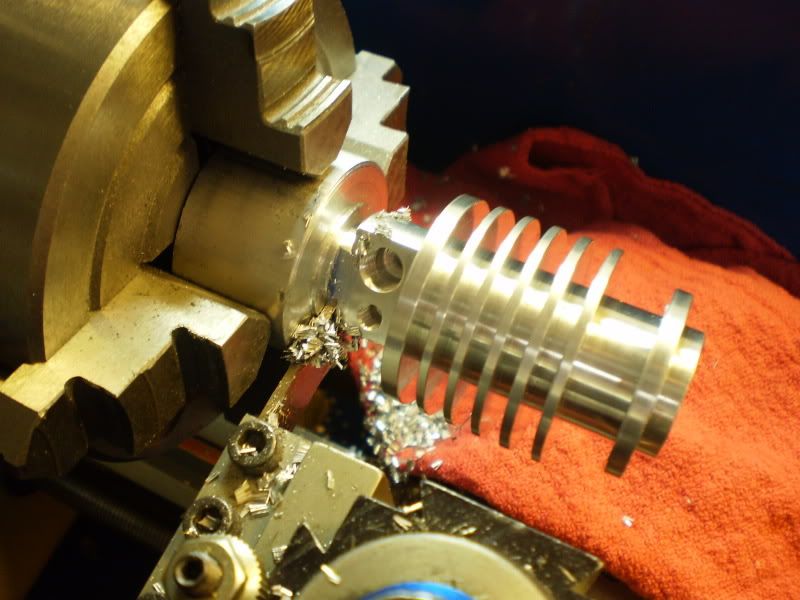

Boring the cylinder;

Milling the flat;

Parting off;

Next will be the hot cylinder.

IronHorse

I also found this interesting animation on the web.

So I dusted off a old copy of Pro/Engineer and started to put some ideas together.Here is a picture of the model created in Pro/E:

After spending months designing this engine, I really appreciate all the people who make engine plans available on the net. This was a lot of work compared to just following a set of plans. I had to make a lot of assumptions and I Incorporated a lot of ideas I found from many different sources. I do not know if this design will even run, but I sure did learn a bunch of stuff on the way, and if it fails, it will make a nice doorstop! I will try to describe some of these design points along the way.

One of the most satisfying moments came when I finally got the motion analyses to run on the computer. It was like getting a model to run the first time. :big: Here is a short movie of the motion analyses.

Time to cut some metal. I started off with the cold cylinder, nothing too exotic here, just bore and cut some fins on some Ali. There are 2 threaded holes on the top of the cylinder. The large one is for the Regenerator (Economizer) and the other one is a port to release the compression in the cylinders for testing. This port can also be used to pressurize the engine. These type of engines will develop more power if the working gas is pressurized. Using Helium will increase the power even more.

Cutting the fins;

Boring the cylinder;

Milling the flat;

Parting off;

Next will be the hot cylinder.

IronHorse