mikegw1961

Well-Known Member

- Joined

- Jan 29, 2012

- Messages

- 53

- Reaction score

- 7

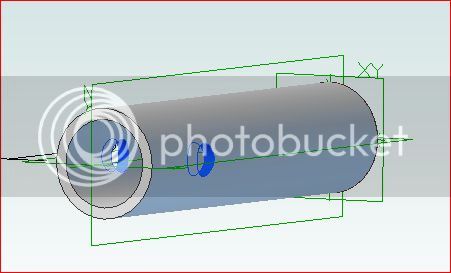

I have just started the trial in Alibre and i am trying to find out how to draw a hole through the side of cylinder like a tee bar handle.

I get an error that I cannot select the plane

:wall::wall::wall:

I get an error that I cannot select the plane

:wall::wall::wall: