Motormagican

Well-Known Member

- Joined

- Oct 21, 2012

- Messages

- 82

- Reaction score

- 45

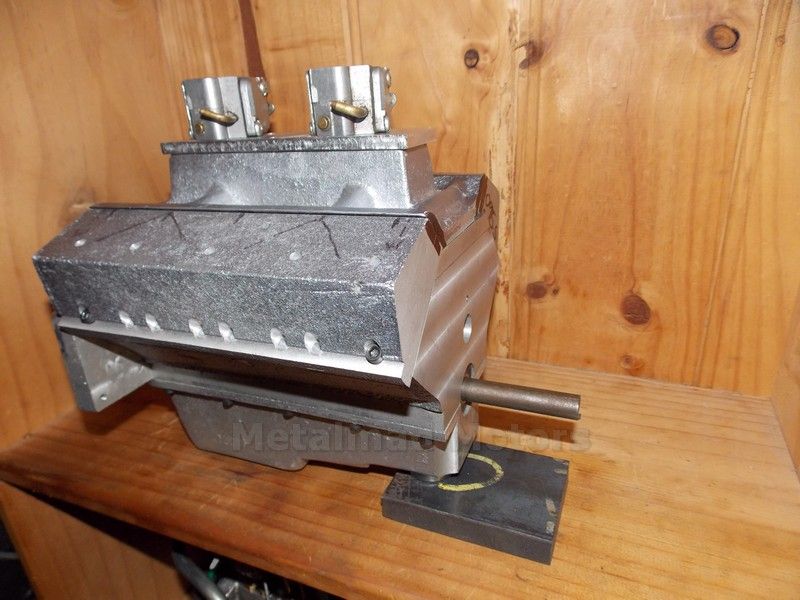

Pete, that engine is going to look real good once finished. Shoot!! It looks great now. I will keep following you progress.

Enter your email address to join: