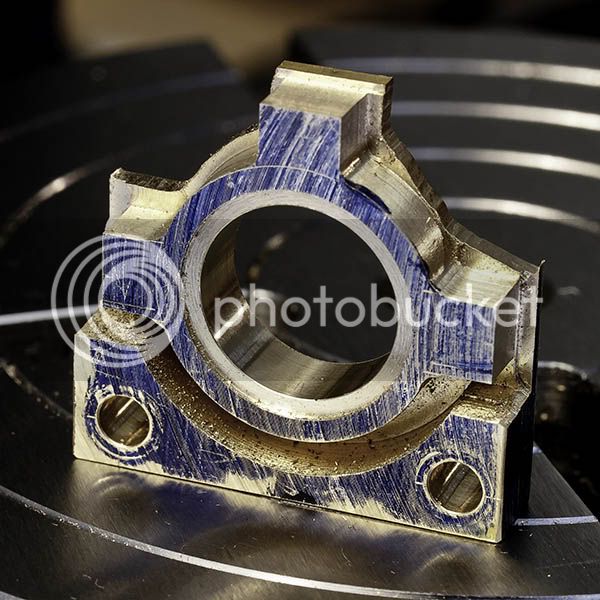

Making nuts was driving me, well, nuts so I quit and started on the eccentric strap. The bearing is machined with the two halves soldered together as usual. The join is central to make it easy to find the centre for drilling and reaming the reference hole. I decided to mount the part to a plate to avoid stressing the soldered joint (my last one fell apart:wall and to make it easier to mount in the four jaw chuck later. First pic is of the setup ready to go.

and to make it easier to mount in the four jaw chuck later. First pic is of the setup ready to go.

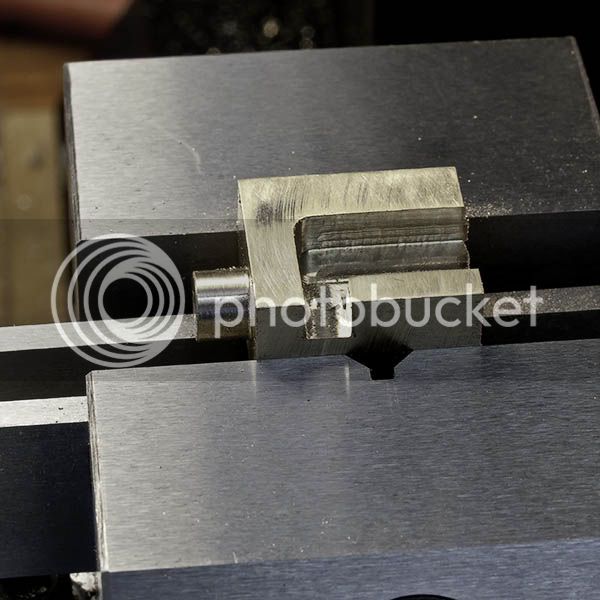

The strap is quite small and needed small corner radii and hence a 2mm diameter cutter. This makes for slow work and the constant fear of the cutter breaking. The depth of cut was .005" so at least the feed was quick.

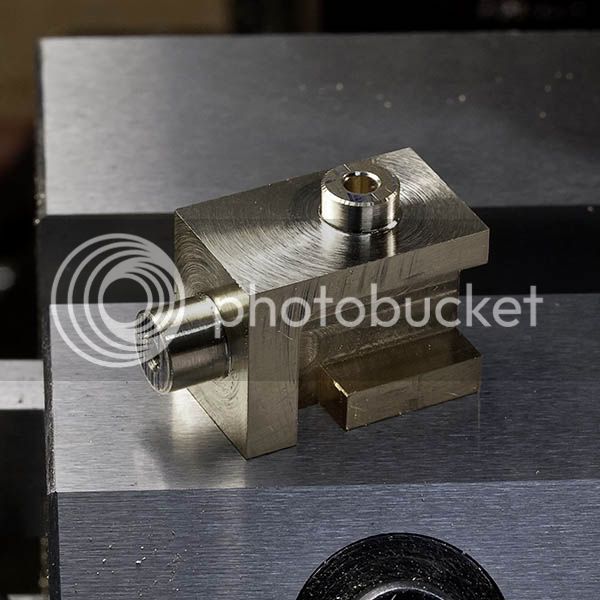

Last shot shows the progress so far, the milling nearly done then off to the lathe to size the bore. The little piece of brass shim is a very short homemade ruler so I could measure how deep the cut had gone without winding the cut off at all.

More tomorrow with a bit of luck

The strap is quite small and needed small corner radii and hence a 2mm diameter cutter. This makes for slow work and the constant fear of the cutter breaking. The depth of cut was .005" so at least the feed was quick.

Last shot shows the progress so far, the milling nearly done then off to the lathe to size the bore. The little piece of brass shim is a very short homemade ruler so I could measure how deep the cut had gone without winding the cut off at all.

More tomorrow with a bit of luck