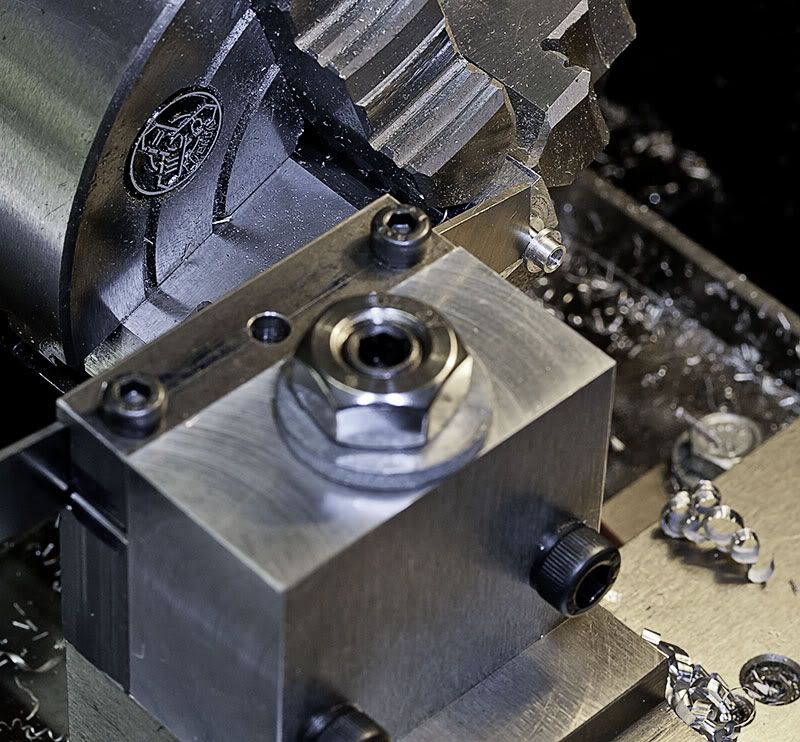

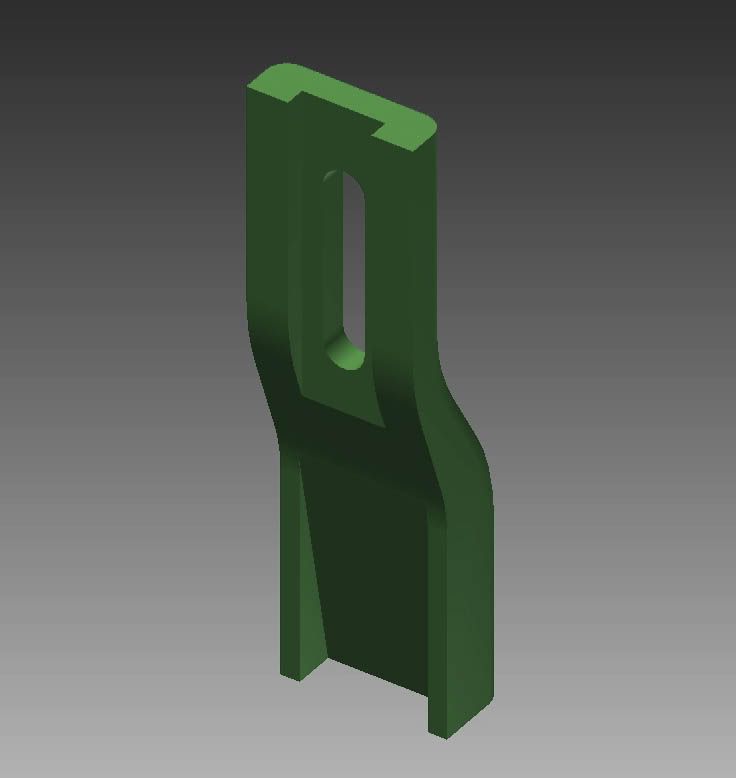

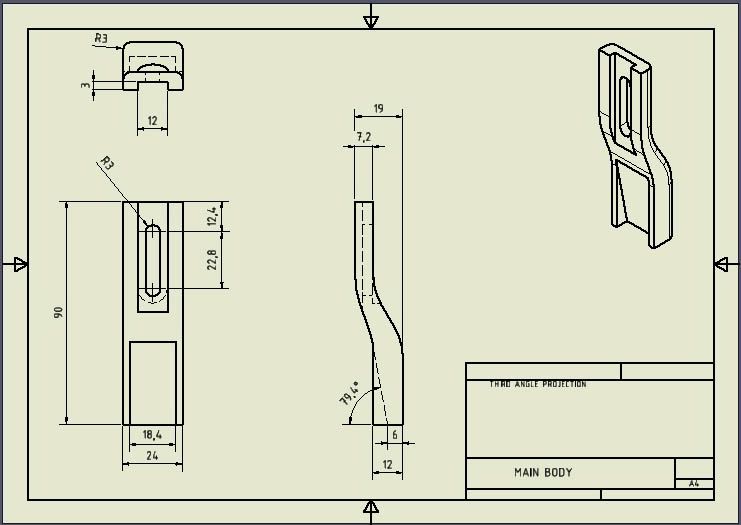

After many hours of modeling I have finaly started on my next project. The design is not set in stone but it should look a bit like the following. I am trying out inline pictures for the first time so hope it works!

http://www.flickr.com/photos/69203564@N05/7424843170/

The design consists of bits and pieces from many sources and a lot of changes made on the fly. Every change added more machining, this one will take a while to build.

Jan

OK, so the link doesn't work, all suggestions welcome.

http://www.flickr.com/photos/69203564@N05/7424843170/

The design consists of bits and pieces from many sources and a lot of changes made on the fly. Every change added more machining, this one will take a while to build.

Jan

OK, so the link doesn't work, all suggestions welcome.