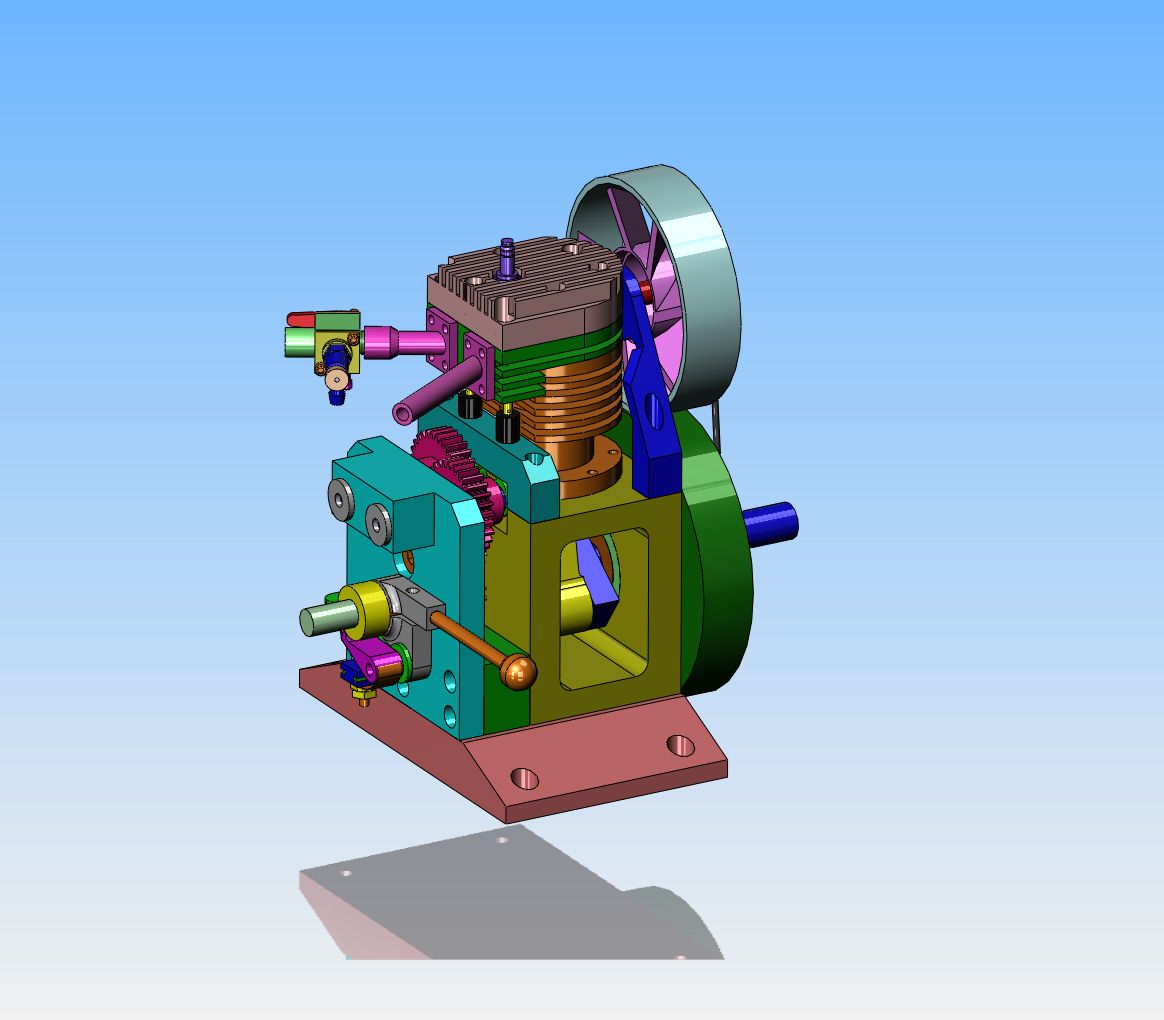

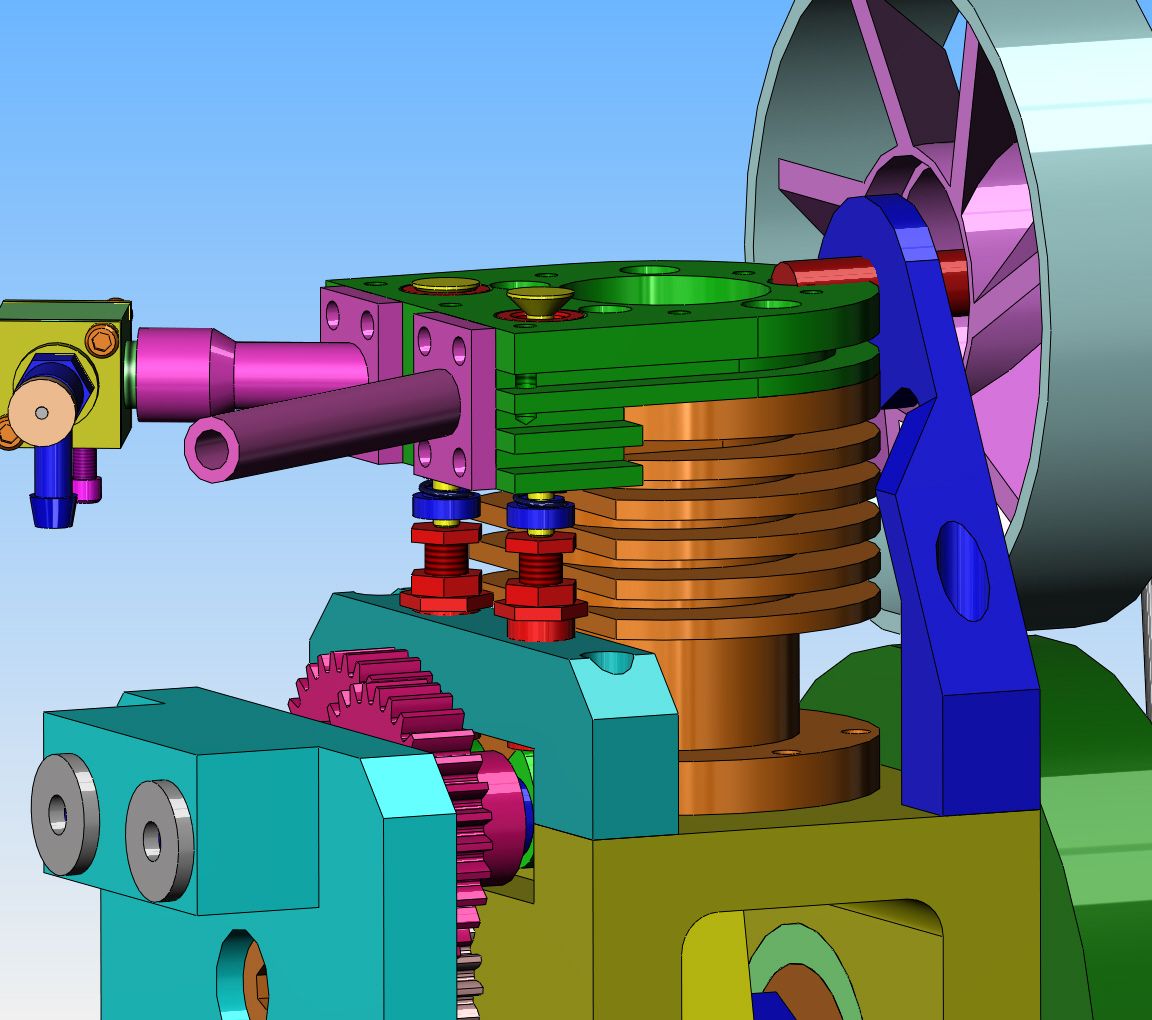

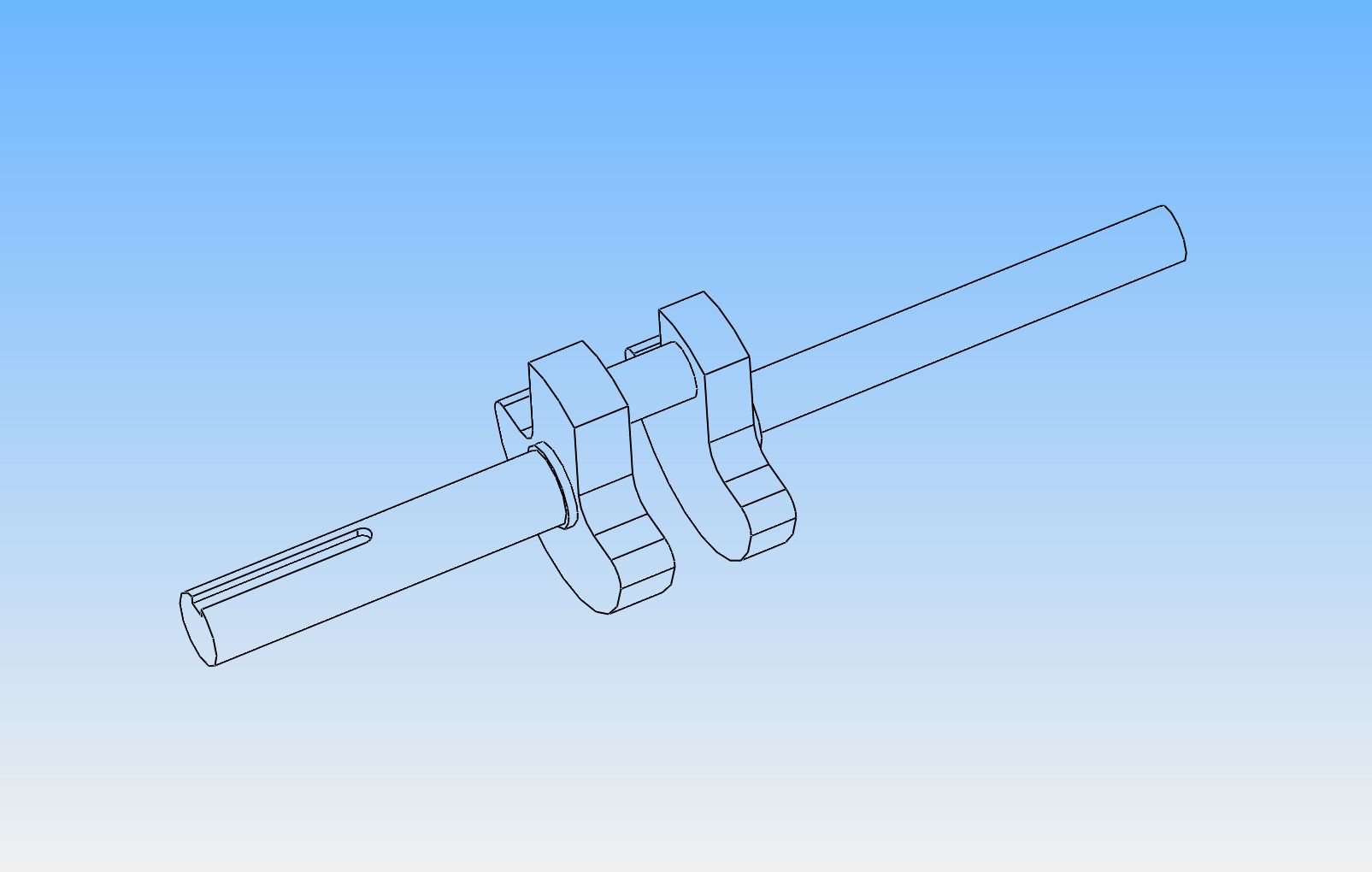

Well Sir!! I think that just about covers it!!! Oh, I've got to so something about a place for my started spud so I can use my variable speed drill as a starter, and probably add a few keyways and bolt holes, but I think the overall design is 99% done. everything on there I have built before on my previous 7 i.c. engines, except for perhaps the adjustable tappets----and that doesn't look like brain surgery. I think this will be a really neat project for a new engine this fall, and as usual I will be posting the engineering drawings fro anyone who wants to join in the fun. I guess my next step will be to make a list of all the bushings and bearings and go have a chat with my bearing supplier.---Brian