Hello all, I've been reading with interest the many ways of producing piston rings for model engines. My experience with making rings started in 1967, I was a spring chicken of about 18 years when I decided to build a model diesel four stroke from scratch. I had a few scribbles for plans, but mostly the plans or ideas were in my head. I lived on my Fathers farm and bought an old lathe as old as the hills, but it served its purpose. I had about two years experience working on a centre lathe at a local engineering firm. Finding scrap aluminium, cast iron from old machinery etc was no problem.

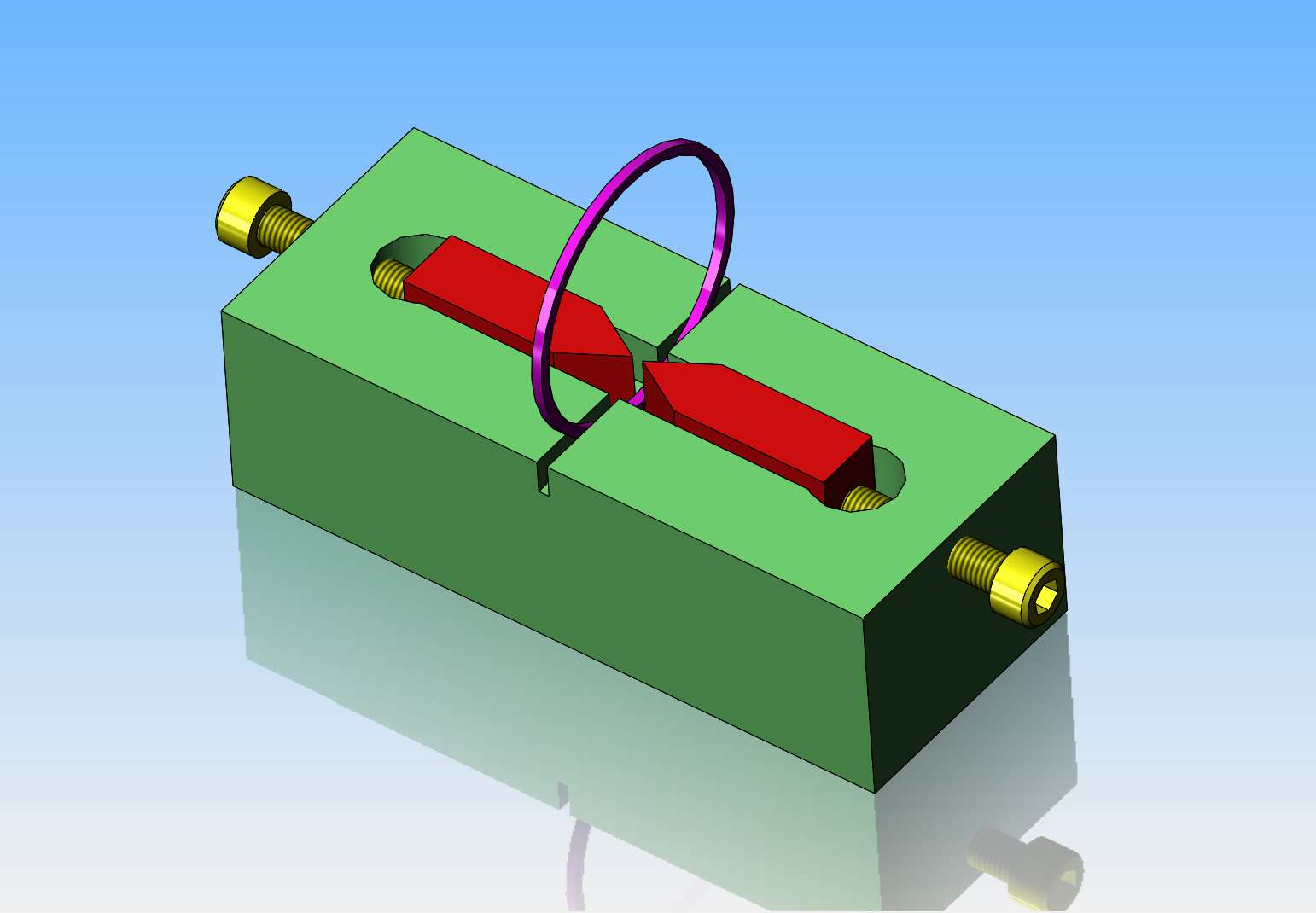

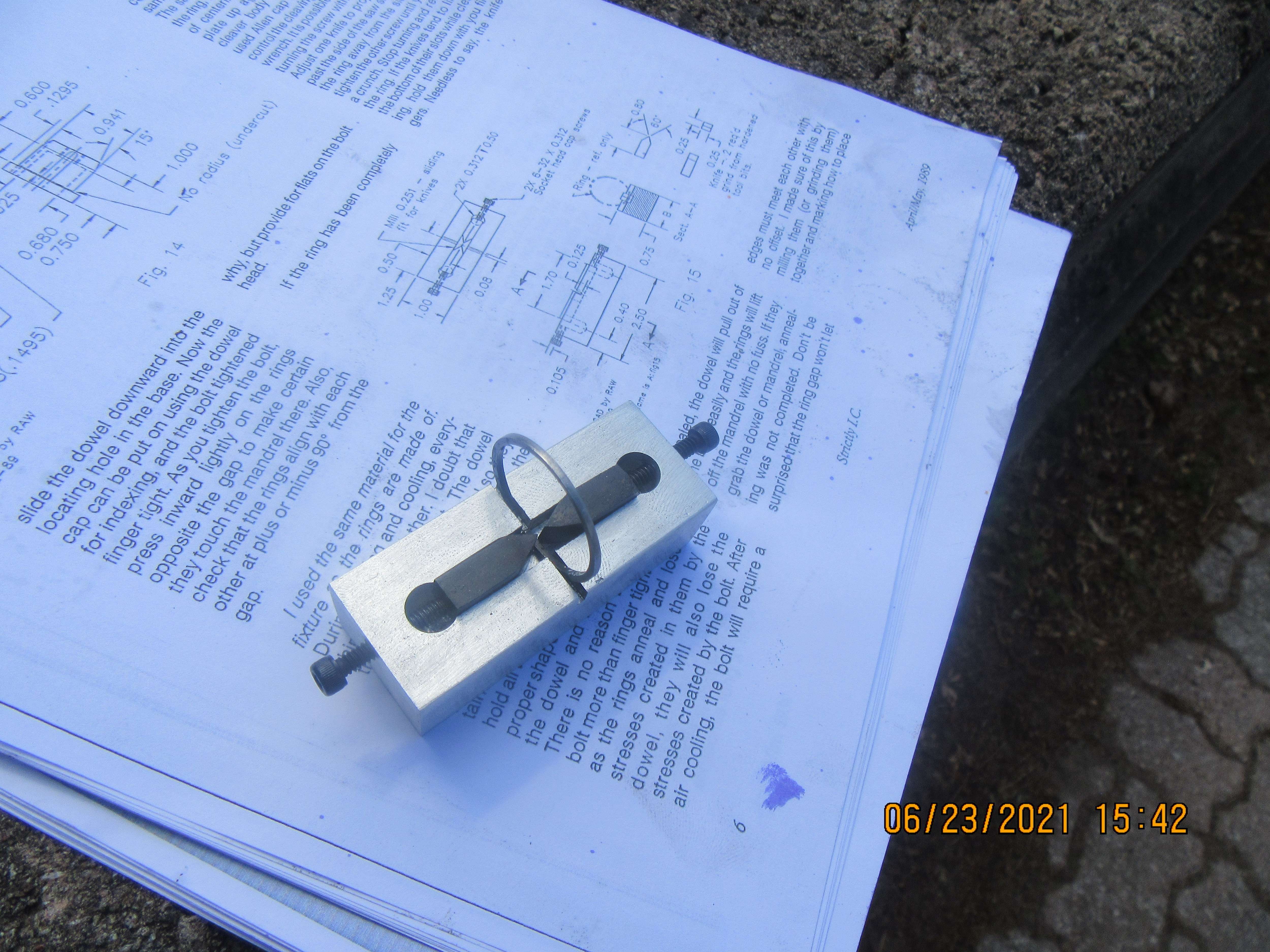

I melted the aluminium in my mothers rayburn "much to her annoyance" but she put up with me. I made everything except the ball races for the crankshaft and valve springs. I had it running on commercial diesel fuel blended with a small amount of model diesel fuel. It was stored for some 53 years until 2020. when I had renewed interest. Improving the fuel pump and injector and had it running again on 8 parts diesel to 1 part model diesel fuel. It would probably run on 100% diesel fuel when hot. I want to improve the fuel injection system more when I have a chance. I have a small recollection of making the piston rings. Made of cast iron, outside diameter turned to within a few thou of the required size. Cut them and bolted them to a mandrel with a centre screw to grip them and machined them to size with the required gaps preset to whatever size I came up with. Perhaps I should have posted this to general engine building. Hope you enjoy it.&

I melted the aluminium in my mothers rayburn "much to her annoyance" but she put up with me. I made everything except the ball races for the crankshaft and valve springs. I had it running on commercial diesel fuel blended with a small amount of model diesel fuel. It was stored for some 53 years until 2020. when I had renewed interest. Improving the fuel pump and injector and had it running again on 8 parts diesel to 1 part model diesel fuel. It would probably run on 100% diesel fuel when hot. I want to improve the fuel injection system more when I have a chance. I have a small recollection of making the piston rings. Made of cast iron, outside diameter turned to within a few thou of the required size. Cut them and bolted them to a mandrel with a centre screw to grip them and machined them to size with the required gaps preset to whatever size I came up with. Perhaps I should have posted this to general engine building. Hope you enjoy it.&

Last edited: