- Joined

- May 30, 2011

- Messages

- 135

- Reaction score

- 4

I couldn't find any 5 cylinder radial engine designs that were free, and also the lack of tools right now (4 jaw chuck for square bar cylinders) I decided to design my own from scratch. The proportions of my design just didnt look good, so i decided to try something out of the ordinary; an 8 cylinder radial engine.

There are some of these engines out there, but are not as common as the 3,5,6,7,9, or 15 cylinder radial engines, and that's what I like about it. Using some of my spare time at my university, and the machine shop that we've used for some of our classes, I can start making parts until the end of the semester, before i get my own mill.

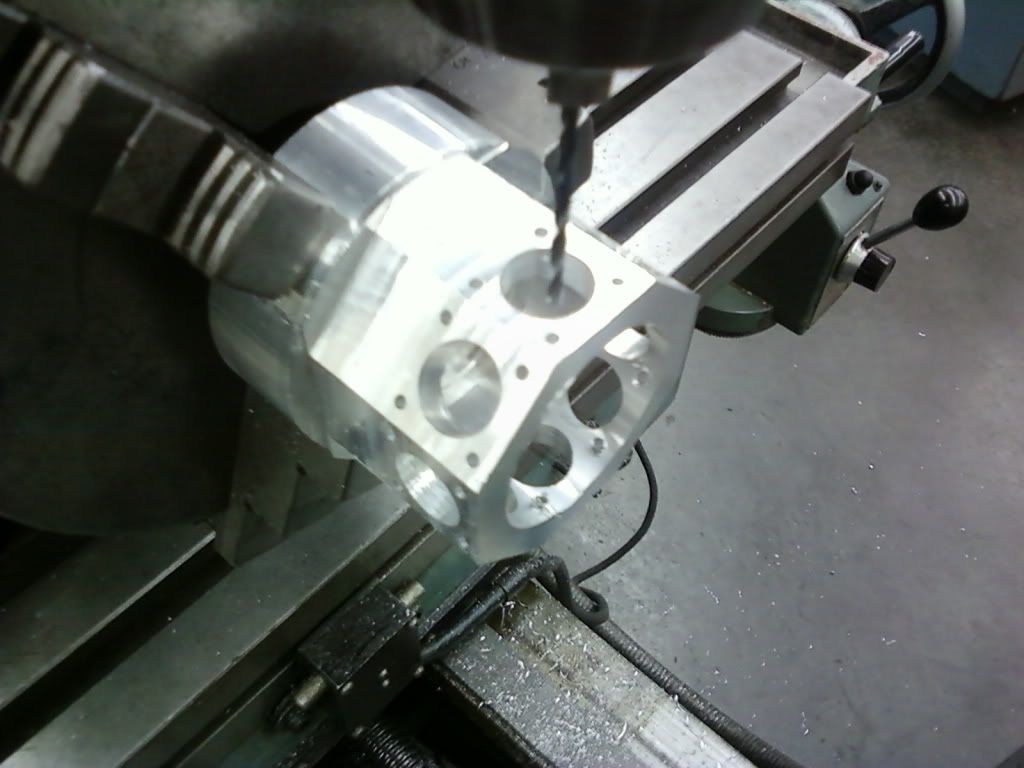

Pictures so far:

The crank case is made out of 6061 B221 Aluminum.

Mounted in a rotary table, using a 1" carbide insert face mill i started the task of milling the octagonal shape.

I swapped out the 1" carbide insert face mill with a 1 1/4" face mill; just to give me some more leeway when parting. First side complete.

Second side complete.

Third side complete.

Some more views.

Will finish on Tuesday.

Ian

There are some of these engines out there, but are not as common as the 3,5,6,7,9, or 15 cylinder radial engines, and that's what I like about it. Using some of my spare time at my university, and the machine shop that we've used for some of our classes, I can start making parts until the end of the semester, before i get my own mill.

Pictures so far:

The crank case is made out of 6061 B221 Aluminum.

Mounted in a rotary table, using a 1" carbide insert face mill i started the task of milling the octagonal shape.

I swapped out the 1" carbide insert face mill with a 1 1/4" face mill; just to give me some more leeway when parting. First side complete.

Second side complete.

Third side complete.

Some more views.

Will finish on Tuesday.

Ian