mikemott

Well-Known Member

- Joined

- Oct 24, 2014

- Messages

- 53

- Reaction score

- 67

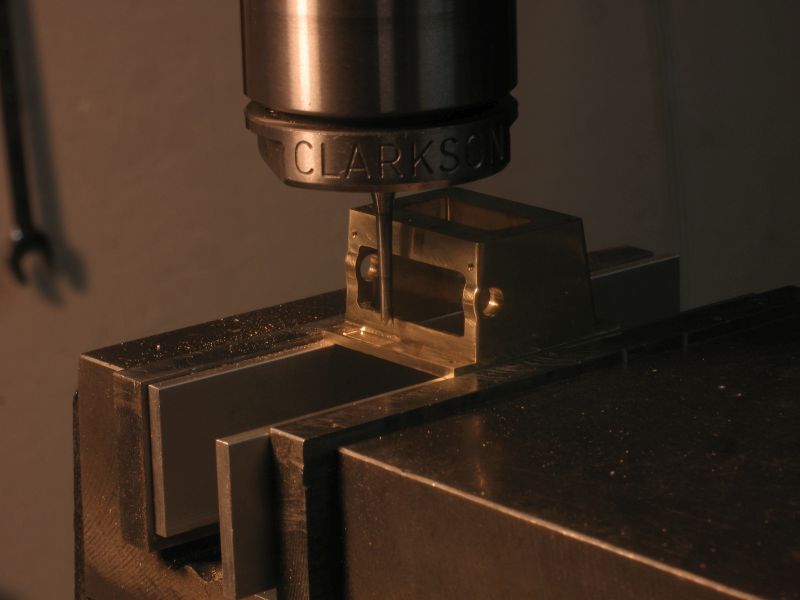

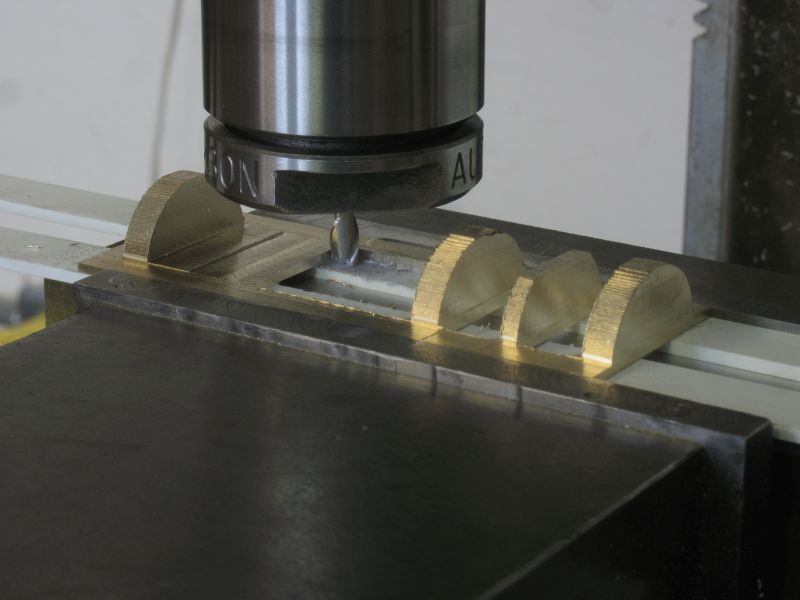

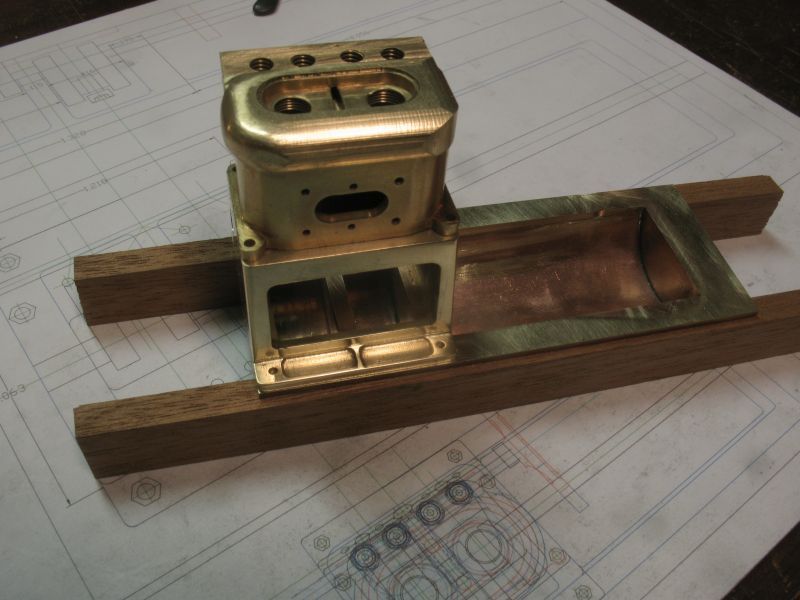

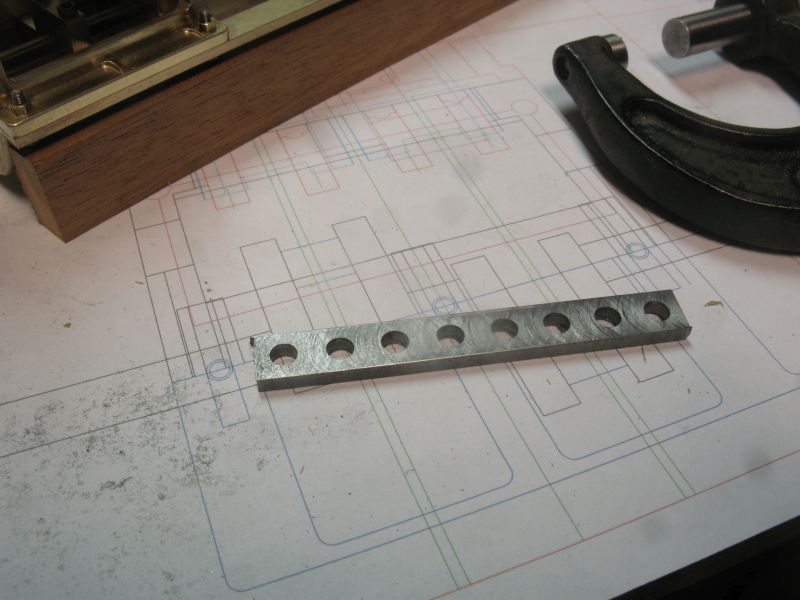

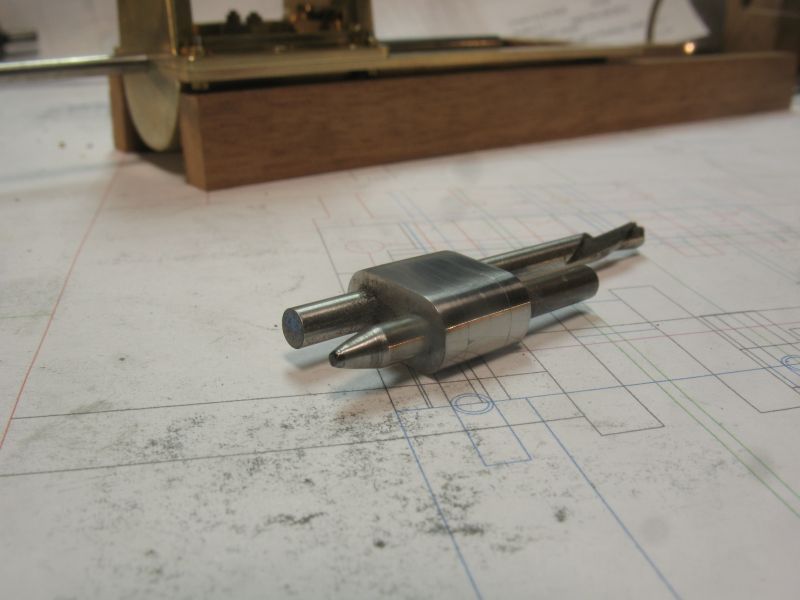

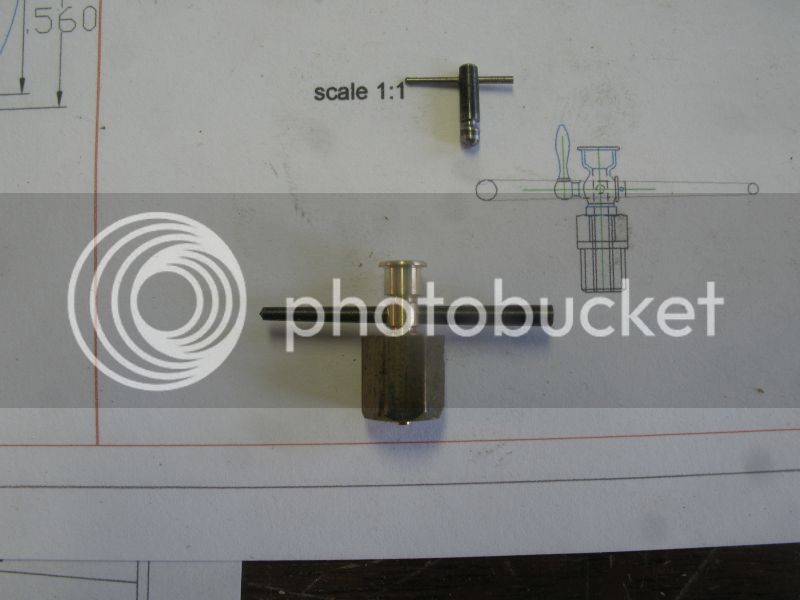

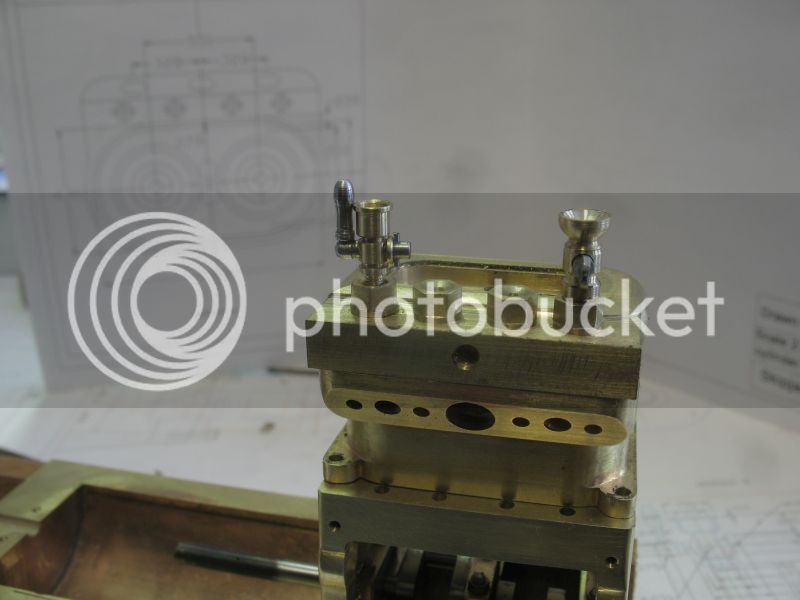

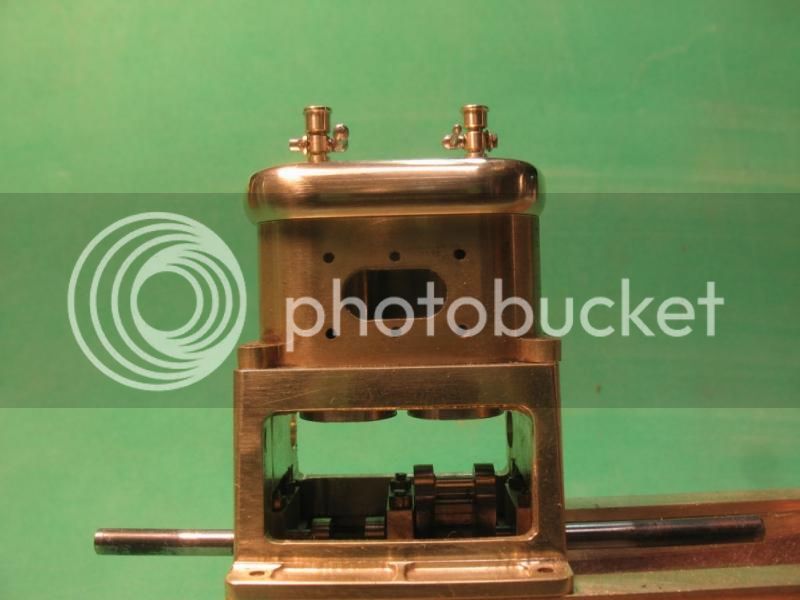

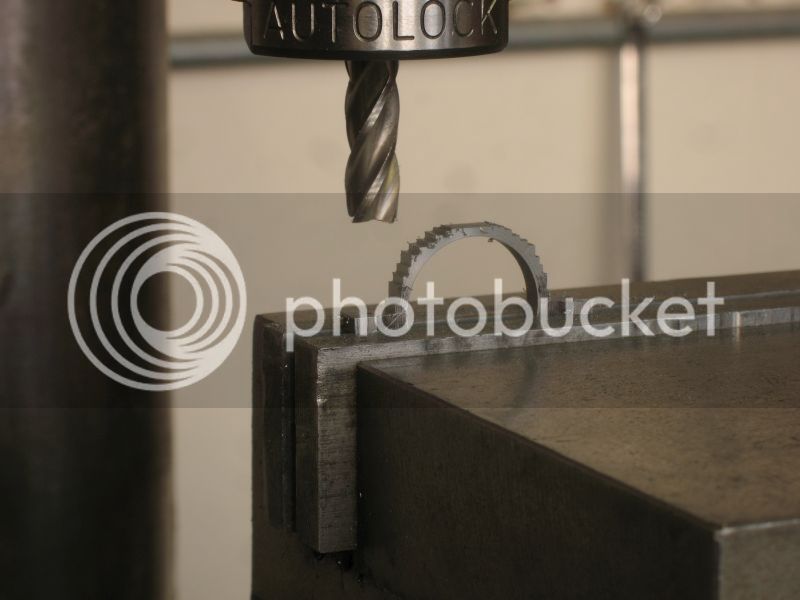

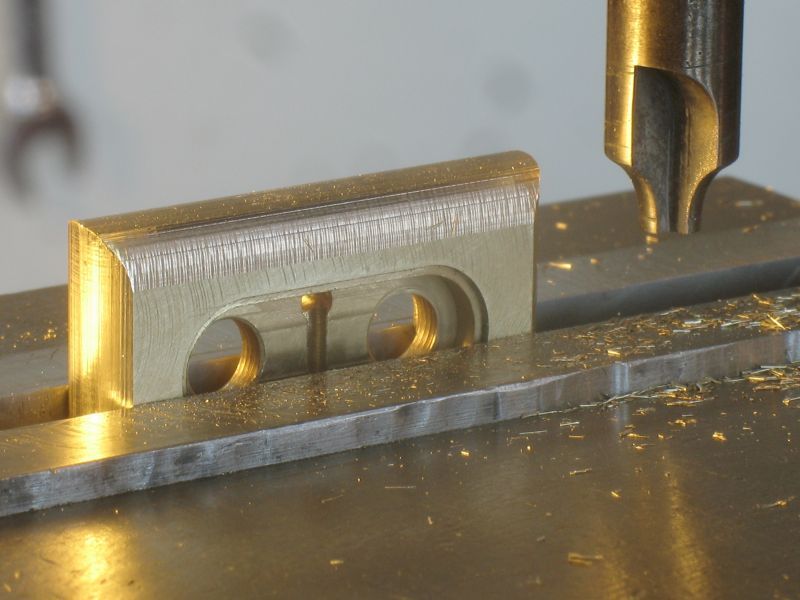

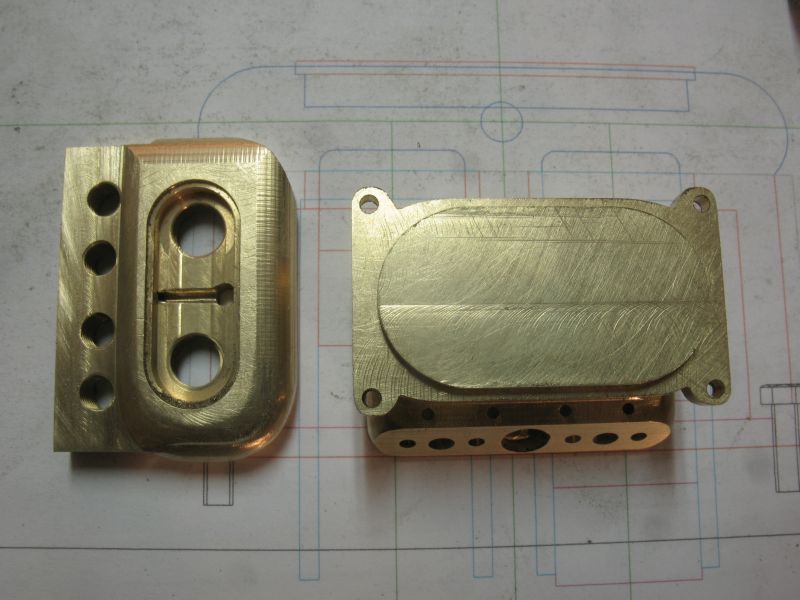

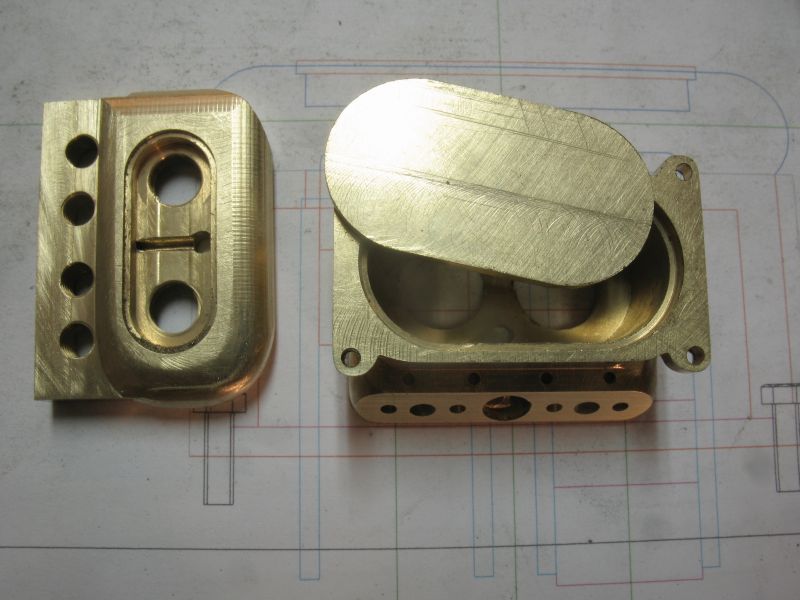

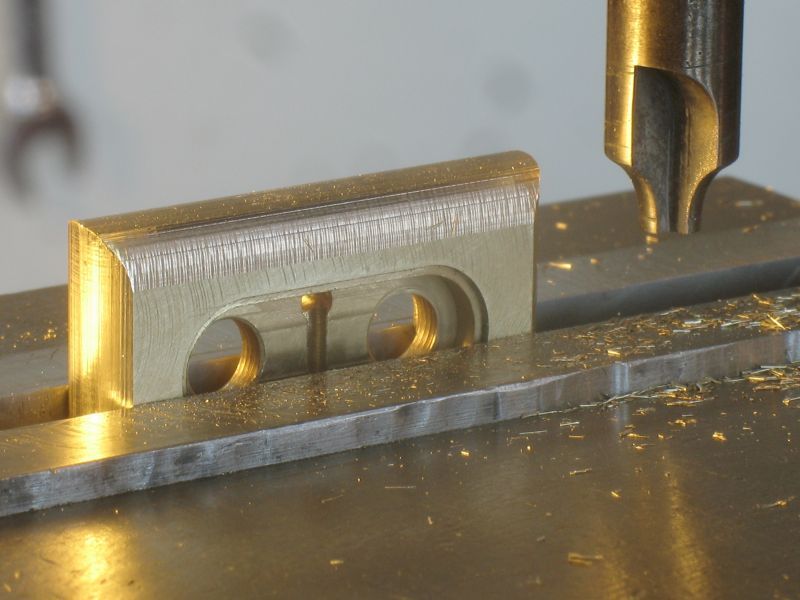

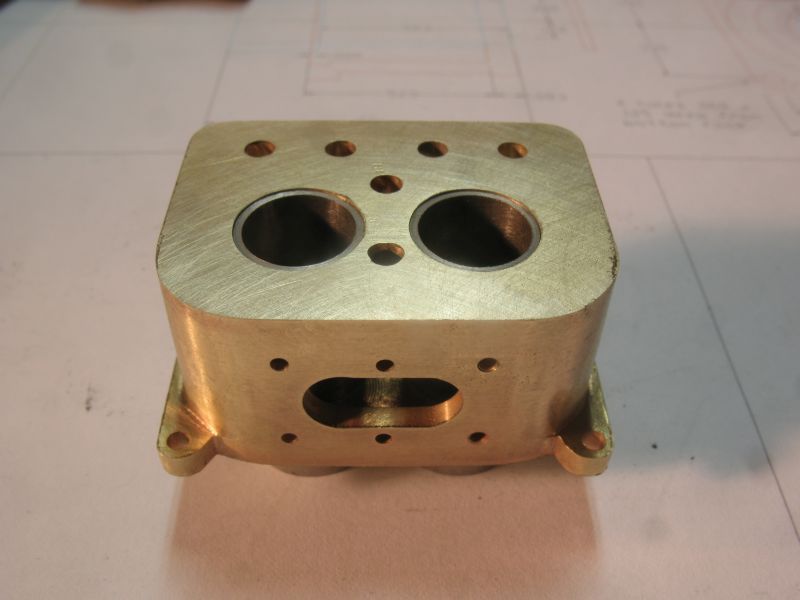

Further progress on the cylinder head the curved top required a new cutter

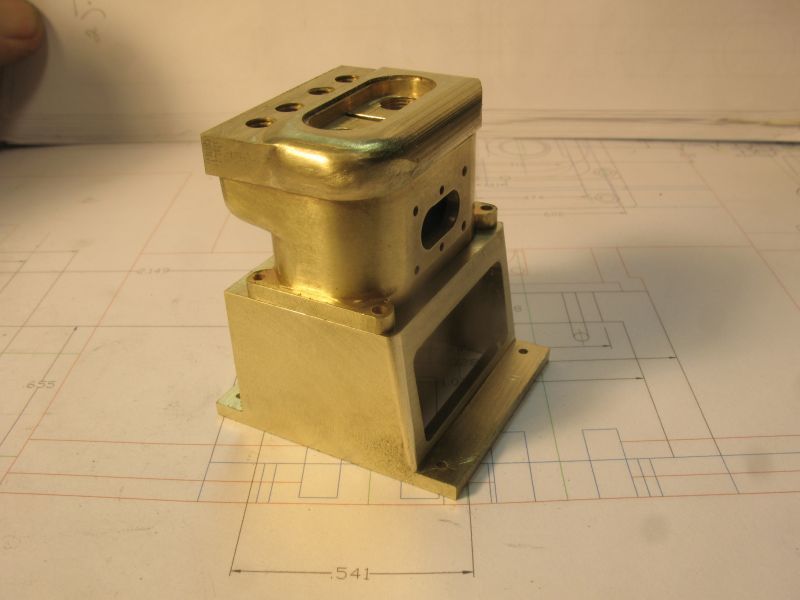

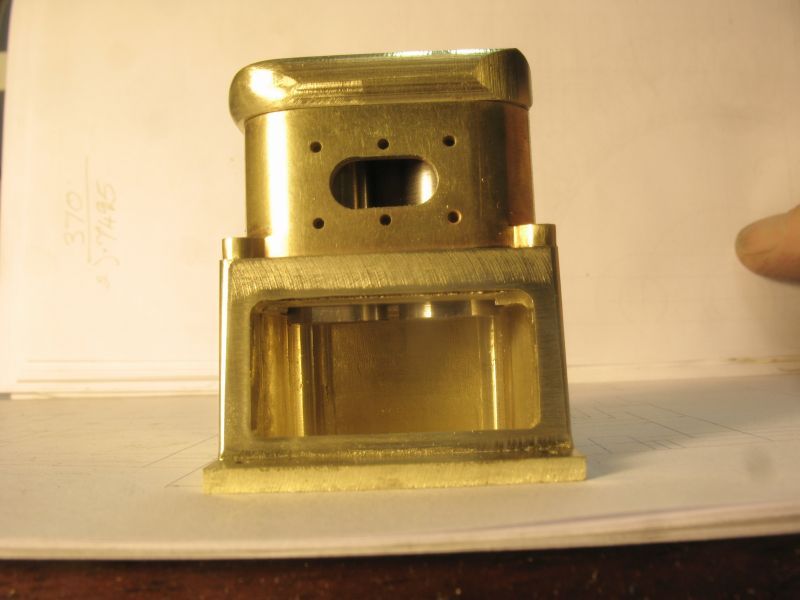

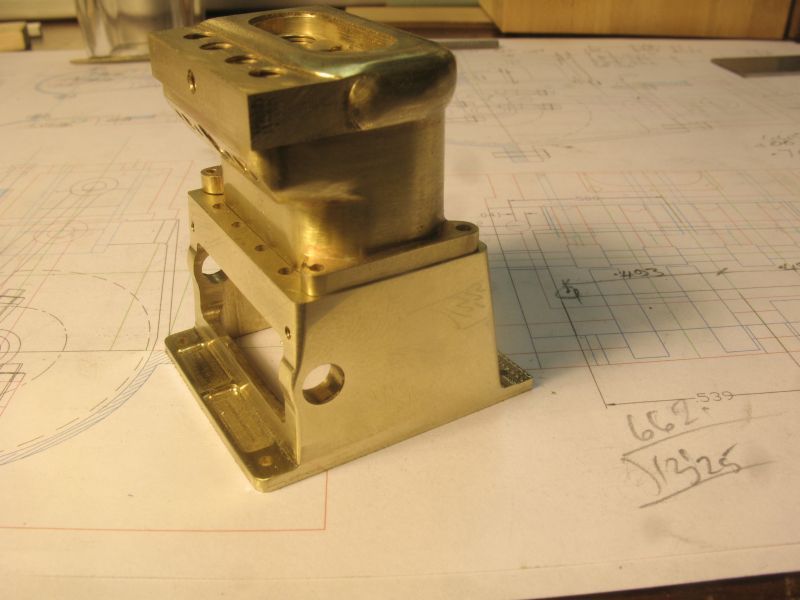

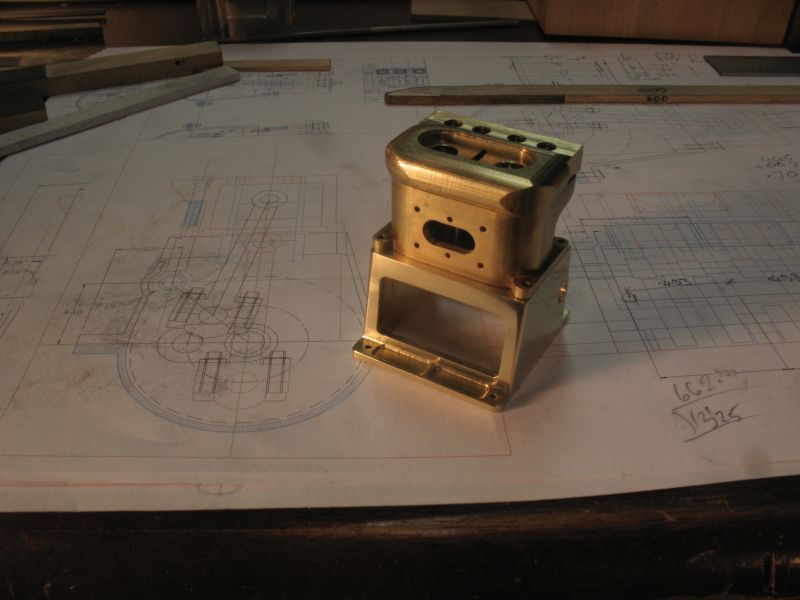

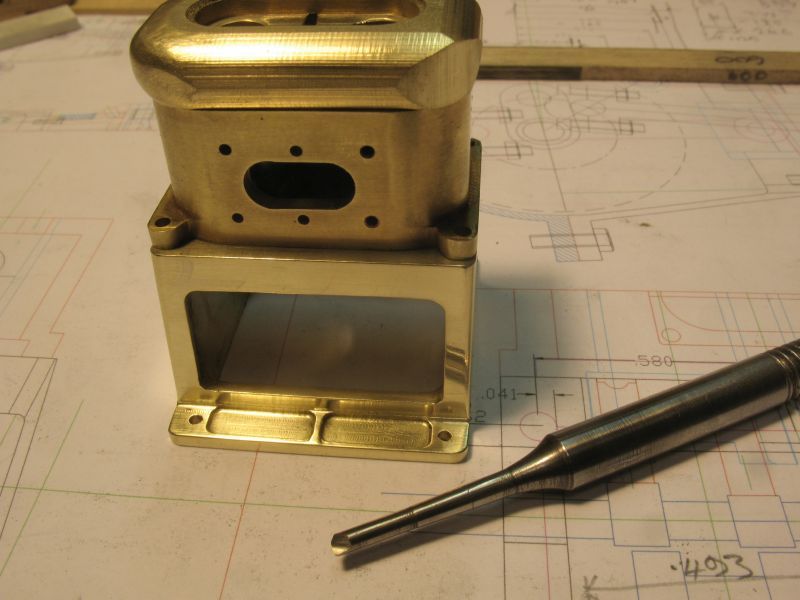

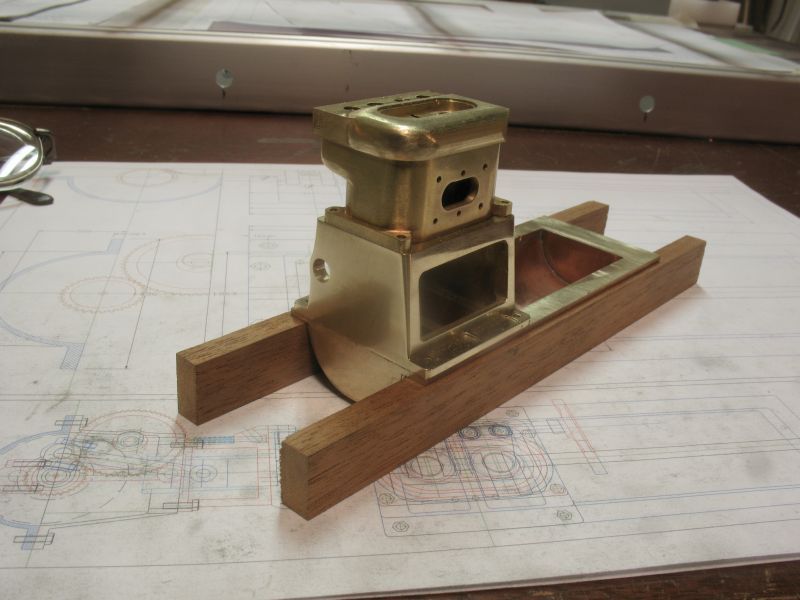

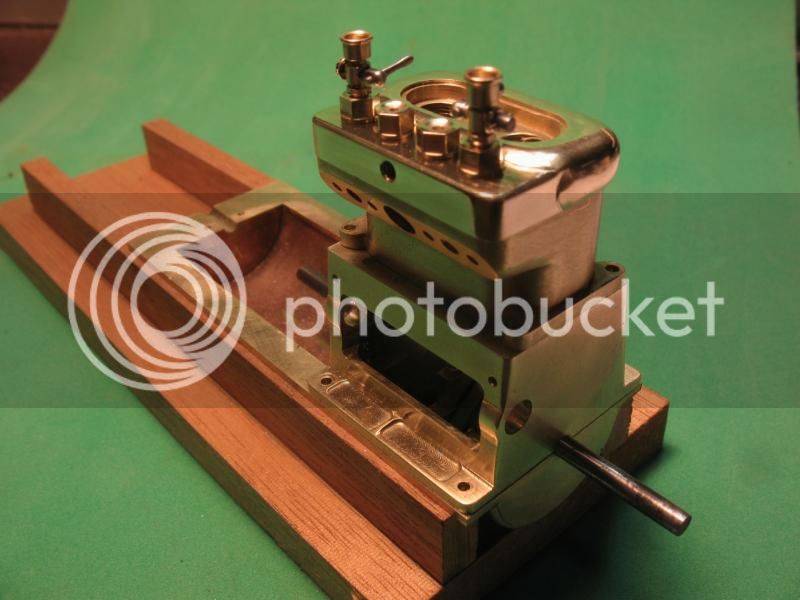

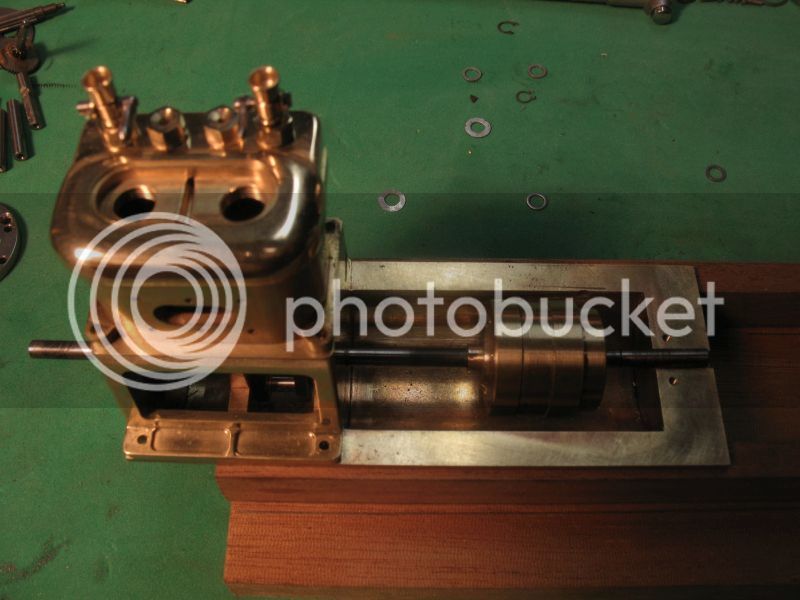

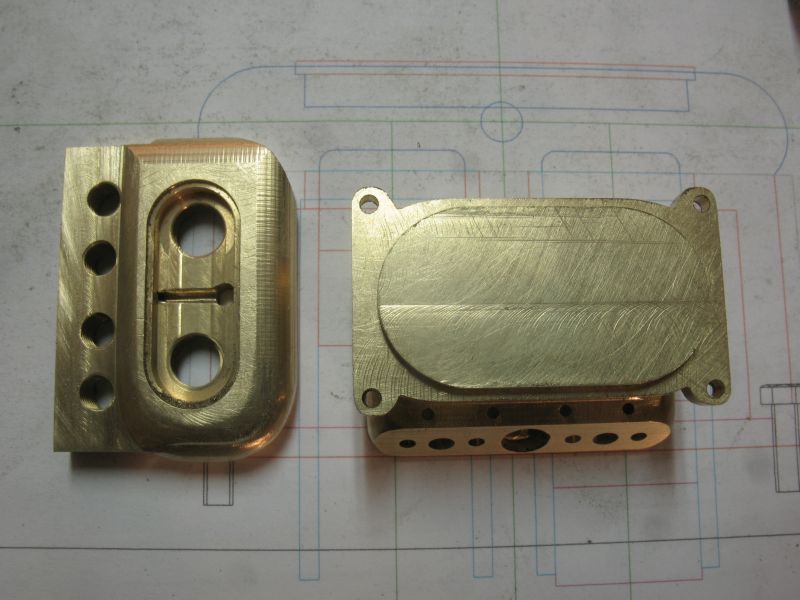

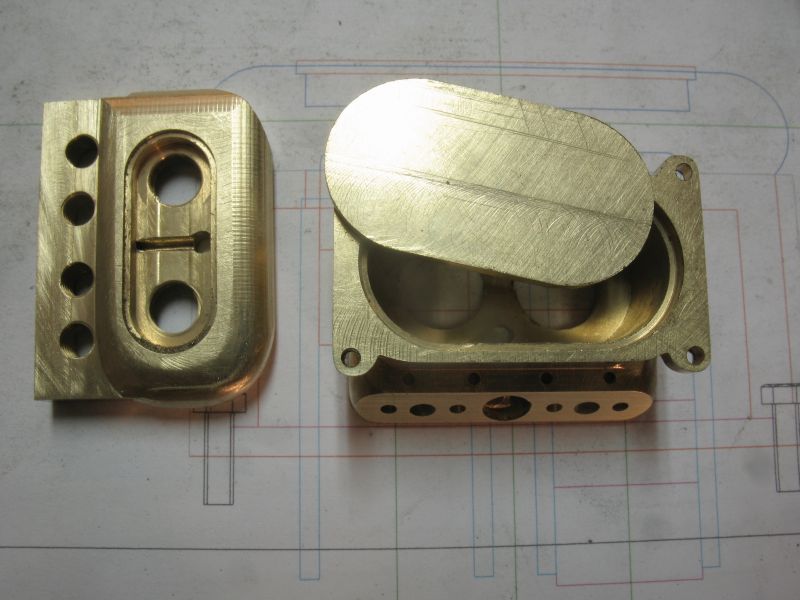

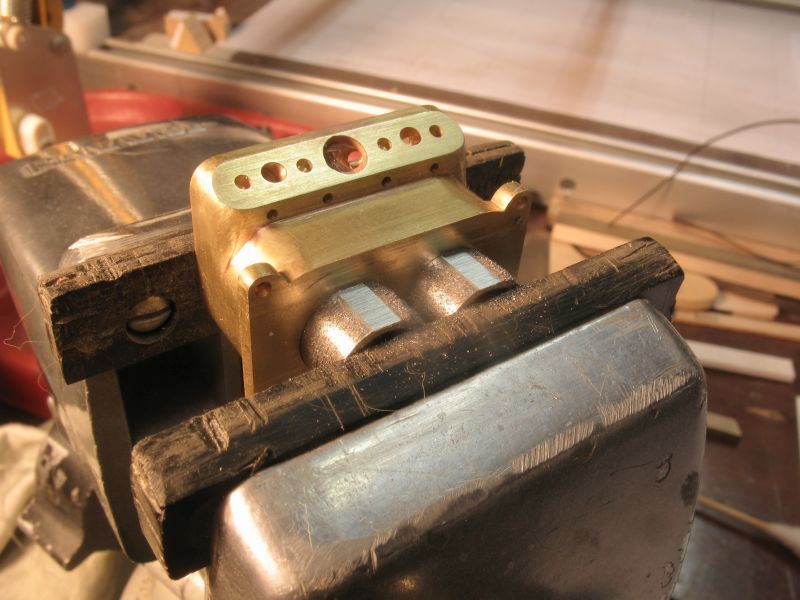

Some of the shaping to the top has been started with files, and the bottom plate is fitted to the water jacket.

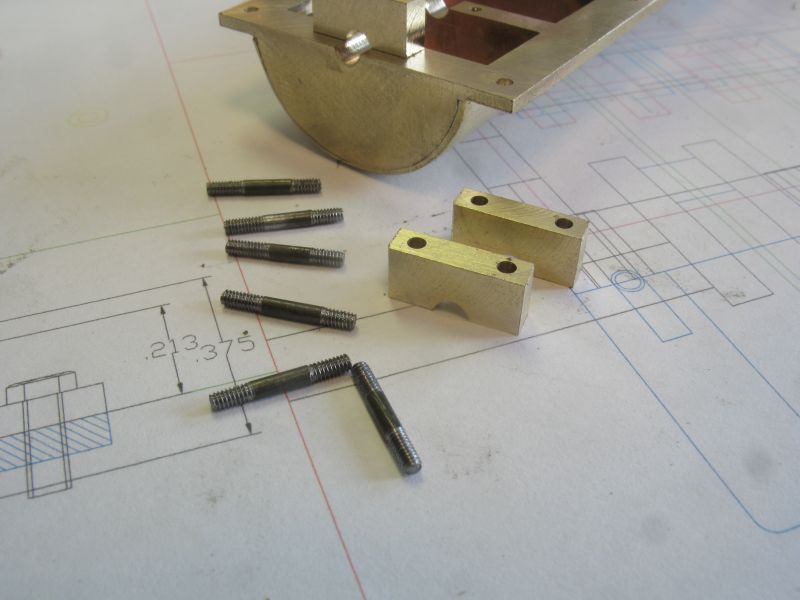

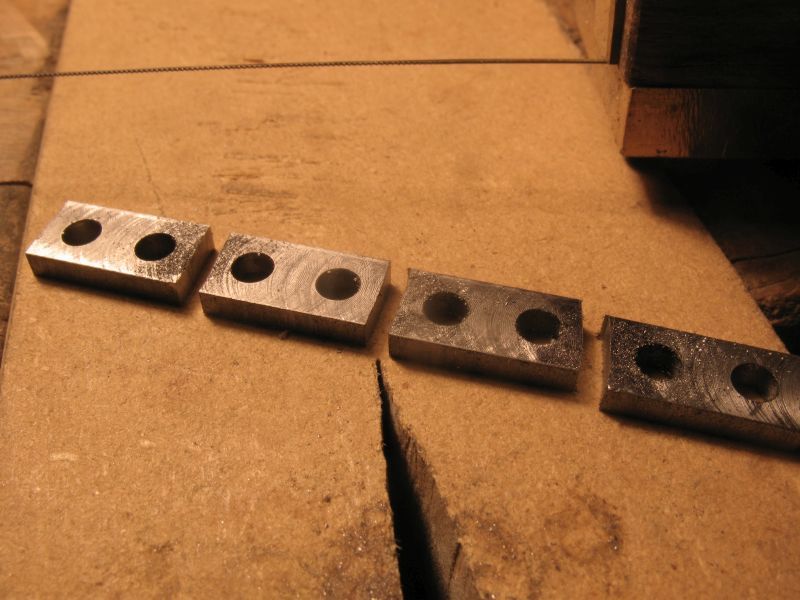

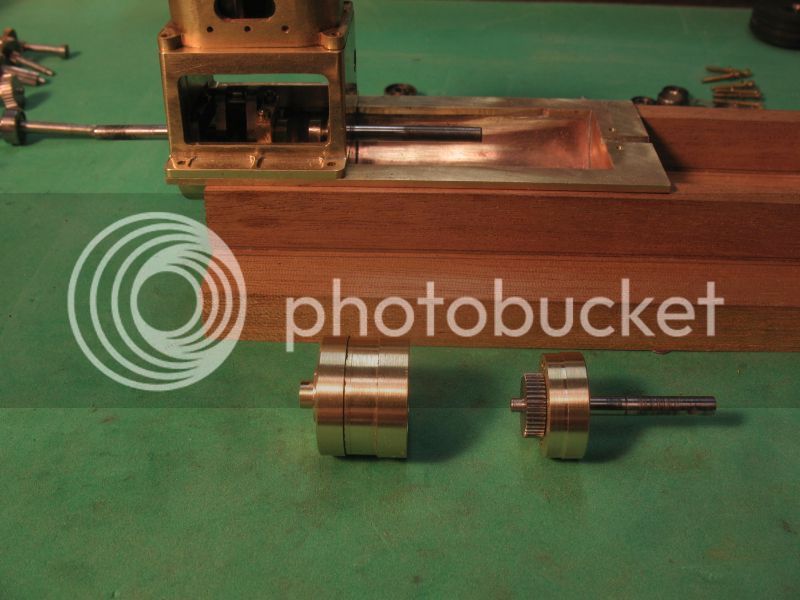

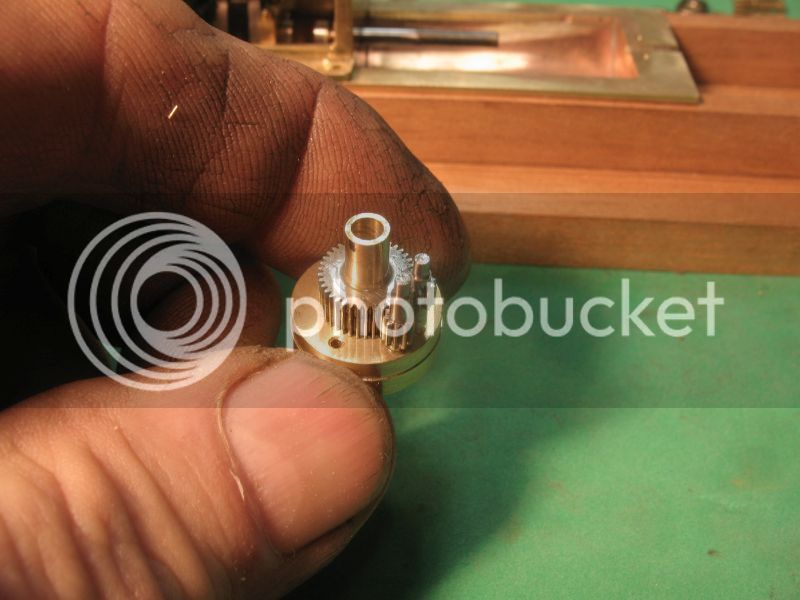

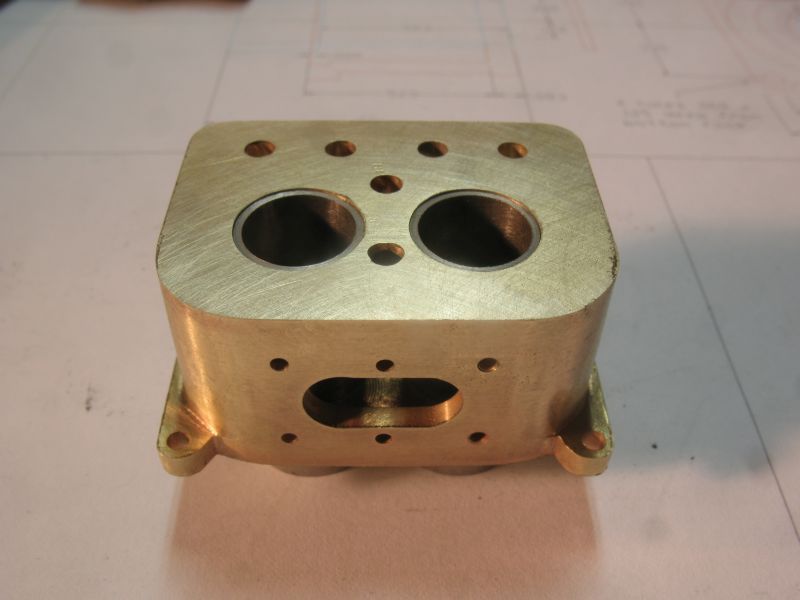

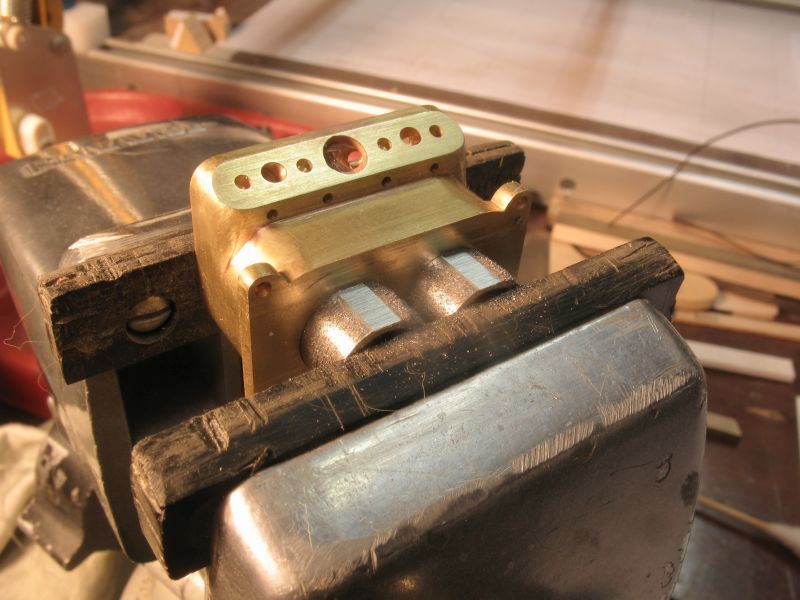

The liners are reamed and a press fit.

The bottom of the liners are flattened on both sides to ensure that they stay in place, they will slide fit into the top of the crankcase

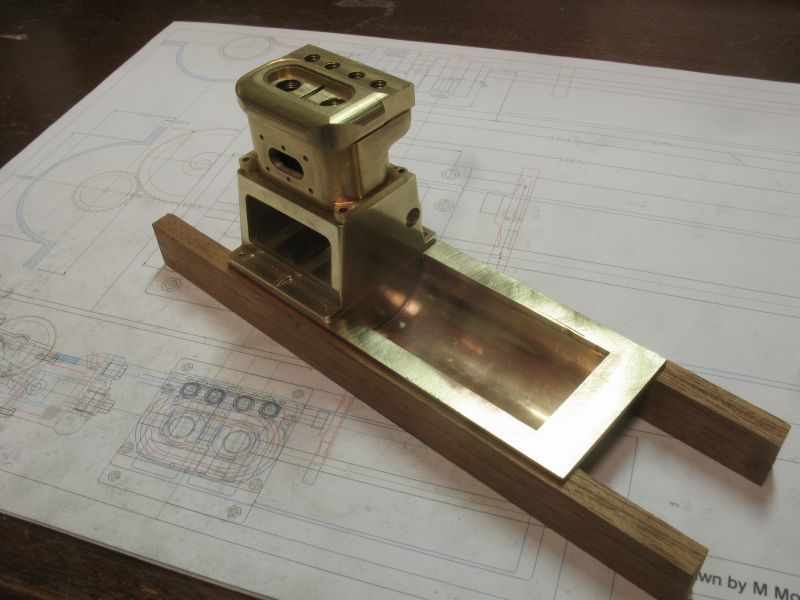

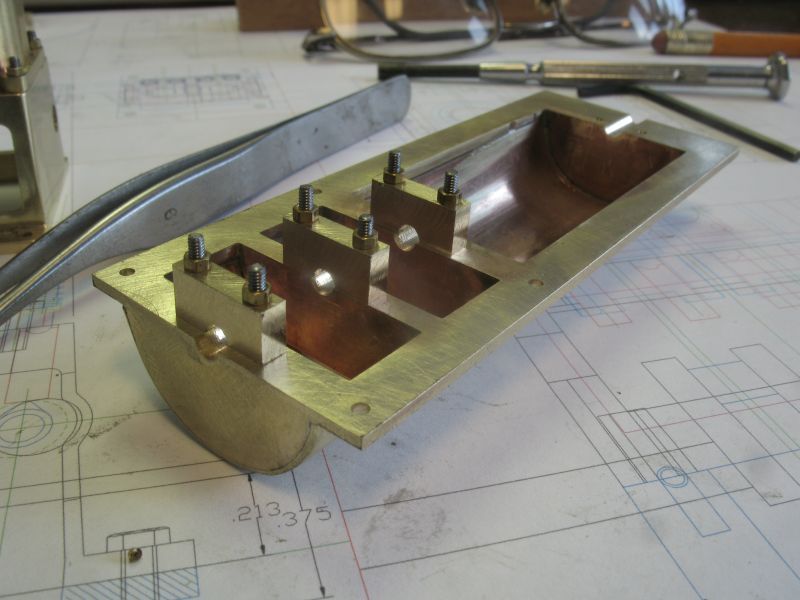

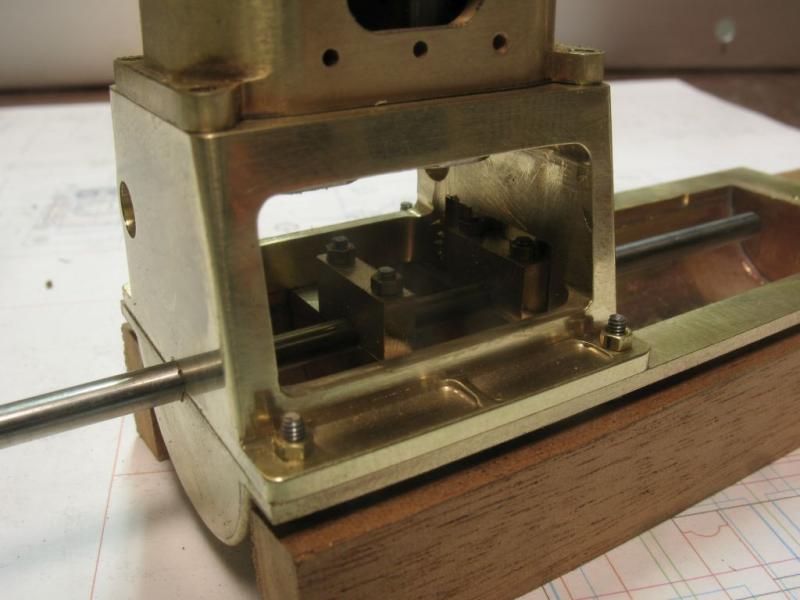

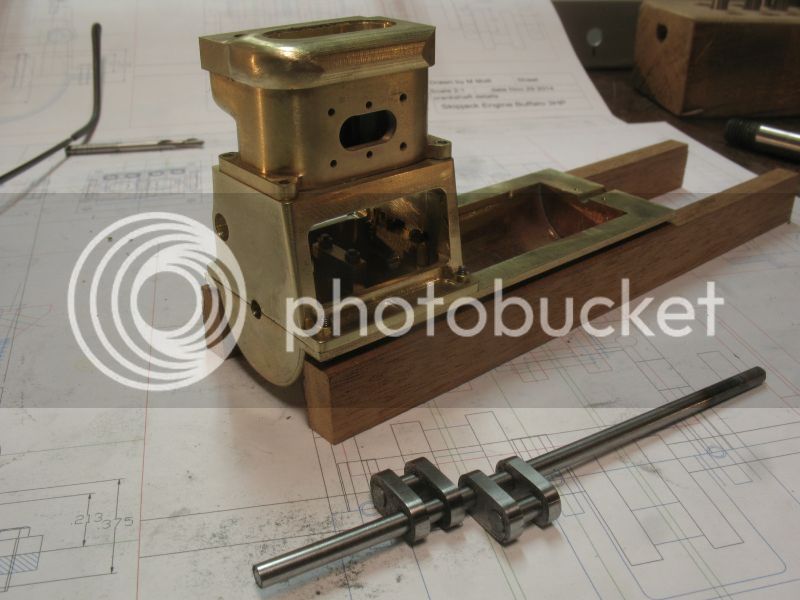

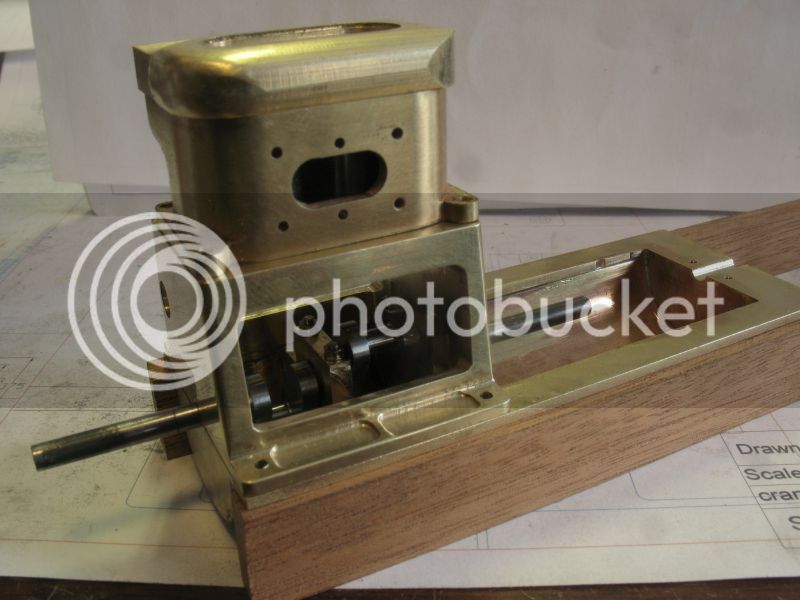

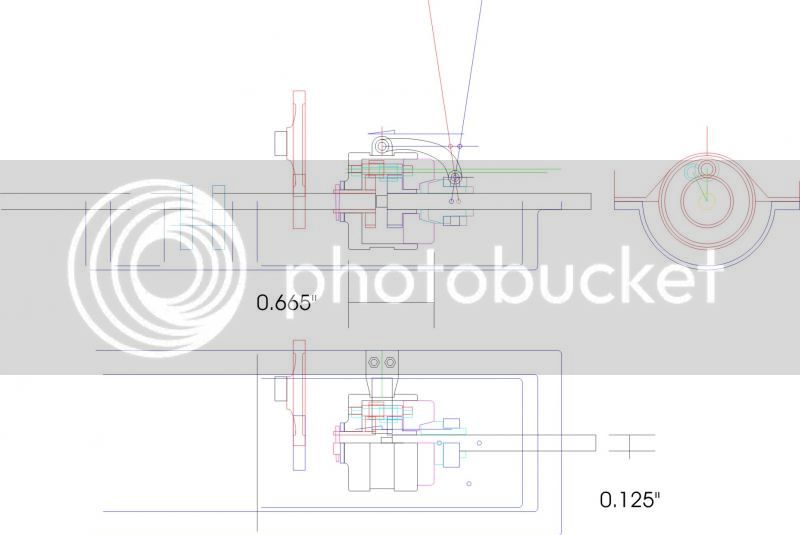

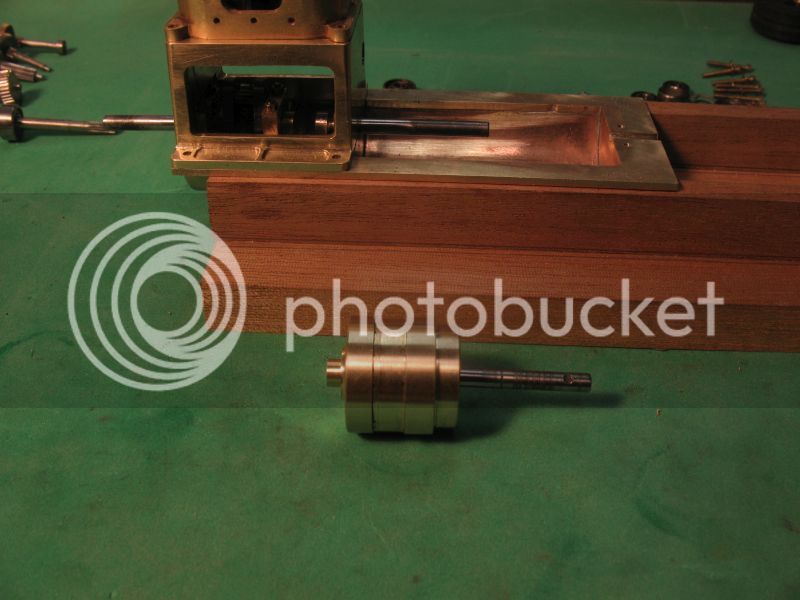

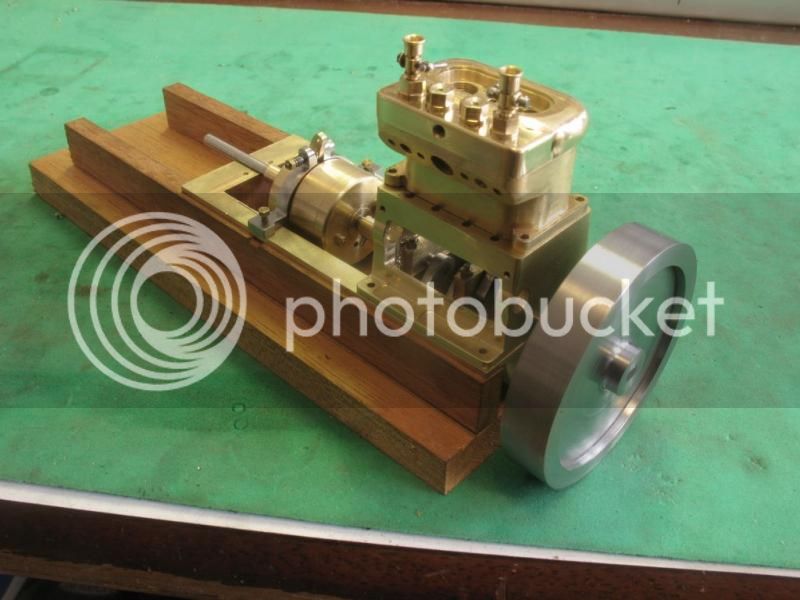

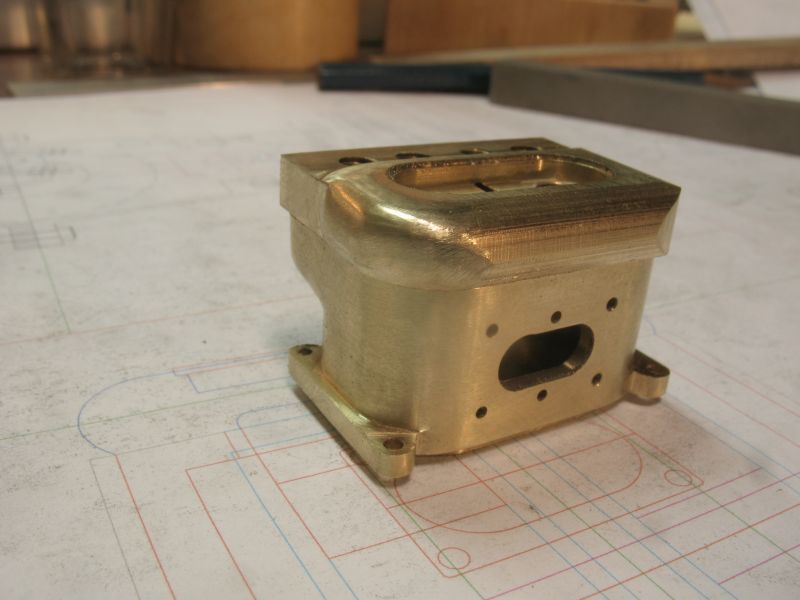

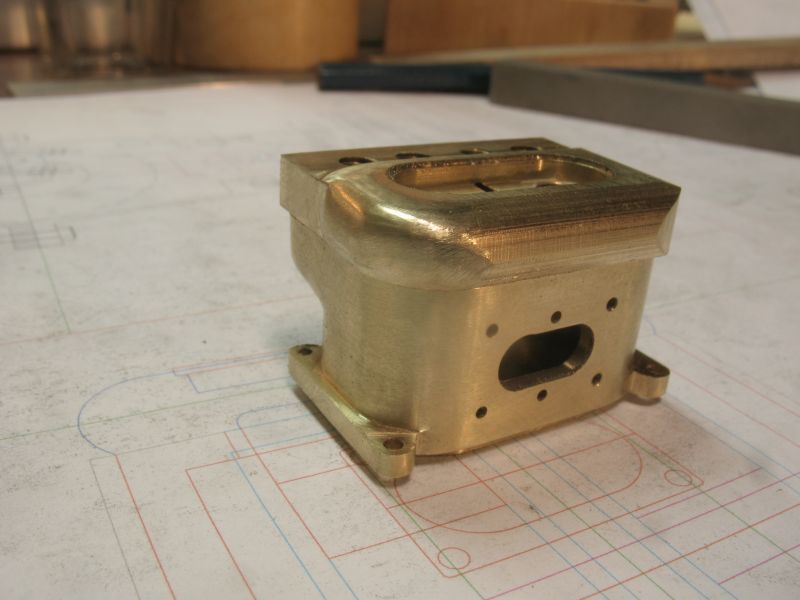

The start on the crankcase.

Michael

Some of the shaping to the top has been started with files, and the bottom plate is fitted to the water jacket.

The liners are reamed and a press fit.

The bottom of the liners are flattened on both sides to ensure that they stay in place, they will slide fit into the top of the crankcase

The start on the crankcase.

Michael