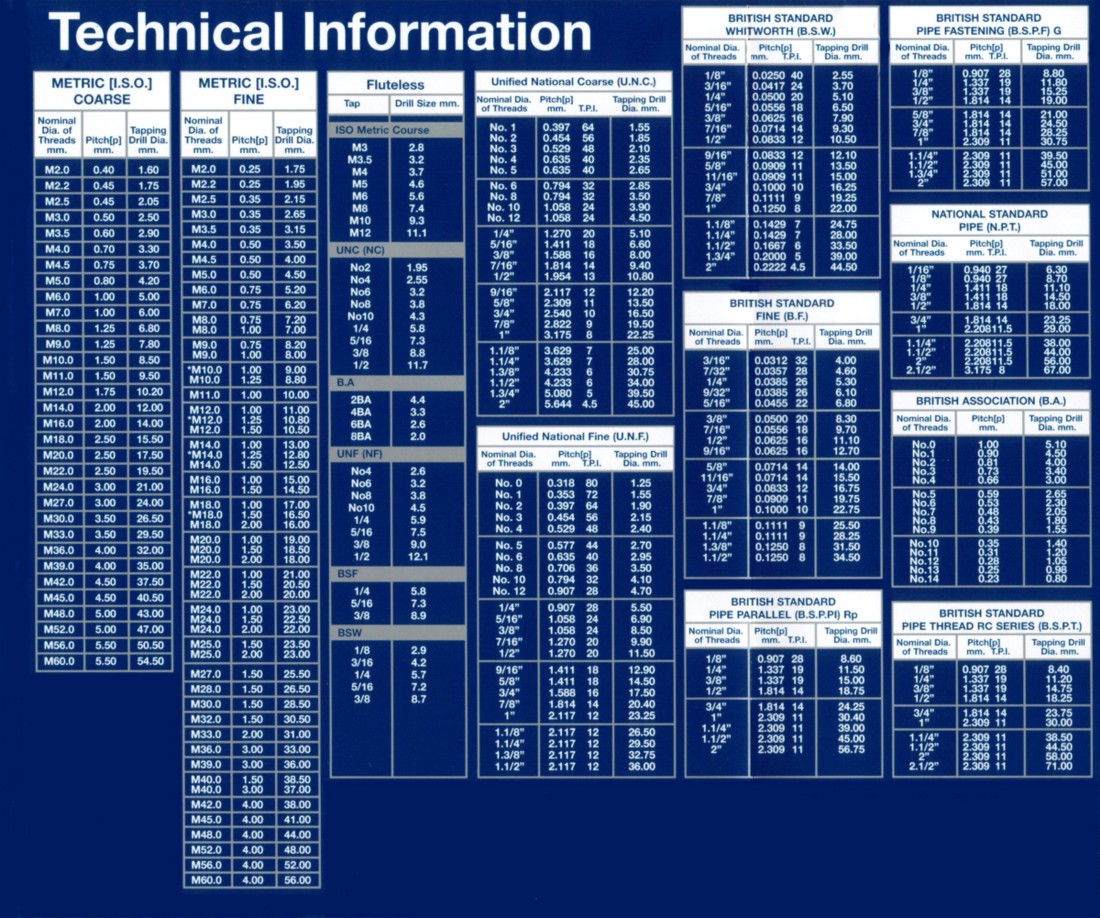

Having an actual conversion chart would be the quickest method for metric - imperial or the reverse. But it's easy enough if you've got a tap drill chart. Just find the tap drill size in lets say metric, convert that to it's imperial decimal equivalent, and then find the closest recommended tap drill for an imperial sized thread, and there's your size and thread conversion. Whitworth, BA etc could be done the same. No it won't be exact, but it would be close enough in most cases. In some ways M.E. threads are also used for aesthetic purposes since the much finer threads look closer to the items reduced scale size versus full size. So for that reason there's no exact conversion other than our 4-40 tpi and 8-32 would match well enough for the 40 and 32 M.E. threads. And I'd assume the same could be true for a few metric threads that might be close.

Whitworth and the M.E. threads also have a 55 degree thread flank. Imo 55 or 60 degrees and the various root and crest shapes such as what the BA threads have would probably make no difference for what most of us would be doing. There's also lot's of 40 tpi taps and dies available with that 60 degree flank angle that are listed as special thread in most of the larger tool supplier catalogs. While considered non standard, a lot of those same suppliers have them on the shelf for not much more than what the usual taps and dies are priced at. There a handy source when building something like your own boring head and might want that much larger diameter 40 tpi for measurement and adjustment purposes on the slide. Although I believe the M.E. series does go up to 1/2" x 40 tpi. But I've also seen non standard and large diameter 60 or even up to 80 tpi listed. Since I don't usually use metric, I don't know if the same might be true for non standard mm pitches.