Hi Brian,

I would consider other constraints, such as the location of a cooling fan - and which way the hot air will blow? You don't want to boil petrol (about 100deg.F?) - or even just heat it, as a temperature rise from cold to hot could affect the mixture significantly. It has a large coefficient of expansion...

Equally, it does not want to become an earth for any sparks should there be any failure at the coils...?

What is your experience of your running times? Fuel capacity can be related to that? So if you do a few 5 to 10 minute runs, never more than 15 mins, then a 2 hour tank is not necessary. a 20 to 30 minute tank should suffice.

I have a Motorcycle that only does 100 miles on a tank-full. Around town and commuting 60 miles a week meant I only filled it weekly... so the small tank wasn't a problem. But maybe a smaller diameter and longer tank will give you options? I appreciate a larger flatter tank will give less variation of the petrol Head to the carburettor, than will a small and tall tank. A clear end is a very good idea. Use a petrol resistant gasket material. Glass microscope slides, or old GLASS spectacle lens can be cut/ground to function for that purpose. Or you can make a level gauge - like on a steam boiler? - That could be fun? But I am not sure how well the level can be seen with engine running vibration causing petrol to appear to "fizz"?

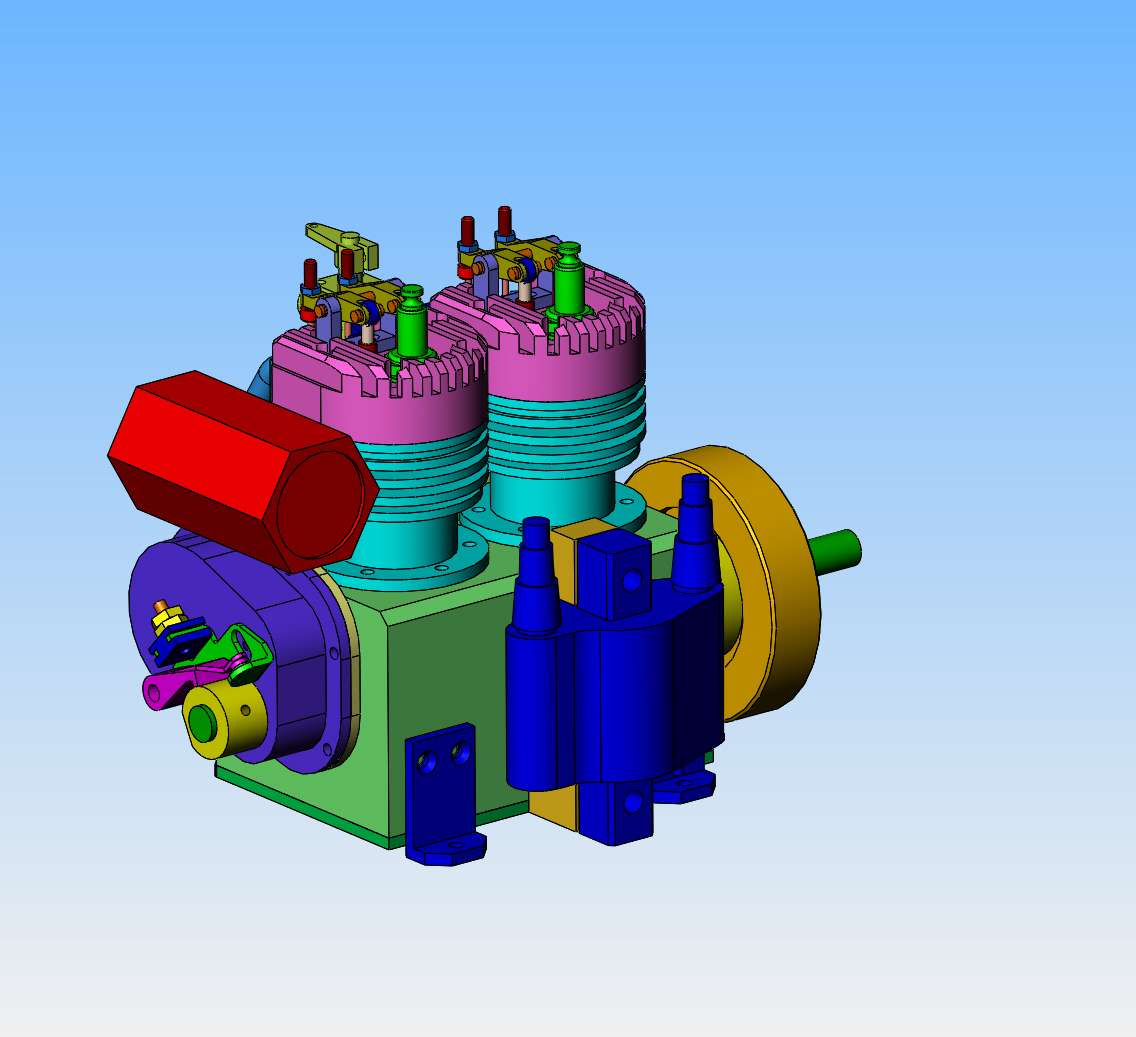

Love to see your photos. Excellent work.

K2