a41capt

Well-Known Member

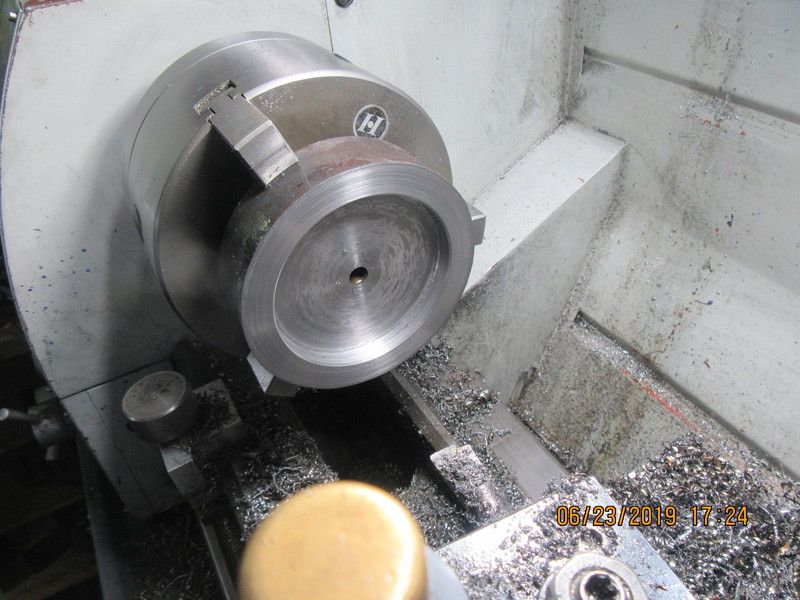

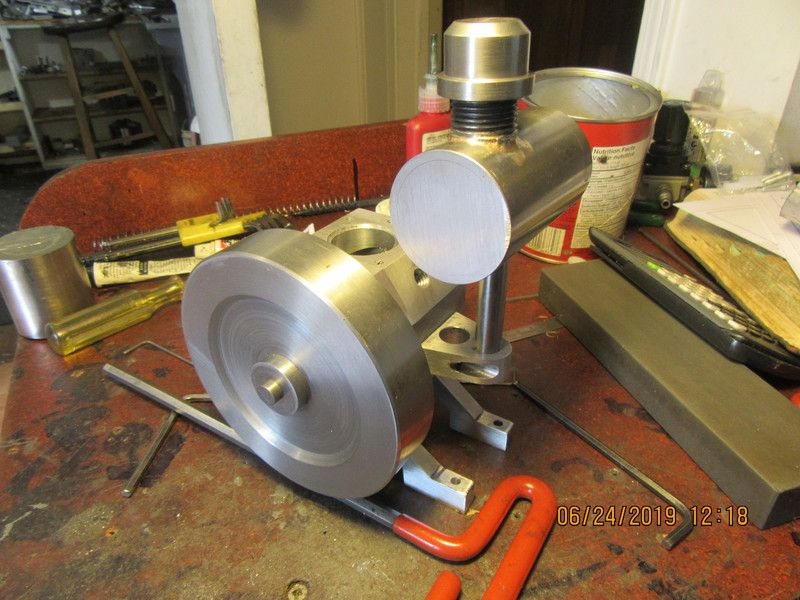

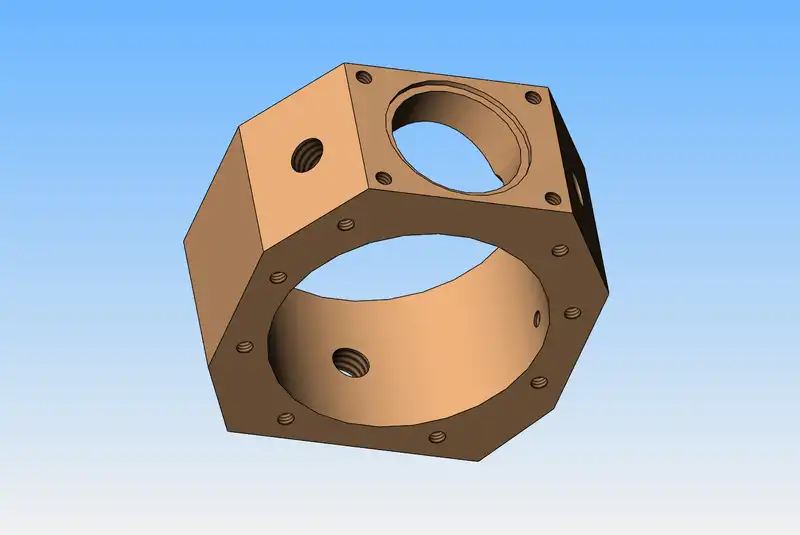

At the very last moment, I decided to put an o-ring groove in the top of the main body. This engine will have a "wet" crankcase, and it's either go with an o-ring or put a gasket between the main body and the cylinder to prevent oil leaks.

As soon as I saw the closed crankcase design, I wondered if you were going to build a wet crankcase with a con rod “splasher” for lubrication.

Looking good Brian, another cool build!!!

John W