- Joined

- Dec 9, 2015

- Messages

- 327

- Reaction score

- 349

Gday all

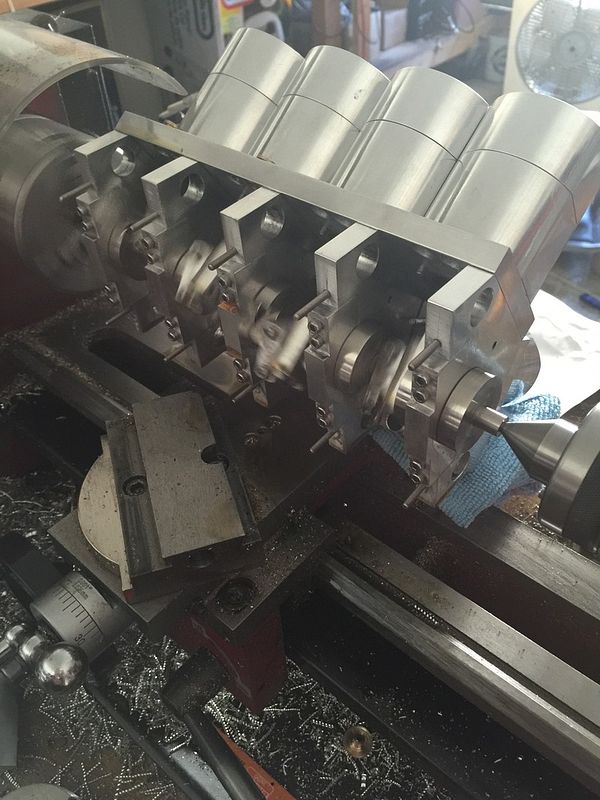

First time poster and relatively new machinist(6 months maybe). I've made a couple of steam engines, first was a single cylinder double acting steam engine from plans, the second is a 4cyl double acting engine that I just made without plans, and works very well, in fact I can power it with lung power alone.

Anyway, I'm making my first IC engine and have decided with a v8 four stroke nitro engine. It's progressing well and my inspiration came from an engine made by DickinOhio. I found this a fantastic looking engine and wanted something similar.

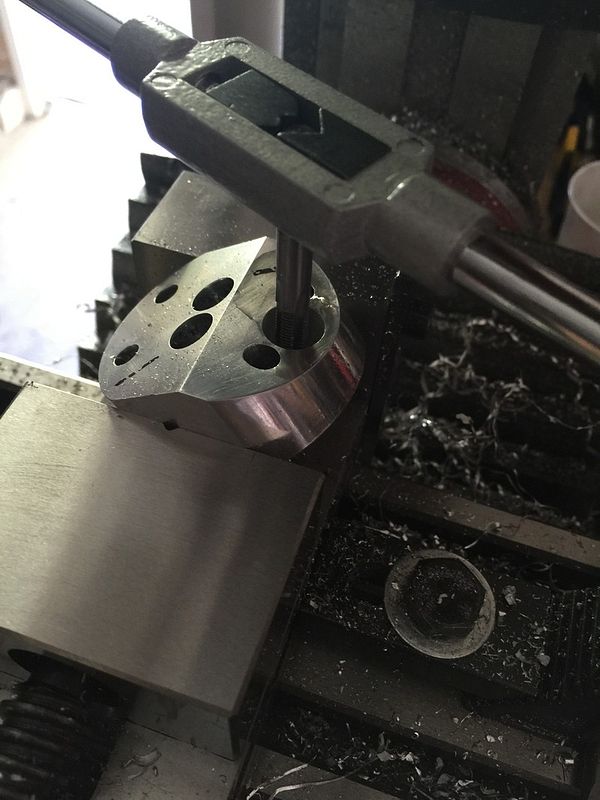

I've just finished making piston rings and running them in on the lathe, and they sure add a lot of resistance to the engine. Is this the norm? Without the rings installed, the crank spun nice and freely, even with Pistons installed.

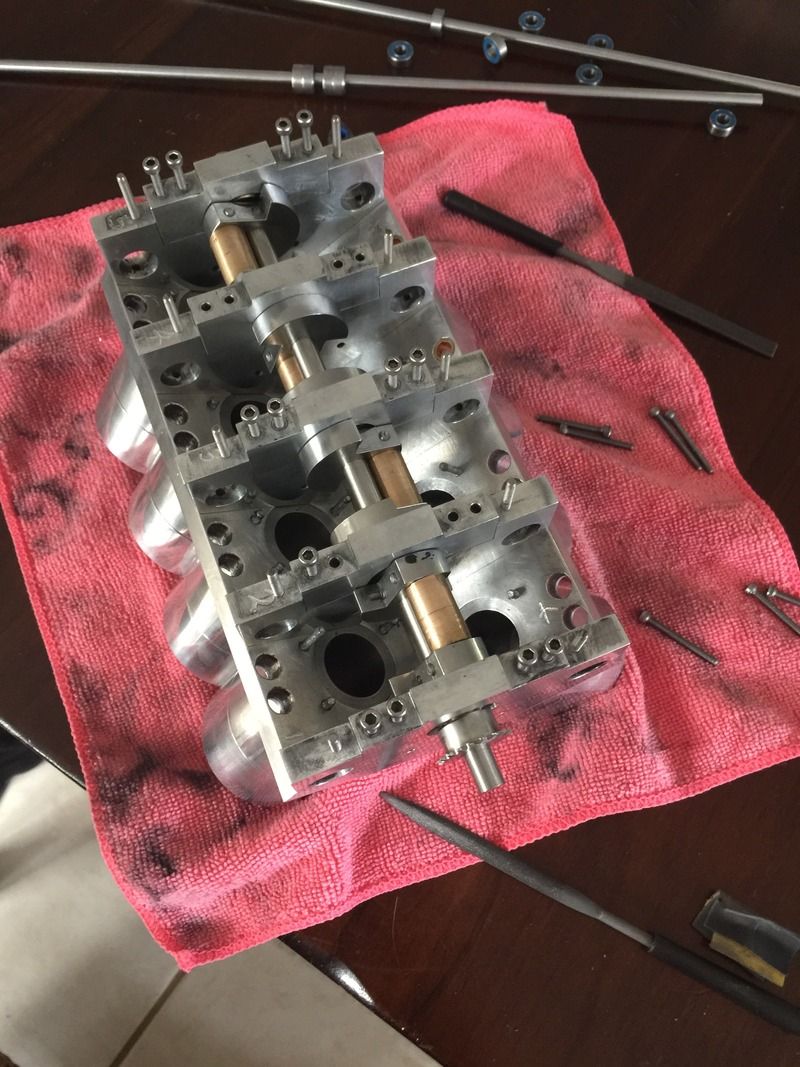

I'm starting to work on the heads and will be making bronze valve cages with stainless valves. What is the preferred material for the rocker arms?

Thanks all for viewing and I'm sure I'll have a lot more questions later on.

Cheers

Andy

First time poster and relatively new machinist(6 months maybe). I've made a couple of steam engines, first was a single cylinder double acting steam engine from plans, the second is a 4cyl double acting engine that I just made without plans, and works very well, in fact I can power it with lung power alone.

Anyway, I'm making my first IC engine and have decided with a v8 four stroke nitro engine. It's progressing well and my inspiration came from an engine made by DickinOhio. I found this a fantastic looking engine and wanted something similar.

I've just finished making piston rings and running them in on the lathe, and they sure add a lot of resistance to the engine. Is this the norm? Without the rings installed, the crank spun nice and freely, even with Pistons installed.

I'm starting to work on the heads and will be making bronze valve cages with stainless valves. What is the preferred material for the rocker arms?

Thanks all for viewing and I'm sure I'll have a lot more questions later on.

Cheers

Andy