zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Well I've got my shop back and my machines adjusted and cleaned.

Time for a project.

It's a Saxony Spinning Wheel (aka Cinderella Wheel).

Hey! It counts! It's a finger-treadle engine and I've seen those on the forum. ;D

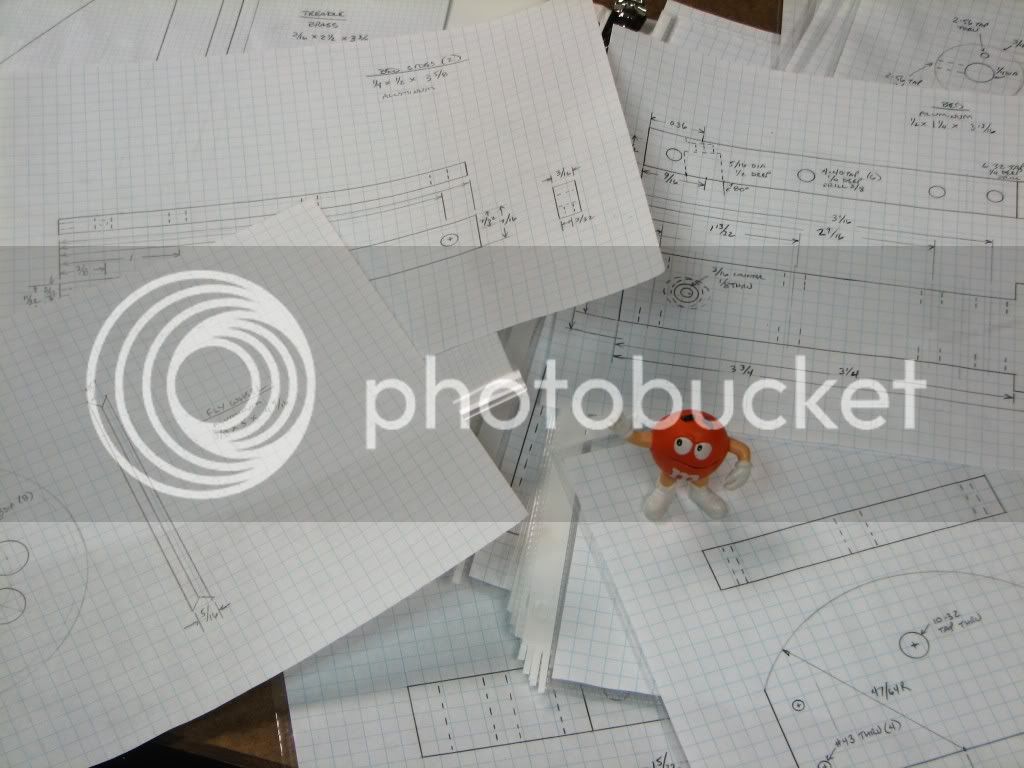

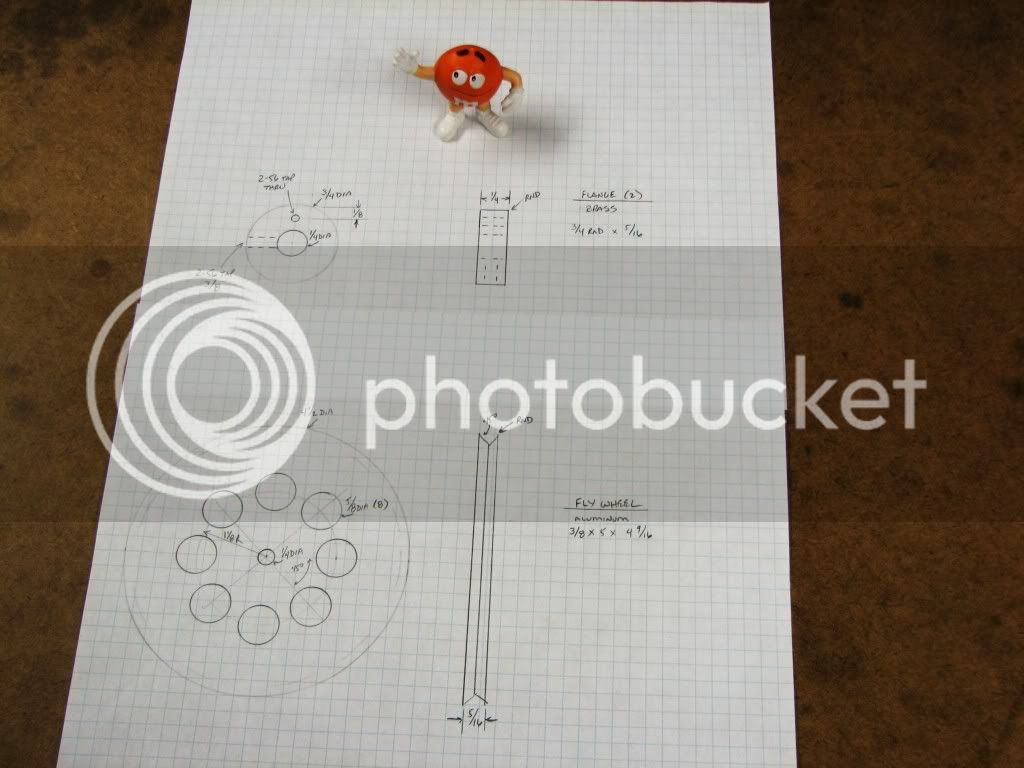

I got the plans for a full scale model and spent the holidays drawing a 1/4 scale version.

Paper and pencil...I still can't motivate myself to use a drawing tool on the PC.

I do enough mouse handling at work.

I chose this for a number of reasons:

1) Get more experience (better at machining) without risking a lot of work making a complicated part only to screw it up at the end.

2) Get some experience polishing (I want it shiny shiny).

3) Get more understanding of tolerances and sizes.

4) Make a gift for my daughter whose hobby is spinning (and as a bribe for the killer jams she makes).

The model will be made of aluminum and brass. Cost of materials is about $15.

About a third of that is in the pedal alone because it's brass.

Actual cost is yet to be determined. ;D I ordered several times as much just in case. Okay okay...I was wanting to build up some metal stock too.

mini-zeepster went west to stay with a buddy.

Allow me to introduce the new mini-zeepster.

I call him zeepee.

Don't confuse that with 'zippy'. I've been called that...but she wasn't too upset. ;D

Metal has been ordered. Now we wait.

What's the final goal you ask? Well I could use it to spin some thread and make a new tu-tu.

But I don't do sewing.

Gee zeepee looks a little naked.

P.S. The pic above is just an image I found. The one I'm making doesn't look anything like it. Nothing like it. It never would anyway.

Time for a project.

It's a Saxony Spinning Wheel (aka Cinderella Wheel).

Hey! It counts! It's a finger-treadle engine and I've seen those on the forum. ;D

I got the plans for a full scale model and spent the holidays drawing a 1/4 scale version.

Paper and pencil...I still can't motivate myself to use a drawing tool on the PC.

I do enough mouse handling at work.

I chose this for a number of reasons:

1) Get more experience (better at machining) without risking a lot of work making a complicated part only to screw it up at the end.

2) Get some experience polishing (I want it shiny shiny).

3) Get more understanding of tolerances and sizes.

4) Make a gift for my daughter whose hobby is spinning (and as a bribe for the killer jams she makes).

The model will be made of aluminum and brass. Cost of materials is about $15.

About a third of that is in the pedal alone because it's brass.

Actual cost is yet to be determined. ;D I ordered several times as much just in case. Okay okay...I was wanting to build up some metal stock too.

mini-zeepster went west to stay with a buddy.

Allow me to introduce the new mini-zeepster.

I call him zeepee.

Don't confuse that with 'zippy'. I've been called that...but she wasn't too upset. ;D

Metal has been ordered. Now we wait.

What's the final goal you ask? Well I could use it to spin some thread and make a new tu-tu.

But I don't do sewing.

Gee zeepee looks a little naked.

P.S. The pic above is just an image I found. The one I'm making doesn't look anything like it. Nothing like it. It never would anyway.