Hi all this is my first real go at making a working model its my own design of a virtical steam engine using common slide valve setup. It's been a steep learning curve so far learning to make wooden patterns making sand molds and casting aluminium and brass. I've made it quite a large model so that I can use standard cheep metric fasteners ball bearings and silver steel. Bout £100 in so far including making my furnace and patterns the rest was scap. I've got abouts 8 weeks in it so far from pen on paper most of that time spent making the patterns it's not really a scale model of eny real engine just my take on a stuart virtical made using my experience being a mechanical fitter working a on large industrial machines and everything I've learned reading this forum ta guys.

it's not really a scale model of eny real engine just my take on a stuart virtical made using my experience being a mechanical fitter working a on large industrial machines and everything I've learned reading this forum ta guys.

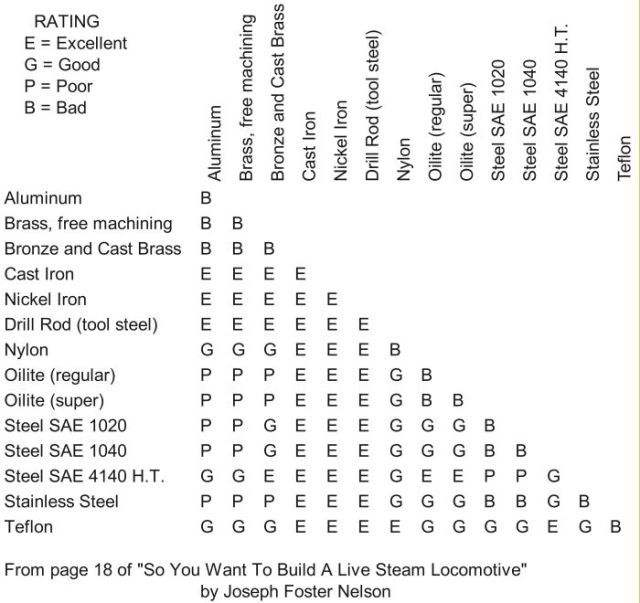

Just a few questions what are your opinions on my stainless steel cylinder liner?

Also would any one be interested in a set of drawings and castings at a resonate price it seams such a shame not to use my patters again. Sorry guys gramme is not my strong point any how some pics for you so far I shall try and take more pics of machining and casting now I have a new camera

Just a few questions what are your opinions on my stainless steel cylinder liner?

Also would any one be interested in a set of drawings and castings at a resonate price it seams such a shame not to use my patters again. Sorry guys gramme is not my strong point any how some pics for you so far I shall try and take more pics of machining and casting now I have a new camera