Yeah thanks. Sometimes I wear myself out.......... Going to finish up the 5C back plate today and get started hacking Even if is Wrong. If I can get this first build out of the way maybe I'll have a little more direction in my life........or not.....lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

THE 33?

- Thread starter 1hand

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1hand said:Yeah thanks. Sometimes I wear myself out.......... Going to finish up the 5C back plate today and get started hacking Even if is Wrong. If I can get this first build out of the way maybe I'll have a little more direction in my life........or not.....lol

Take your good old time with that back plate, and please do post any concerns, questions, and progress that you make.

-MB

Well here we go, no turning back now.

.0005 is the best I can do. Can't do any better than the spindle is. I guess I happy with that, being NASA hasn't called yet. Now I feel I should upgrade to that better 4 jaw. 4" or 6" or both? Man my lathe is a mess now. Going to spend the rest of the afternoon cleaning that up. Good ol cast!!

Matt

.0005 is the best I can do. Can't do any better than the spindle is. I guess I happy with that, being NASA hasn't called yet. Now I feel I should upgrade to that better 4 jaw. 4" or 6" or both? Man my lathe is a mess now. Going to spend the rest of the afternoon cleaning that up. Good ol cast!!

Matt

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Good deal! Man that was quick! Glad it turned out well for you. We all need to get an important one in the win box. That plate must be the good one from LMS, or you would be machining it till Monday. Did you like the way it machined?

Many of the China made '5C Collet Chuck' sellers give a spec at .001" run out. Unless you paid $450 to $500 you should be completely satisfied that you got a great chuck at a good price.

Looks like your ready to "Rock and Roll." :big:

-MB

Many of the China made '5C Collet Chuck' sellers give a spec at .001" run out. Unless you paid $450 to $500 you should be completely satisfied that you got a great chuck at a good price.

Looks like your ready to "Rock and Roll." :big:

-MB

It machined alright I guess, never turned cast before, so??? could only take .010 per pass or the lathe would stall out "don't ask me how I know this". Kool mist really helped. But what a mess. Looks like I've been in the coal factory.

Matt

Matt

Metal Butcher said:.....When your face is up against a tree, you turn around and ask your friends, "where is the forest? And they say "Were standing in it!" I know its a little corny........

-MB

That's funny, most of my friends tell me to "stay there!" scratch.gif Rof} Rof} Rof}

It sounds like you did just fine on the chuck, Matt. You're within .0001 of what Bison advertises. Not too shabby at all! Collets are nice to work with, too. A nice added convenience for your shop!

Dean

(edited for spelling... to, too, two, tu-tu, etc.)

Dean

(edited for spelling... to, too, two, tu-tu, etc.)

Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Looks good so far Matt!!

Matt, do you want to be able to get the parts apart without a big struggle, or to stay put forever?

There are different kinds, but as far as I know, they all work with steel, brass, aluminum. They are graded by strength, and how hard it is to get parts disconnected from each other.

Dean

There are different kinds, but as far as I know, they all work with steel, brass, aluminum. They are graded by strength, and how hard it is to get parts disconnected from each other.

Dean

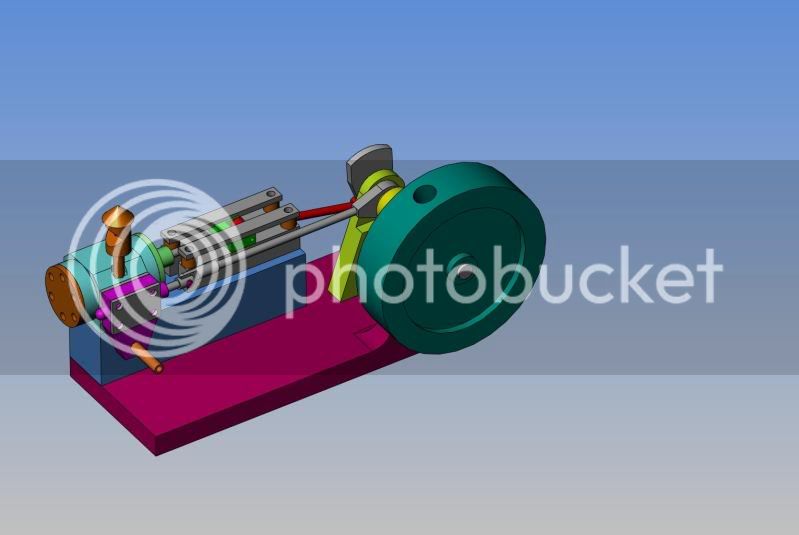

Well we're changing directions yet again.... ??? After figuring material prices, I've decided to build the Elmer's Engines in their planned scale. If I'm going to build them all, my kids may go hungry if I up-scale, And where would I display such a vast collection of over size modeling marvels?..........LoL.. :

Well enough of that. Here's what I did so far. Cut the parts that I had material for.

MB; It's A Start........ woohoo1

Matt

Well enough of that. Here's what I did so far. Cut the parts that I had material for.

MB; It's A Start........ woohoo1

Matt

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Matt, You may find some of the smaller parts a bit tedious. I do on most of the engines I built. Just take your time, make one part at a time, and it'll all come together. Shelf space can become a problem after a while, that's why I like the size of most of Elmer's Engines. If I up-size on some of Elmer's smaller engines, they still fit within a foot print size of 6" x 6". And that's about the size that I like.

I love the picture you posted. It looks just like my workbench at the start of a new build!

Make sure you keep with the HMEM tradition, and post plenty of pictures! 8)

-MB

I love the picture you posted. It looks just like my workbench at the start of a new build!

Make sure you keep with the HMEM tradition, and post plenty of pictures! 8)

-MB

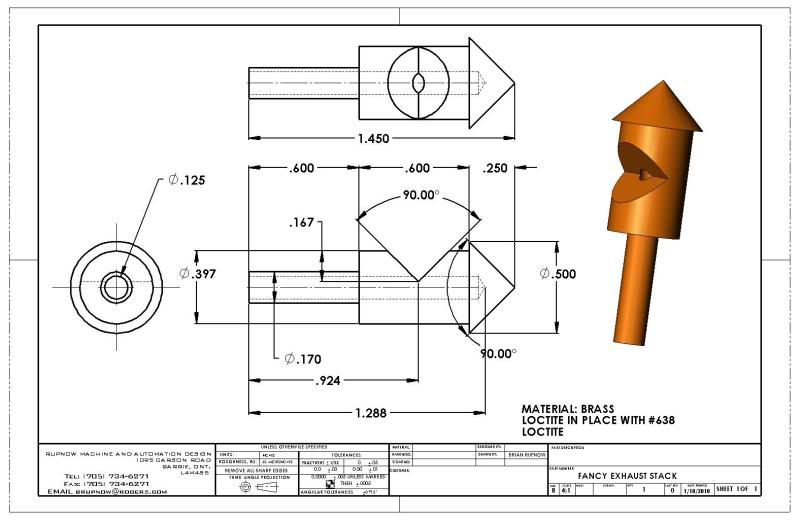

Thanks Brian for the add-on Bling. I sure like the looks of that on your engine. Sure gives it that traditional steam look. Thm:

MB ; thanks for the addvice. Nice and easy...........gotch ya!

Working on a face plate .. drive plate so I can turn the CYL. like Brian did. Drive holes are to far out on the face plate to catch the CYL block so I'm putting a drive plate across. I'll post some pics when I get a bit more done, just sawed the plate now.

Thanks guys,

Matt

MB ; thanks for the addvice. Nice and easy...........gotch ya!

Working on a face plate .. drive plate so I can turn the CYL. like Brian did. Drive holes are to far out on the face plate to catch the CYL block so I'm putting a drive plate across. I'll post some pics when I get a bit more done, just sawed the plate now.

Thanks guys,

Matt

The hardware store doesn't carry the Loc-tite brand, but they had Permatex high strength RED. So hopefully this is good enough for the drive pins. I don't plan on doing the CyL block for awhile til I find my comfort zone doing some of the other easier parts, So if this Permatex isn't the stuff, let me know. I'll take it back. $9 for .20 fl oz.

th_confused0052

th_confused0052

I'm not sure about Permatex---I have only heard of it in relation to gasket materials. Loctite can be generally found at industrial suppliers or at nut and bolt stores like Fastenal.

Well here I'm making a drive plate to make up for the gap between the dead center and the start of the drive/mounting holes.

A piece of .5 x 2.0 drilled 1.0 for dead center clearance, And two .5 x 13 tapped holes for mounting.

A test fit for the bolt holes.

Tight fit here. About the max turning diameter for the QCTP in the stock location.

Rounding the edges will make for a fast setup. Match the curves and tighten down, Will be right in the center.

Measuring up the length for the drive slot.

Transfer da measurement.

To da mill.

Drilling the work piece for the drive dog.

There she is.... Going to be a real handy for some operations later on down da road.

Matt

A piece of .5 x 2.0 drilled 1.0 for dead center clearance, And two .5 x 13 tapped holes for mounting.

A test fit for the bolt holes.

Tight fit here. About the max turning diameter for the QCTP in the stock location.

Rounding the edges will make for a fast setup. Match the curves and tighten down, Will be right in the center.

Measuring up the length for the drive slot.

Transfer da measurement.

To da mill.

Drilling the work piece for the drive dog.

There she is.... Going to be a real handy for some operations later on down da road.

Matt

Hi Matt;

The place to get Locktite is an auto parts store, unless you are near an industrial supply. I've never seen a NAPA or Pep Boys that didn't have it.

I'm not sure about Permatex, either. Most of what they make is a paste, like RTV sealant. Maybe they make a Locktite copy.

Thread locker like we're talking about is thin as water, and comes in different colors and different strengths. It will say Locktite ThreadLocker Blue, or Green, or Red, etc. If you are just asking about it in relation to holding pins on this engine, then any one of them will work. The blue kind, called Locktite 242 is easiest to work with if there is some chance that you may need to remove what ever it is you've locked.

You can get it in a tiny tube, or a small bottle. Big bottles too, but big bucks.

Dean

The place to get Locktite is an auto parts store, unless you are near an industrial supply. I've never seen a NAPA or Pep Boys that didn't have it.

I'm not sure about Permatex, either. Most of what they make is a paste, like RTV sealant. Maybe they make a Locktite copy.

Thread locker like we're talking about is thin as water, and comes in different colors and different strengths. It will say Locktite ThreadLocker Blue, or Green, or Red, etc. If you are just asking about it in relation to holding pins on this engine, then any one of them will work. The blue kind, called Locktite 242 is easiest to work with if there is some chance that you may need to remove what ever it is you've locked.

You can get it in a tiny tube, or a small bottle. Big bottles too, but big bucks.

Dean

Napa was closed. Only thing I could find at the time. I use Loc-tite at work, and this Permatex seams to be the same stuff. It says it takes 230 in lbs to break. So I figure I'll give it a try and report back.

Thanks, Matt

Thanks, Matt

Transfer da measurement.

To da mill.

Yo; If yer gonna talk da Yooper, ya talk da Yooper all a' da time, eh?

; )

Looks like you're off to a bang up start, Matt.

It sounds like you got a proper clone with the Permatex. Should do fine.

Dean

Similar threads

- Replies

- 23

- Views

- 1K