deere_x475guy

Well-Known Member

7 years ago I bought a machinist level from WT tool. I used it to level my lathe and put it away. Then about a year later I took it over to a friends house to check his lathe. It was then I realized that I never calibrated the darn thing.

Oh well no problem I say...I will just calibrate it first and later I will check my lathe again. We went through the calibration process and noticed it didn't seem as stable as we thought it should be.

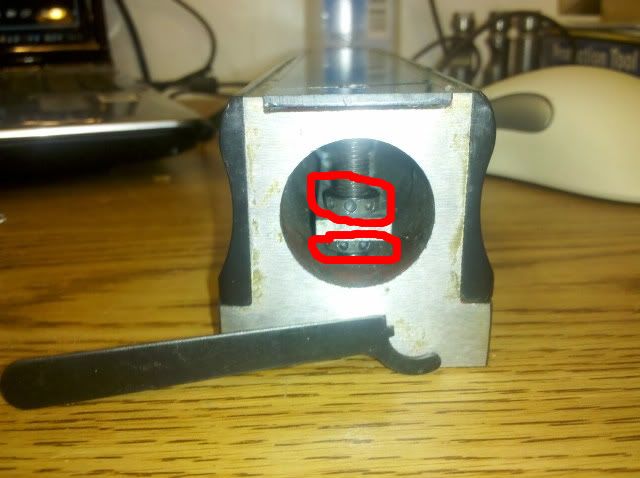

Well about 6 months later I got around to trying to adjust my lathe again....it was then I discovered there wasn't any liquid in it and the box had moisture in it. Upon taking it apart I discovered the correct way to adjust it. I had been turning the screw that goes though the body before. In if it had been assembled correctly I would never have been able to turn the screw. A round nut had been floating around inside and when I tuned the screw to adjust it the nut was against the vial and it broke.

Since then I had been trying to locate a new vial for it but was not successful. Then a few weeks ago I notice a thread that John had posted about fixing his level and having to buy several vials to get one. I emailed John and asked if I could by one from him. John told me not to worry about a change and sent one to me several weeks ago. It arrived today and here are some shots of what I did to get it to work.

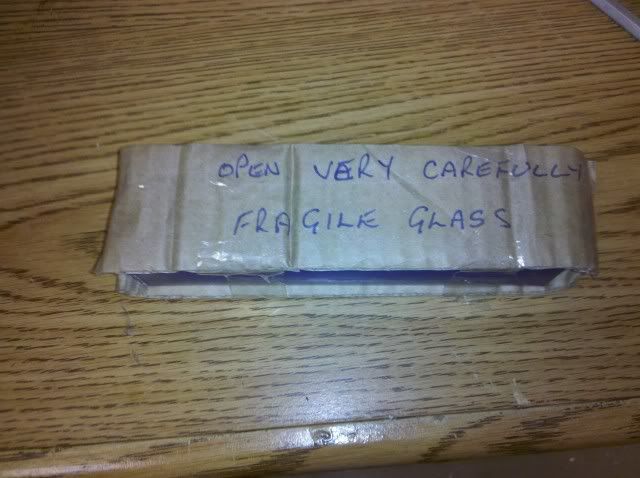

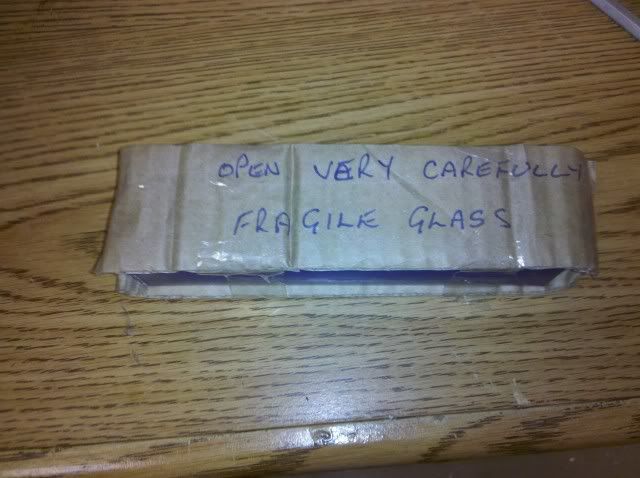

John had it well package and marked fragile. It was also in another package.

I used hot glue to hold it in place it just fit.

I now have it properly calibrated

I checked my lathe....

Here is the tailstock end

Here is the headstock...these points are 40" apart...I think this is good enough...

Thanks again John!!!....

Oh well no problem I say...I will just calibrate it first and later I will check my lathe again. We went through the calibration process and noticed it didn't seem as stable as we thought it should be.

Well about 6 months later I got around to trying to adjust my lathe again....it was then I discovered there wasn't any liquid in it and the box had moisture in it. Upon taking it apart I discovered the correct way to adjust it. I had been turning the screw that goes though the body before. In if it had been assembled correctly I would never have been able to turn the screw. A round nut had been floating around inside and when I tuned the screw to adjust it the nut was against the vial and it broke.

Since then I had been trying to locate a new vial for it but was not successful. Then a few weeks ago I notice a thread that John had posted about fixing his level and having to buy several vials to get one. I emailed John and asked if I could by one from him. John told me not to worry about a change and sent one to me several weeks ago. It arrived today and here are some shots of what I did to get it to work.

John had it well package and marked fragile. It was also in another package.

I used hot glue to hold it in place it just fit.

I now have it properly calibrated

I checked my lathe....

Here is the tailstock end

Here is the headstock...these points are 40" apart...I think this is good enough...

Thanks again John!!!....