- Joined

- Mar 3, 2008

- Messages

- 243

- Reaction score

- 20

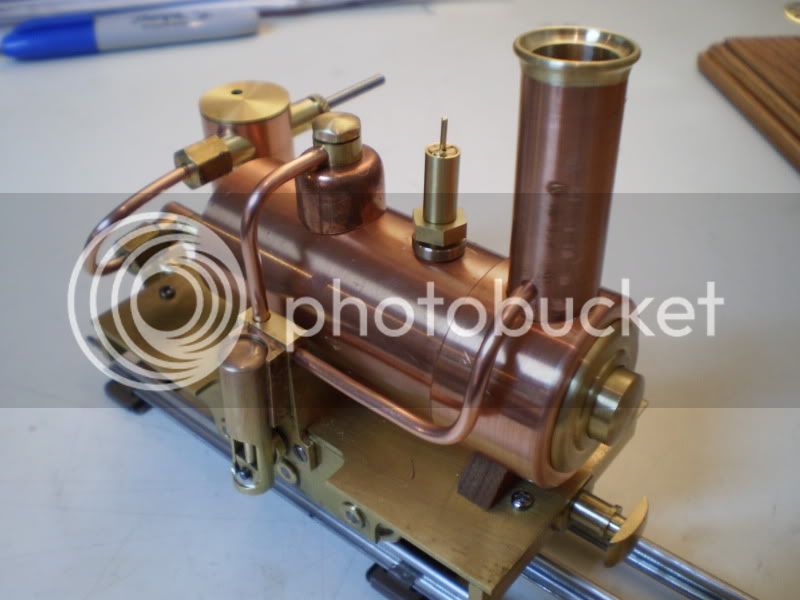

Here is my latest project....A CRACKER.

I built this for 3 reasons:

1. It's neat!

2. Even though I am not a big rail fan, I wanted to get at least one build under my belt.

3. It answers the age old question: What does it do?.........I find people just don't get the stationary engine stuff (like we do ;D)

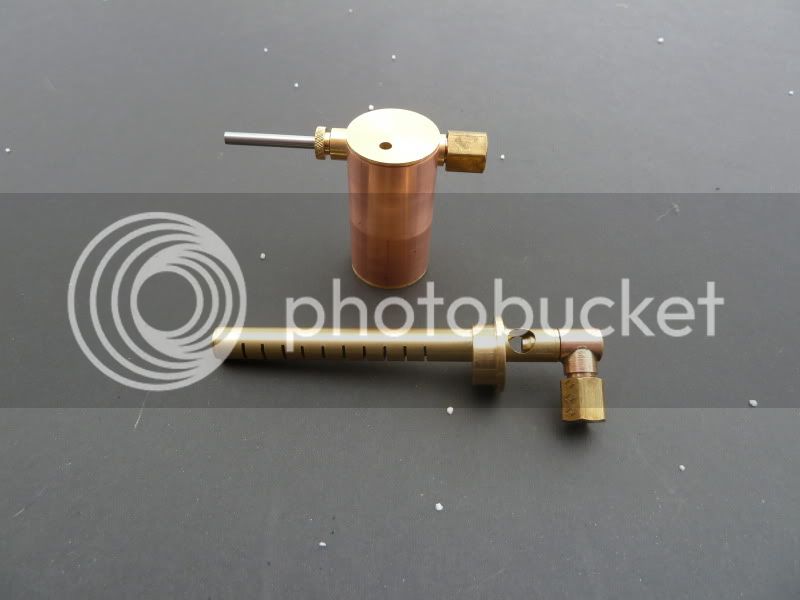

It may look done, but I still need to finish the burner and gas tank. I have tested it on air, but I will test with steam soon.

I did not do a step by step build, because it has being done before. I will post more pictures soon of the finished parts before assembly.

IronHorse

I built this for 3 reasons:

1. It's neat!

2. Even though I am not a big rail fan, I wanted to get at least one build under my belt.

3. It answers the age old question: What does it do?.........I find people just don't get the stationary engine stuff (like we do ;D)

It may look done, but I still need to finish the burner and gas tank. I have tested it on air, but I will test with steam soon.

I did not do a step by step build, because it has being done before. I will post more pictures soon of the finished parts before assembly.

IronHorse