Hi Drysdam --

It's great to see some interest in the Stirling-Steele. I was beginning to think I'd imagined the whole thing. I did begin construction of it, and got about 75% done (as my first machining exercise, actually, a bit bold perhaps...) when a sudden bout of surgery put me out of action for a while.

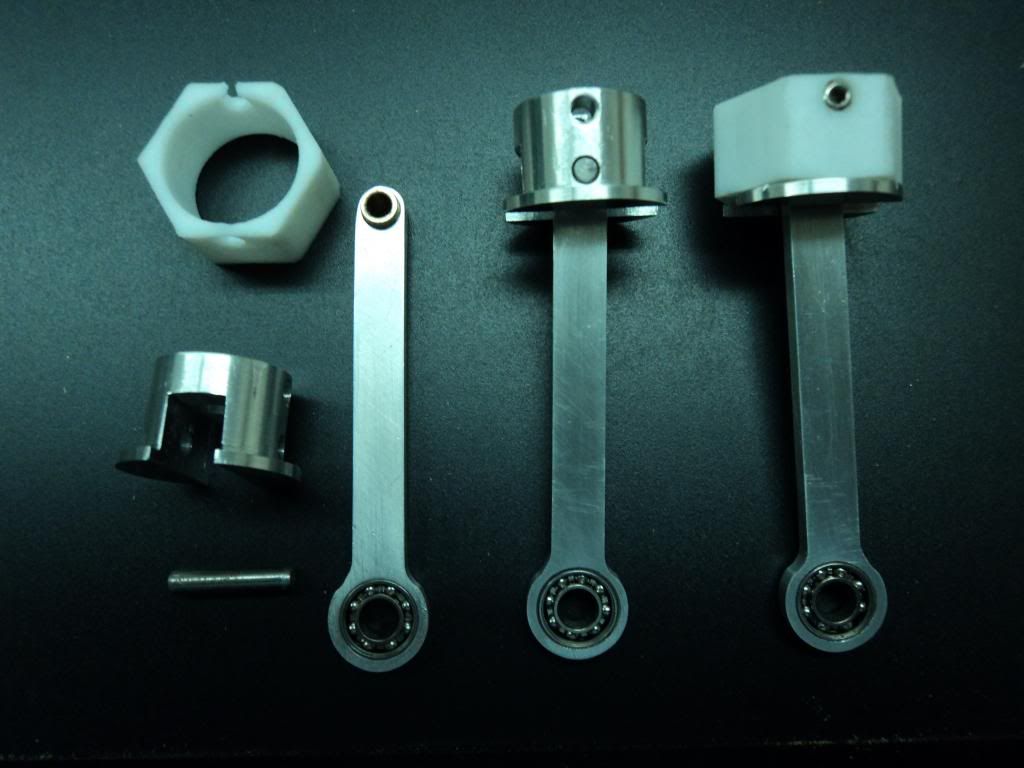

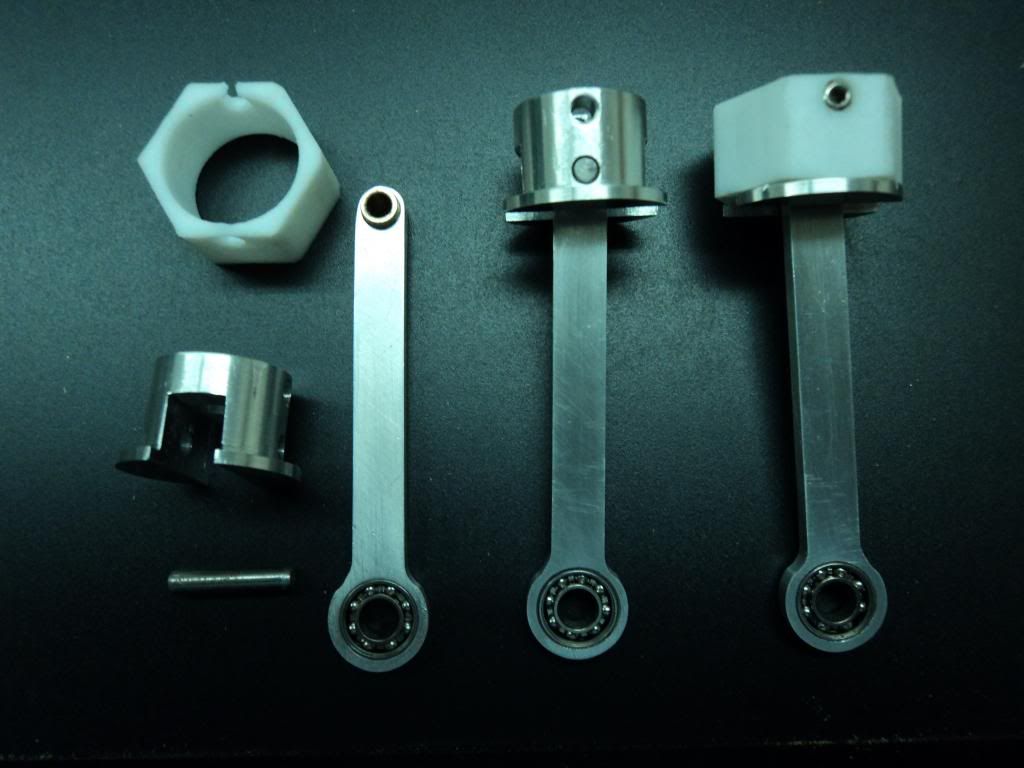

When I finally got back to the shop I kinda wanted a clean slate kind of project, and began an Edwards Radial Five, with which I'm still very much involved. I will get back to finishing the SS, which I think is a most entertaining exercise in machining, and I really like the theory behind it, but it'll have to wait until the Edwards comes alive, which is at least three months away. I did take a few pics of the SS project, though, and finally got around to unearthing a few of them today. Here's a sample of the pistons, conrods, bearings, teflon bushings, and wotnot...

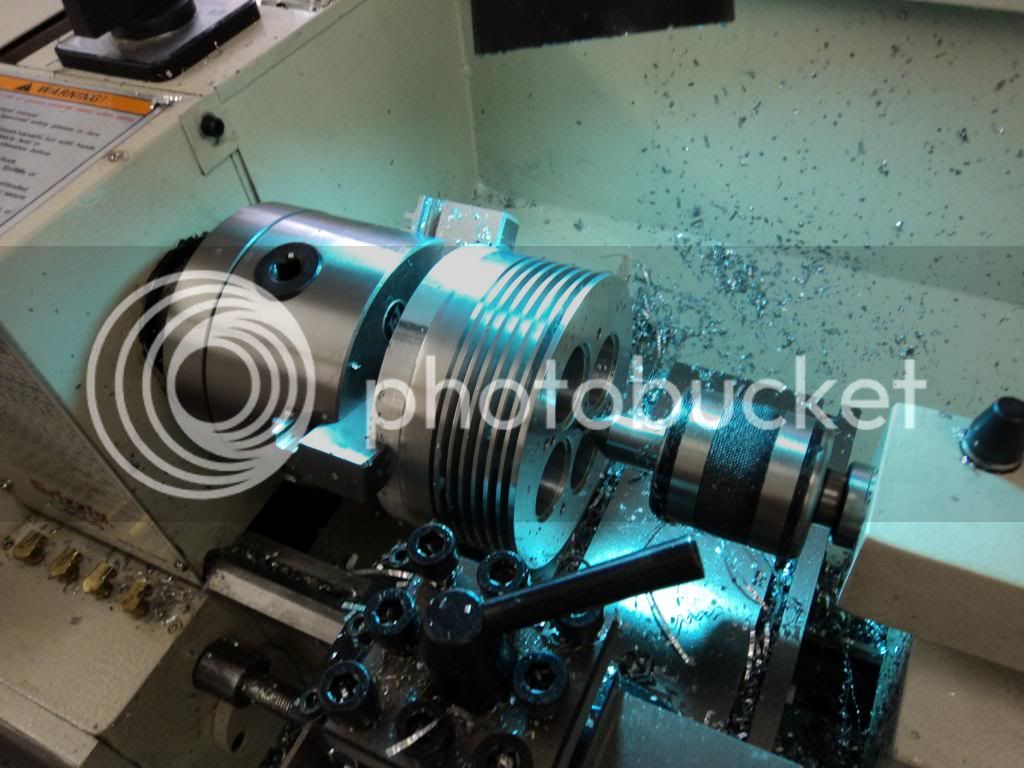

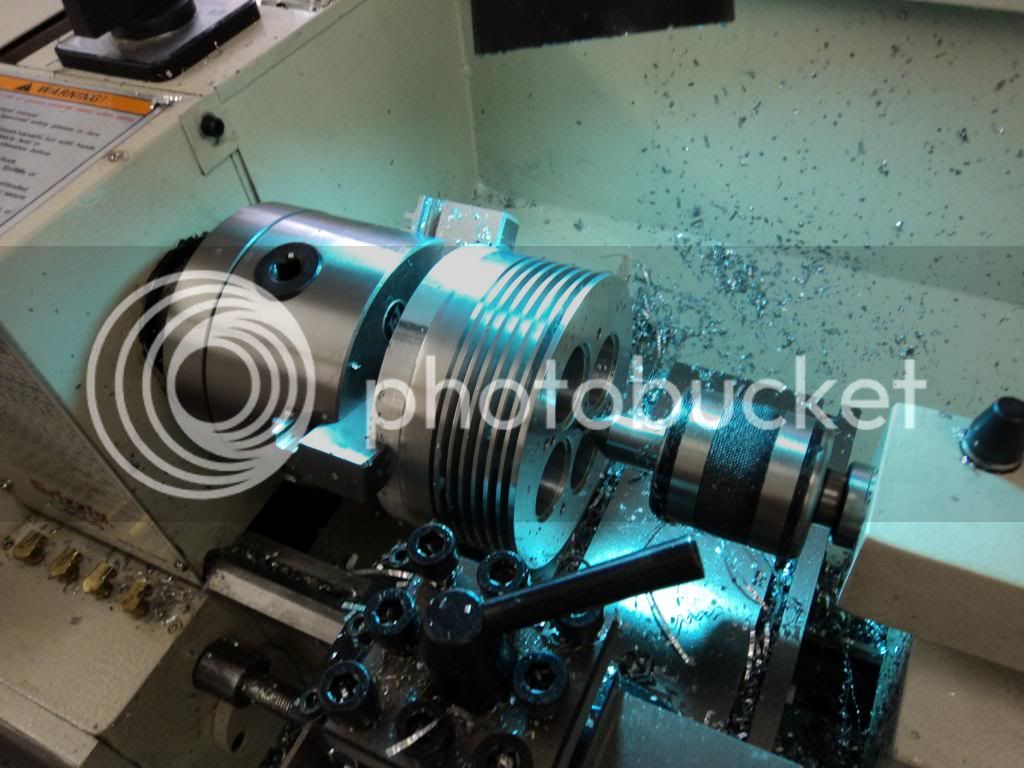

and the machining of the fins on the Displacer/Regenerator section...

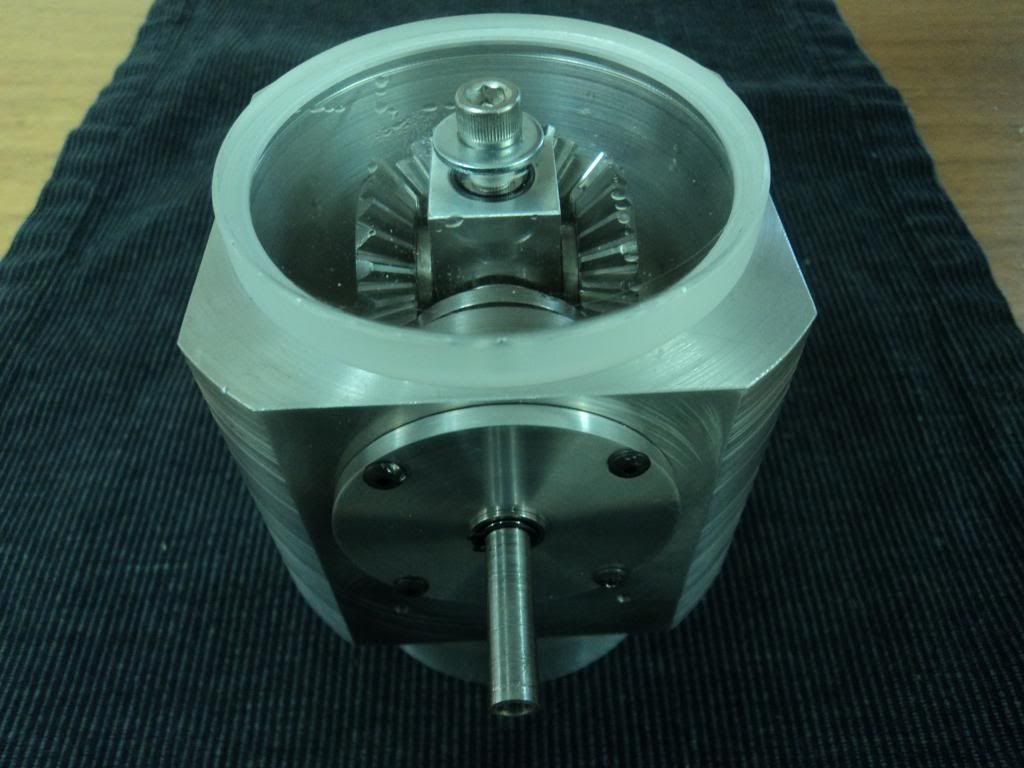

...and the completed section looking quite bored in all its grand finnery...

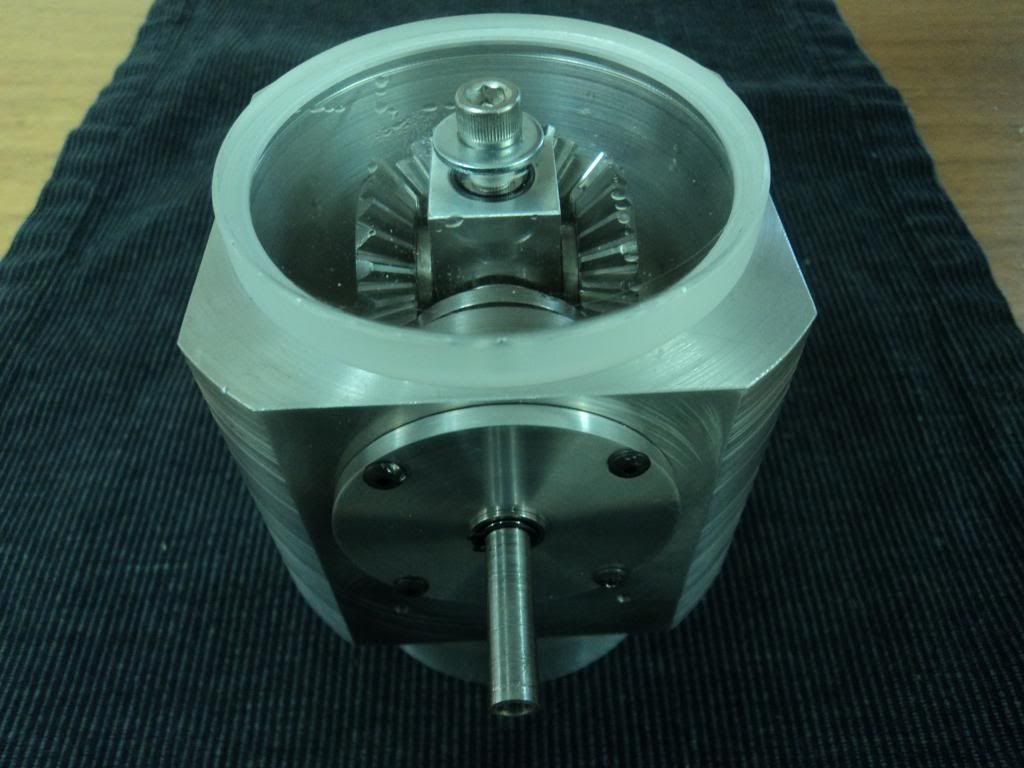

Then a blurry take on the shaft gears and such (all bevel gears unashamedly purchased, not fabricated, though they had to be cut about a bit to fit)...

...and then the same gears enclosed by the crankcase, as seen through the transparent plastic cover so thoughtfully spec'd by Mr. Steele.

The intermediate plate, the Displacer Piston Assemblies, and the Cold Sleeves are all done and accounted for...the latter the trickiest part of all. The Hot Caps are really the only serious pieces of machining left to do.

Just FYI I'm using a 9x20 Grizzly G4000 lathe, and a bench mill-drill. Also a slowly-expanding set of hand tools, home-built jigs and fixtures, and autodidactic expertise. If you're "beginning to intermediate" you're way ahead.

I must say the drawings have been pretty much spot-on so far, as they would have had to be for a first-engine-attempt project. I'll see if I can find (or even take) some more up-to-date pics if there is any interest. Certainly, I'm motivated to finish this beastie as soon as the calendar clears, and I'd be even more so if I had some company. Any takers?

Aloha, and thanks again for the interest in this intriguing motor.