This might sound a bit heath robinson but... I take the pitch from the thread dia which gives me the drill size.

I.E. M10x1.50 take the 1.50 from the 10 and you get 8.50 ... Personally I would use a 8.8 (unless I was really going for super strong thread?!)

It has worked for me so far... only one broken tap in 2 years, M4x0.7 oddly enough and that was into stainless 6mm deep hole

That was with a 3.5mm hole... I now use a 3.7mm and it holds well enough.

Anyway... Back to my post!!

I spent a few hours in the shop this eve' Some time desoldering old circuit boards, LED salvage mostly. I just need the space they take up.

The rest of the evening went to my engine.... The piston to be more precise

(yes time and date are correct... I'm just insane!!

)

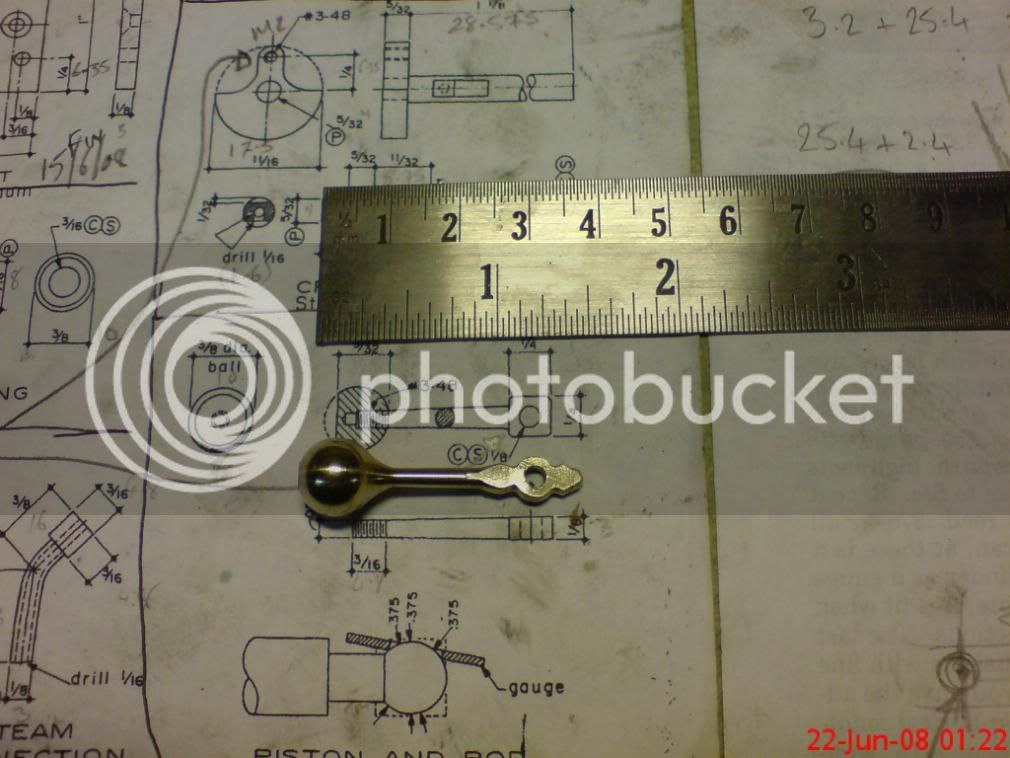

I decided to make it one part rather than the 2 in the plan...

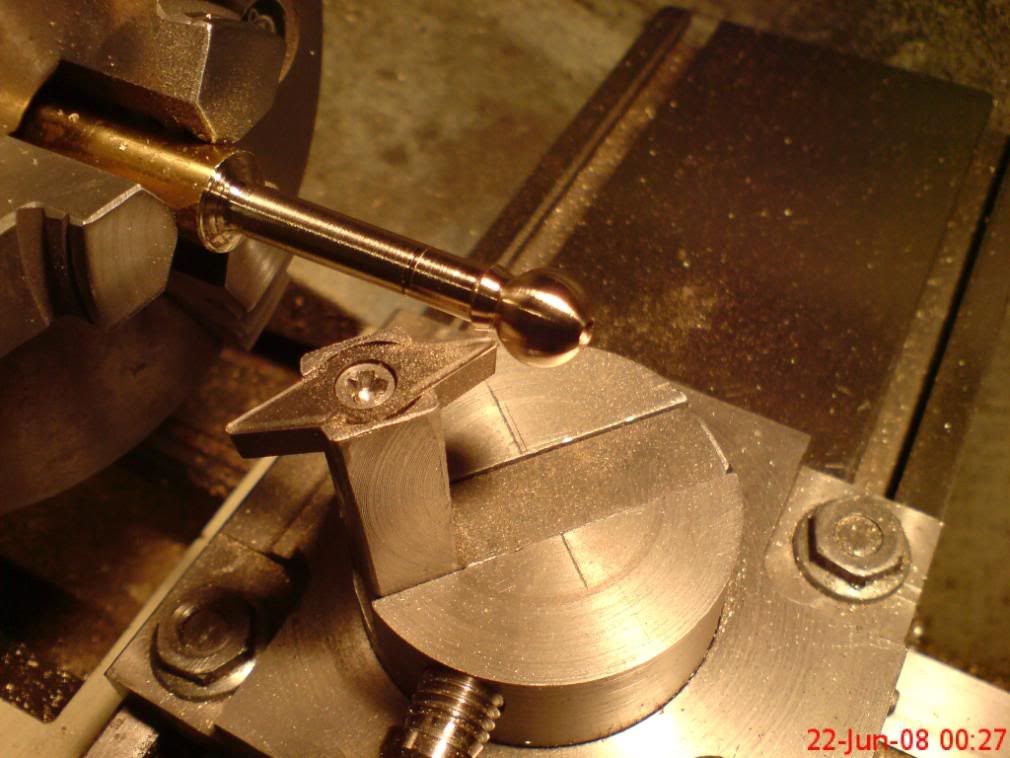

Once the ball was to the correct dia for the cylinder the part was transferred to the rotary table set up on the mill which was still set up from the drilling of the flywheel (not an accident, I made sure I had done all I could before setting the mill up this way to save all those heavy vise/RT changes) and then drilled the hole for the crank pin. Then back to the lathe for shaping....

Then my camera seems to have not wanted to save the photo's taken at the mill!?!? but basically I flattened off the sides of the conrod and then parted the piston ass'y off....

Just needs a little flat and polish on the milled end and the piston is finished ;D

Now you can carry on with the threading issue

;D

Ralph.