Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

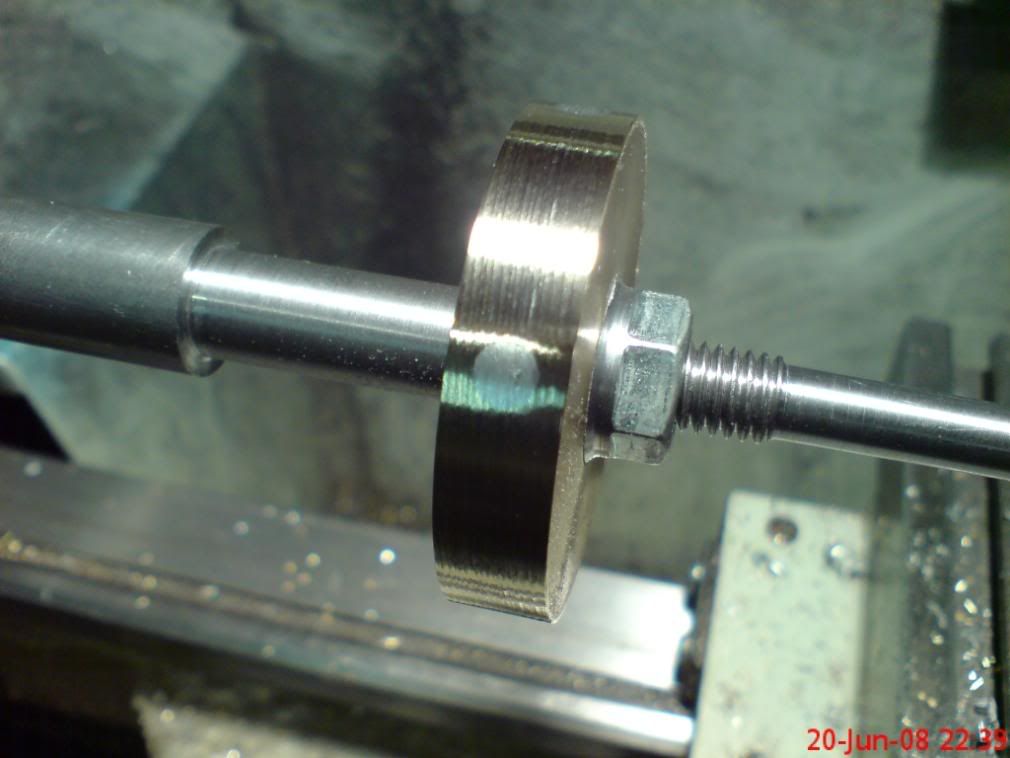

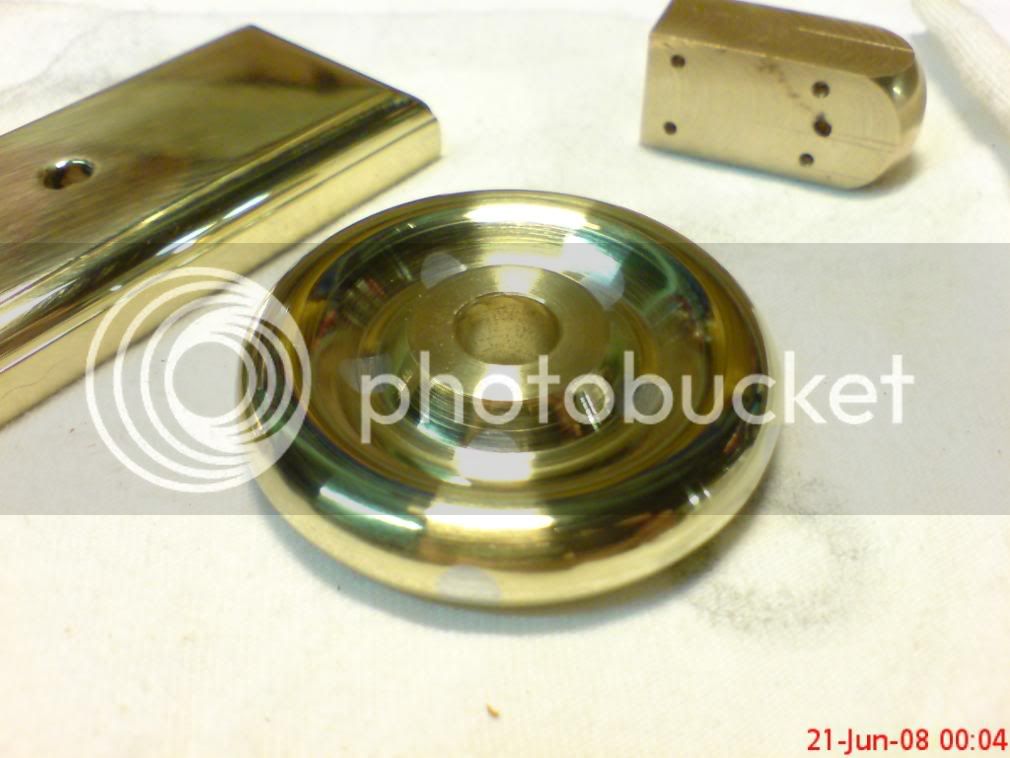

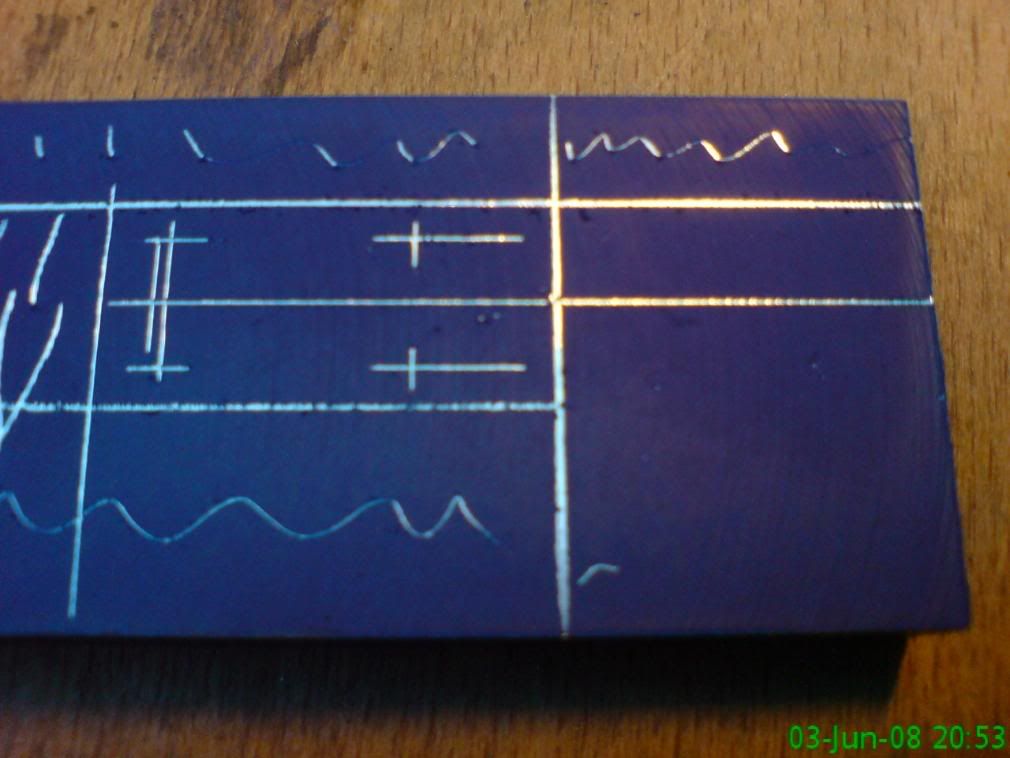

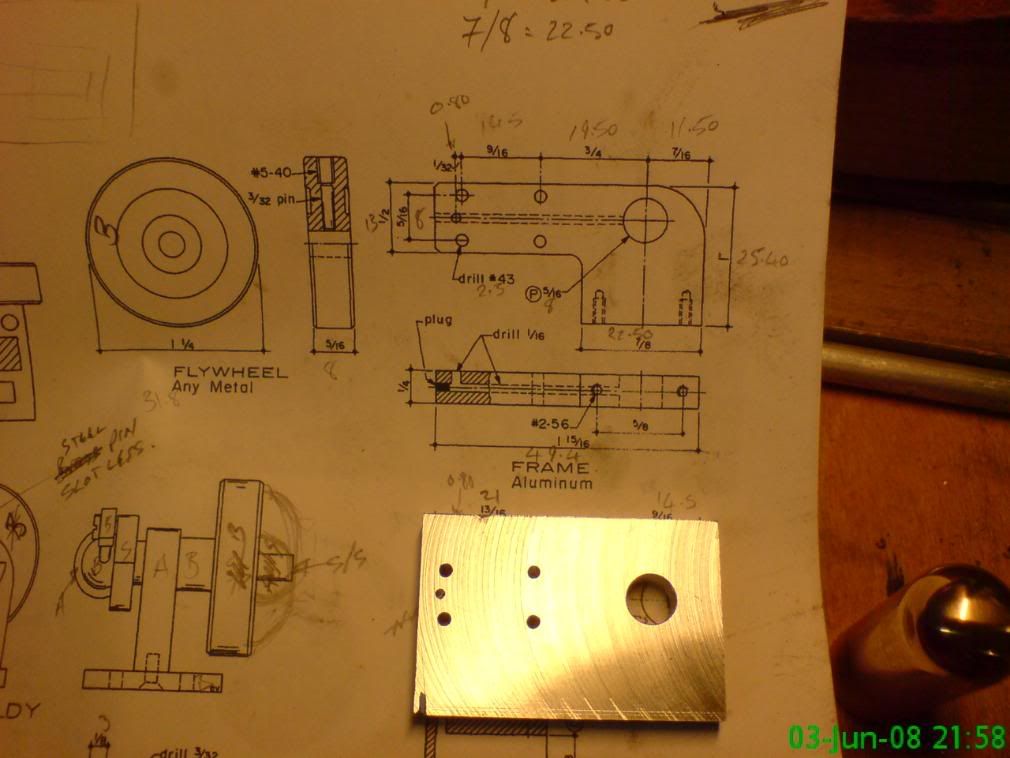

Well the time has come to get me boots wet!

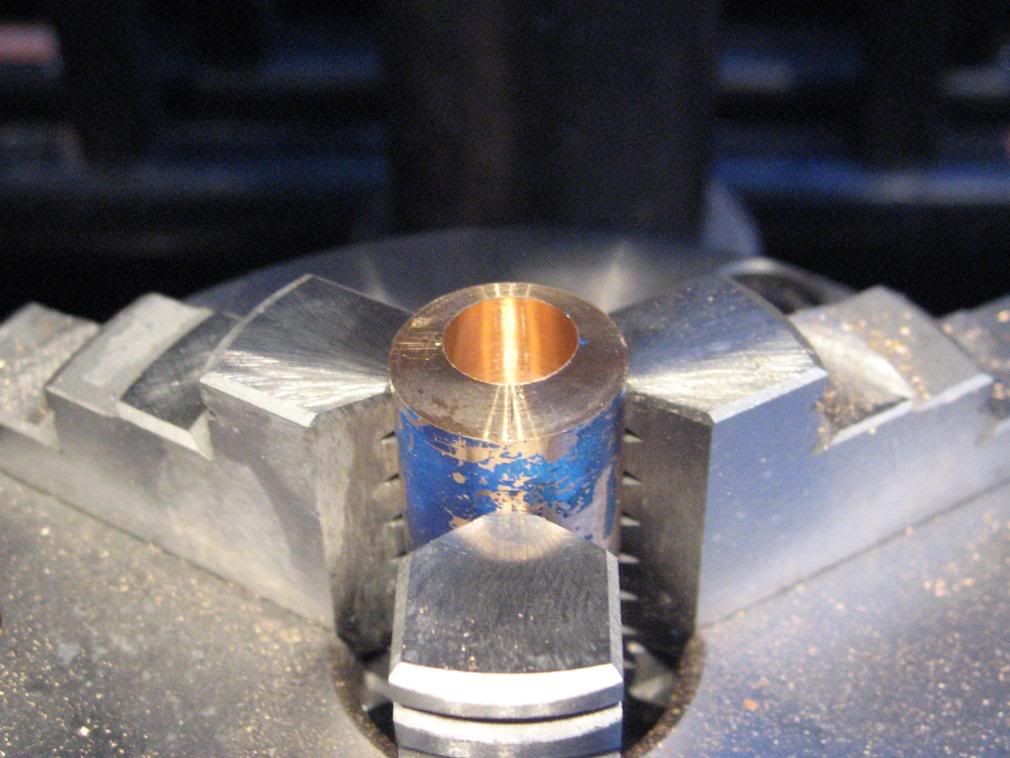

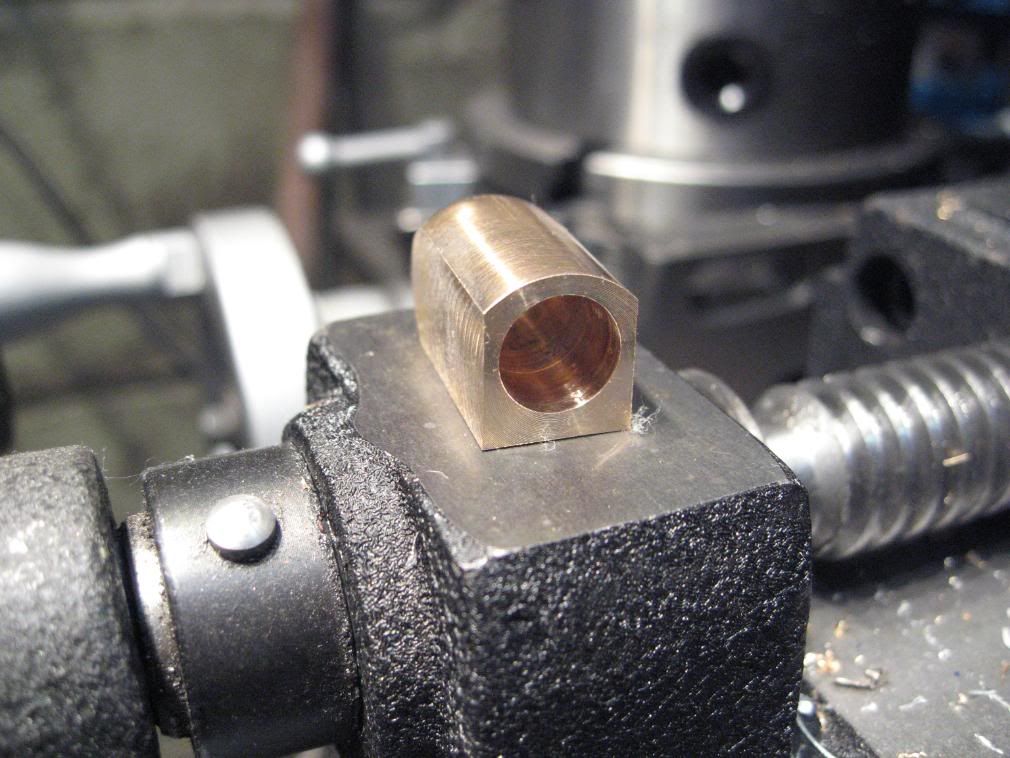

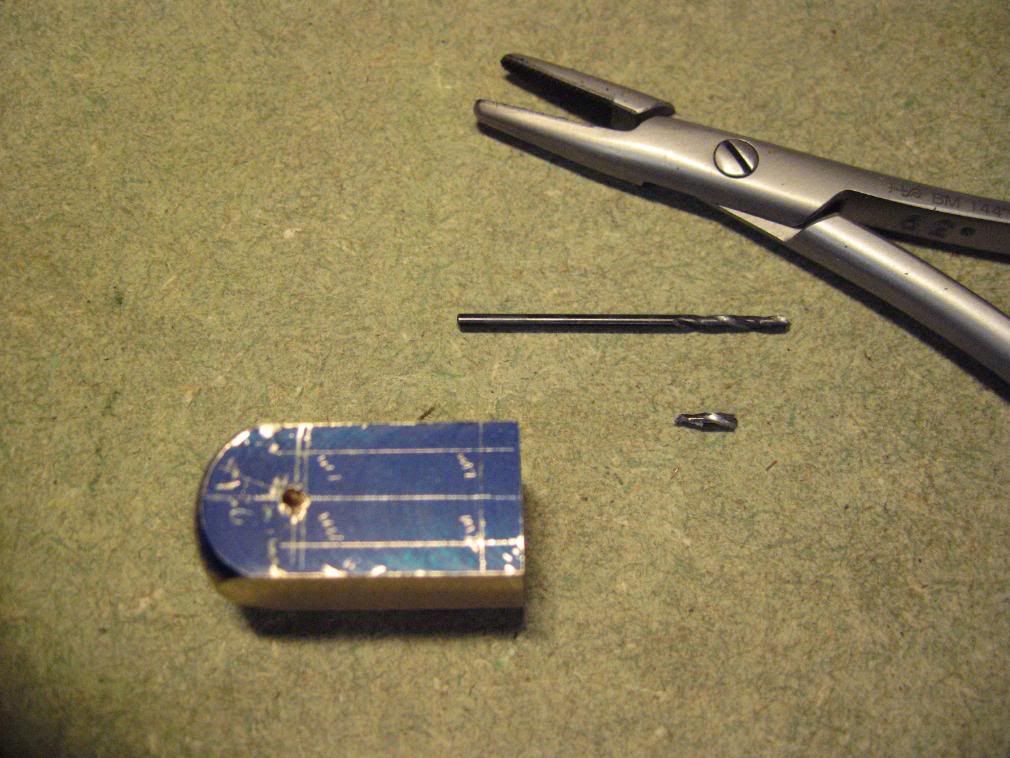

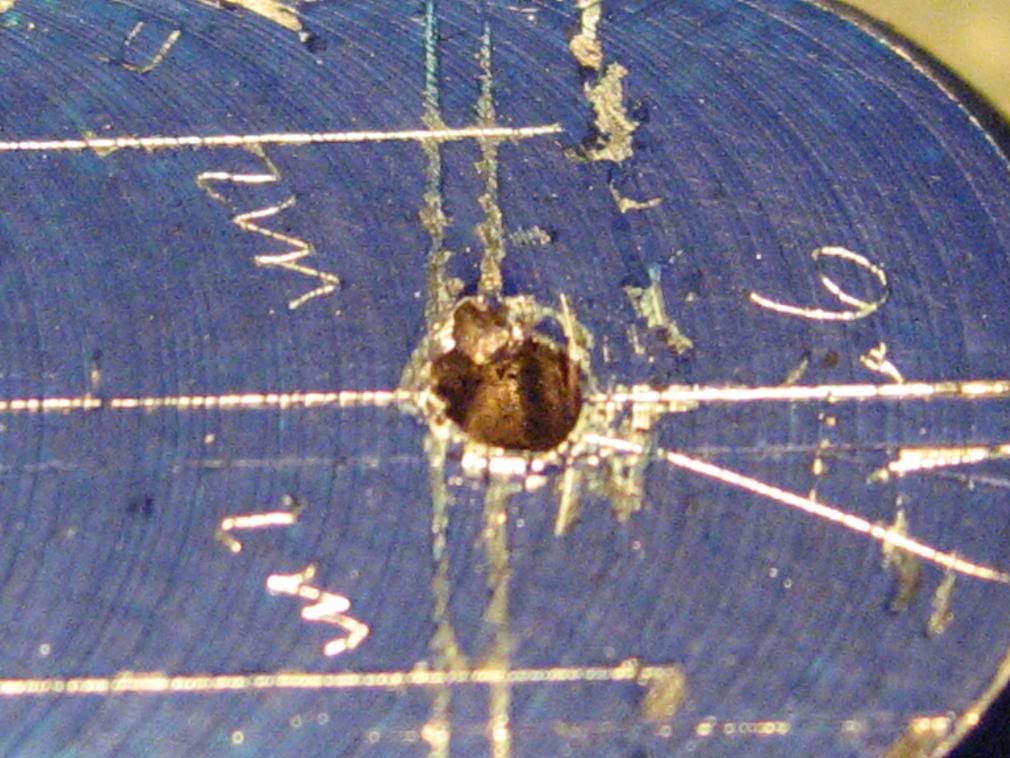

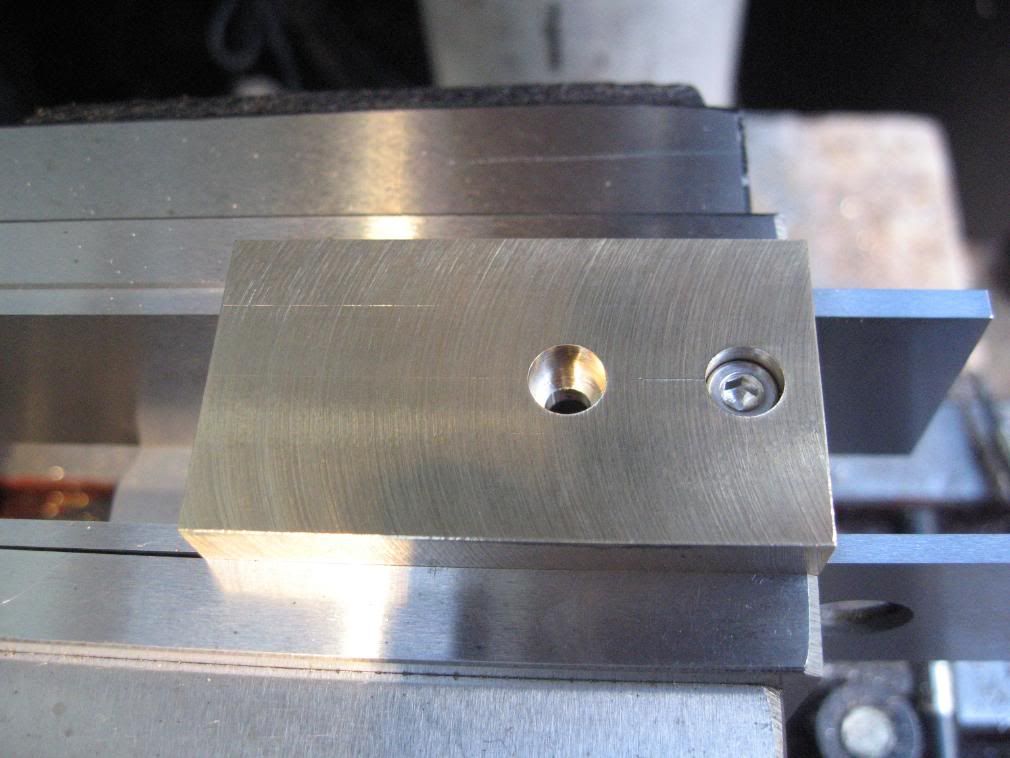

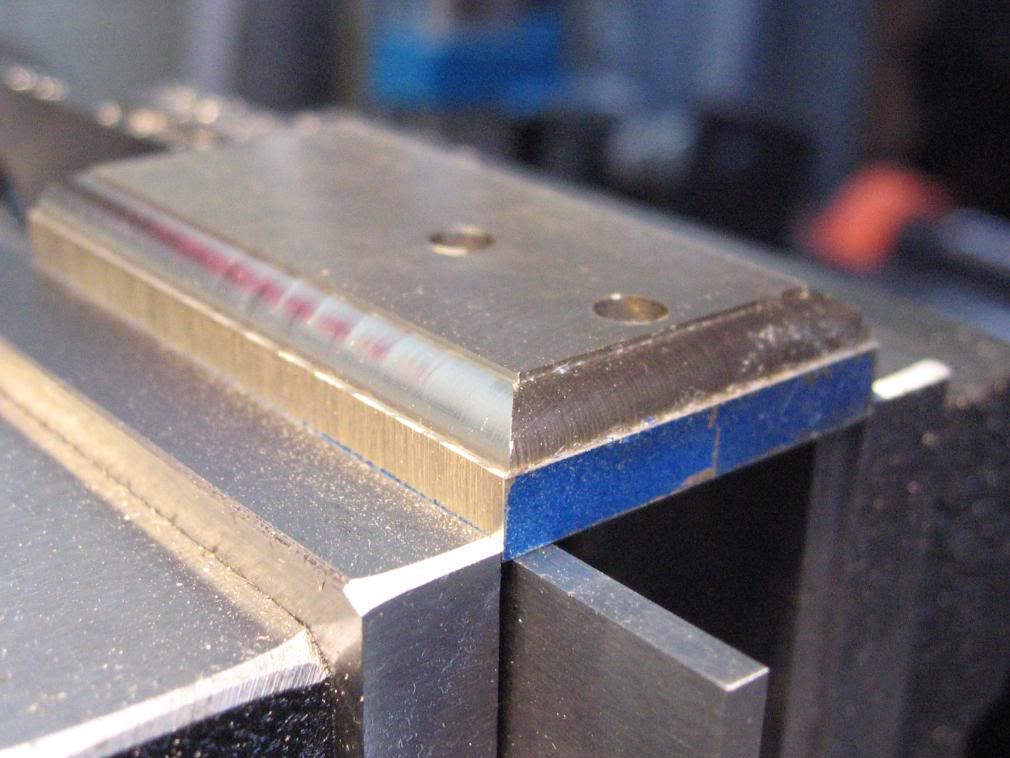

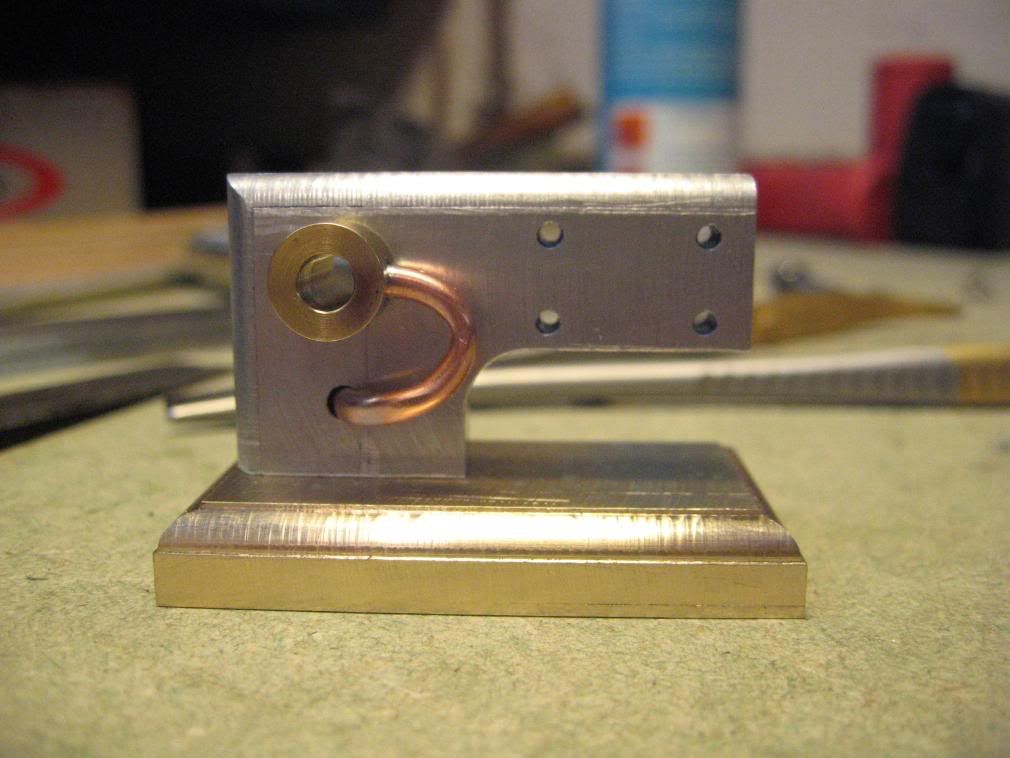

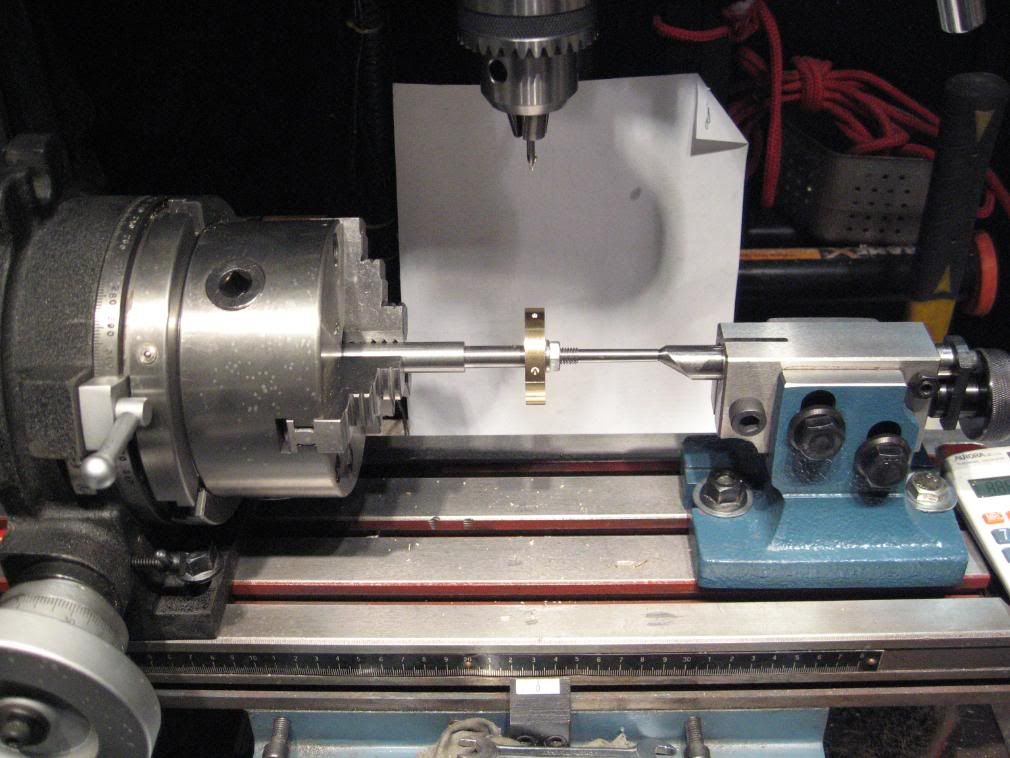

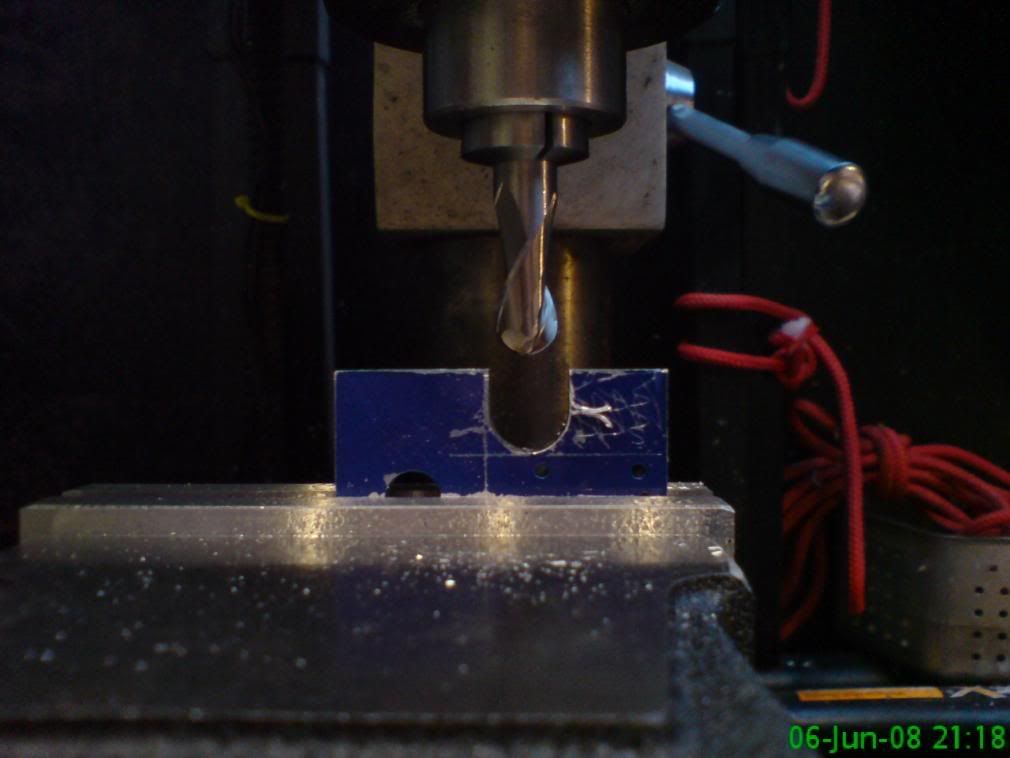

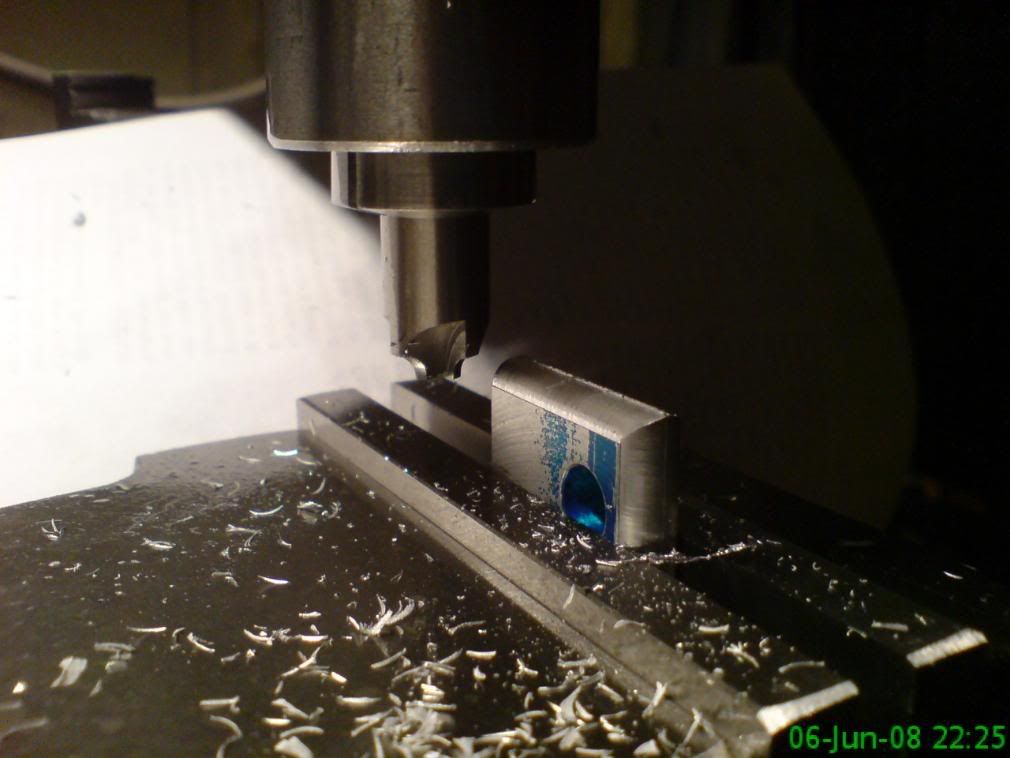

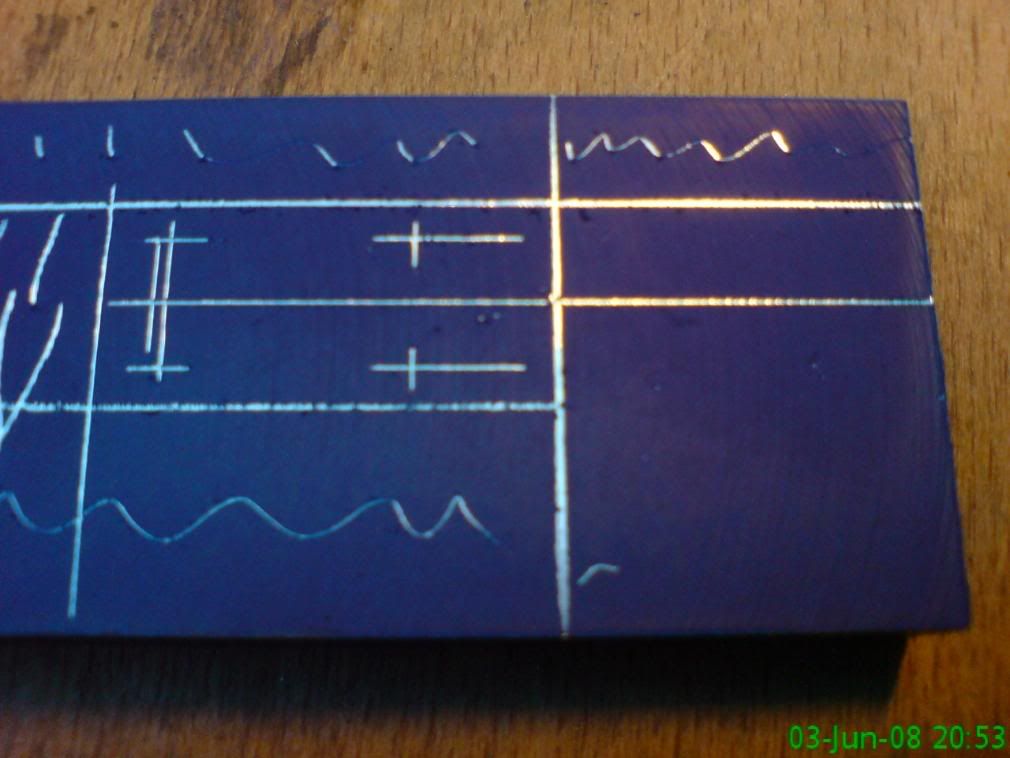

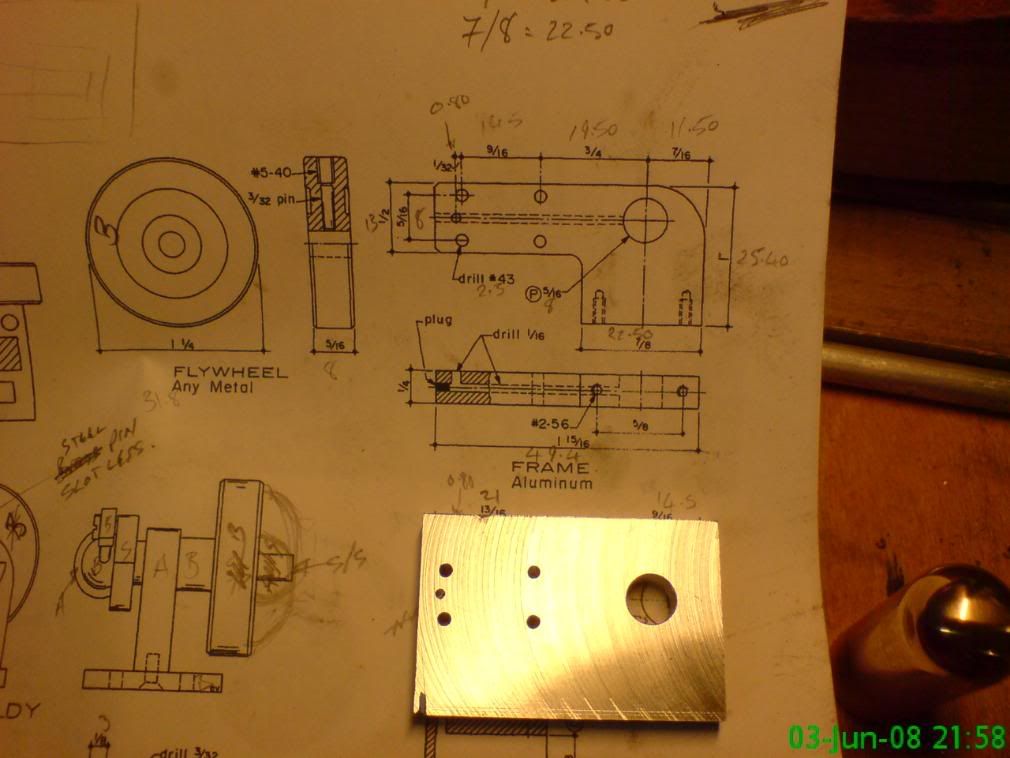

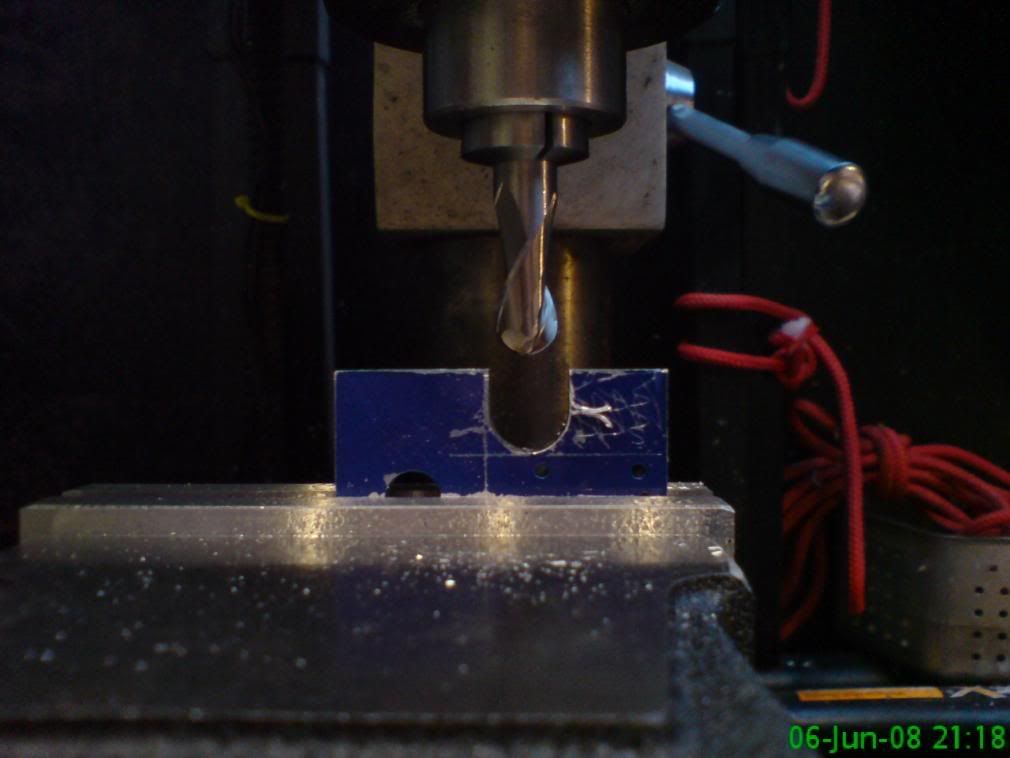

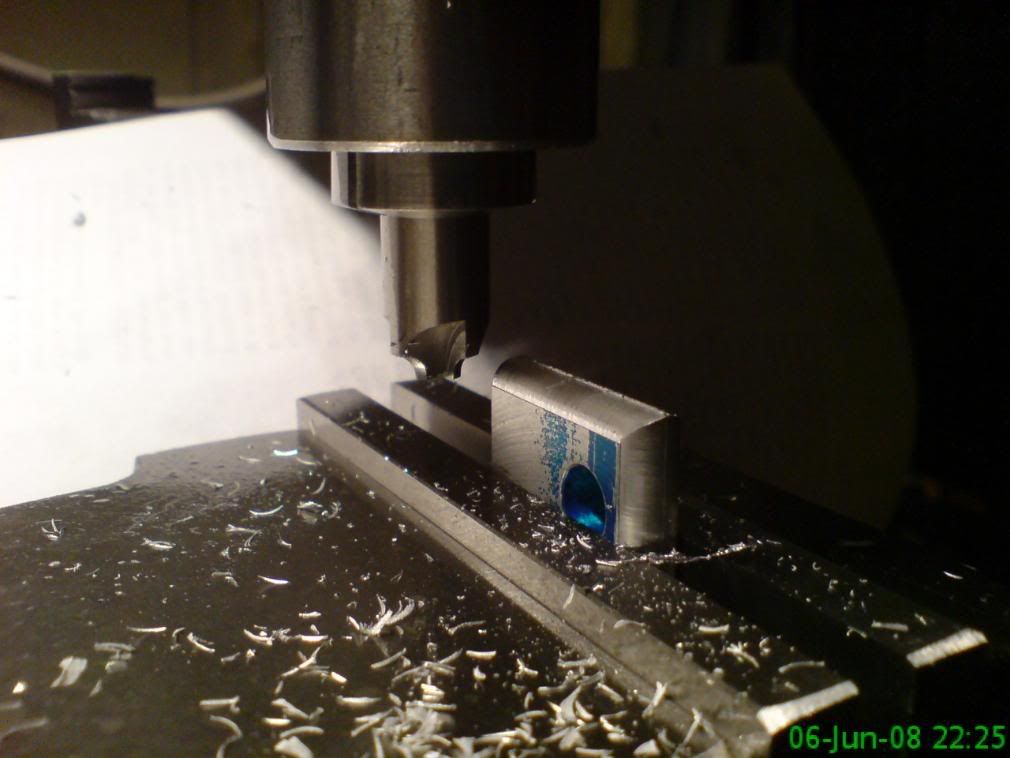

Here are a few photo's of my attempt to follow some plans to make a steam engine (even though it'll run on air for a little while first ;D )

Obviously I can't stick to the plan exactly... Something in me just says 'style it!!' so I am styling it a little... but the heart of the plan is staying intact

That's pretty much it for now... I haven't been in the shop for 6 days!!!!!!!!!!!! I can't believe it, I've just been too busy and too tired to know I'd work safely. (you can see from the pic' dates... Too busy to even post this any sooner!)

I can't believe it, I've just been too busy and too tired to know I'd work safely. (you can see from the pic' dates... Too busy to even post this any sooner!)

But tonight I'm back in there and going to enjoy every minute of it ;D

Here are a few photo's of my attempt to follow some plans to make a steam engine (even though it'll run on air for a little while first ;D )

Obviously I can't stick to the plan exactly... Something in me just says 'style it!!' so I am styling it a little... but the heart of the plan is staying intact

That's pretty much it for now... I haven't been in the shop for 6 days!!!!!!!!!!!!

But tonight I'm back in there and going to enjoy every minute of it ;D