I have lots of pictures, lots of measurements, and lots of doubts. This is a very enticing project but I have not fully committed to it yet. Having the bones of this old engine so close at hand makes it all but impossible to ignore but the obstacles are many.

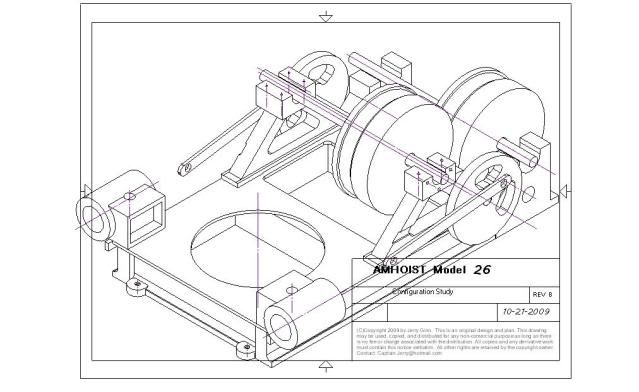

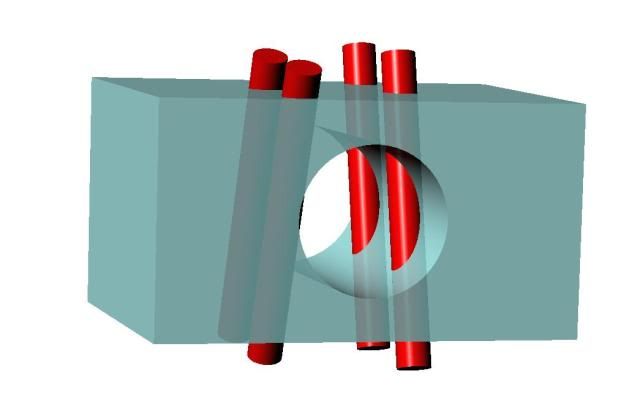

1. Plans. I would like to produce a model of THIS engine and while I have seen some plans offered, they are not this exact engine as far as I can tell. Close but not quite. This engine is one of the smaller models produced by American Hoist. Bore of 6.25", Stroke of 10" makes it a model 26 "EAGLE". There was a smaller one with 5.5" x 8" bore and stroke, the Model 24 "HABIT". These two models were unique in that the clutch and brake are on the same side of the drum. Larger models had the brakes on the opposite end of the drum for improved cooling. All plans and actual models of steam donkeys show the brakes and clutches separate.

2. Scale. If I make this model large enough to faithfully reproduce all detail would require a bigger shop and a bigger lathe. If I make it too small, some details will be compromised.

3. Complexity. I have never cut a gear. I have never cut a square thread. I have never cut a double start thread. Left hand double start square thread screw and nut, HA!

4. Live Steam. Maybe as a second phase.

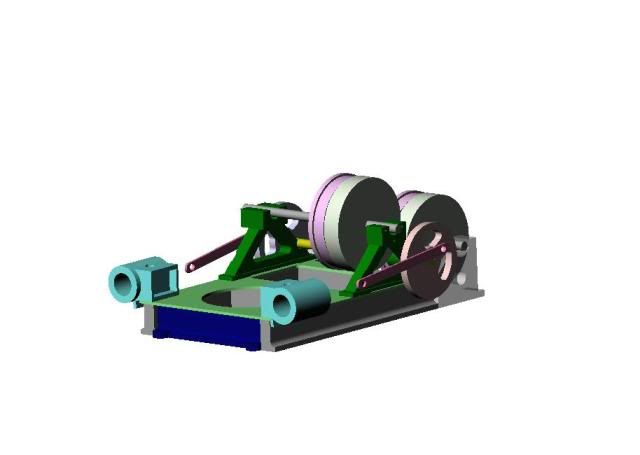

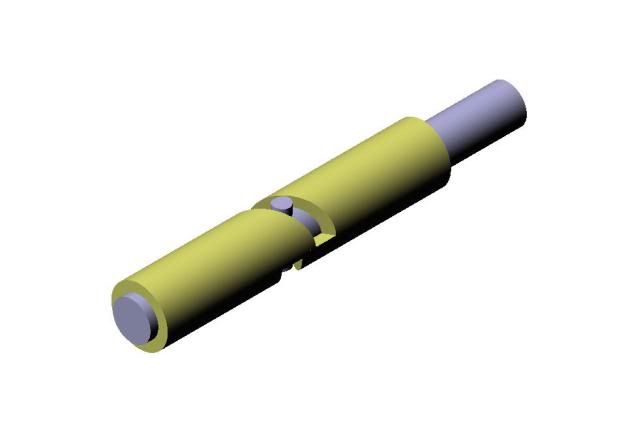

I think I'm beginning to get serious about this. Here is the results of some Alibre modeling I did last night. This is pretty accurate as to actual dimensions. I'm thinking of using a 1/10th scale. I haven't cut any metal yet, but I'm getting close. Suggestions are welcome

Jerry