Jared:

Thanks for your reply. A picture of your dad's truck and would be interesting, but I enjoy neat old equipment. In my younger days, I was in the mining and earth moving equipment business and I have sold my fair share of Caterpillar, Komatsu, American Hoist (draglines), Mack (off-road mining trucks, LeTorneau, and Euclid equipment and have toured all of their factories (and museums). I've driven a chain drive Mack and I've pulled the levers on an electric Marion dragline. I won't say I "operated" the Marion, just pulled the levers through a few cycles under the VERY watchfull eyes of the real operator. That may explain the natural interest in building this steam donkey.

I'm curious why you're selling your sailboat. A man without a boat is a man in chains, as the old Norwegians used to say.

Posted on: April 17, 2010, 01:06:05 AM

I'm selling the boat because it has served it's purpose, which I only recently decided what it's purpose was. It eased my transition into retirement and gave me focus and confidence that I was not "over the hill". Sailing has been a big part of my life for the last ten years. It has kept me healthy and interested in life. I will miss it but I can do other things now.

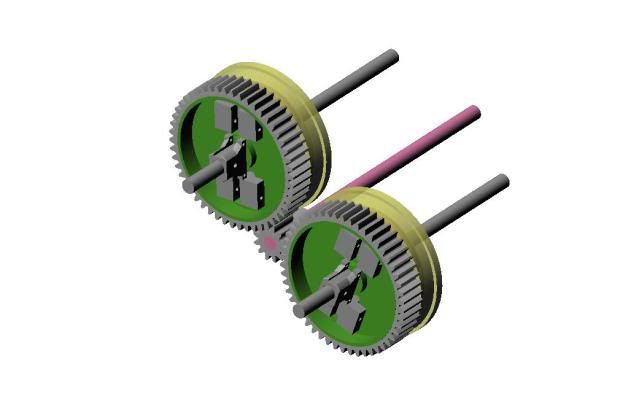

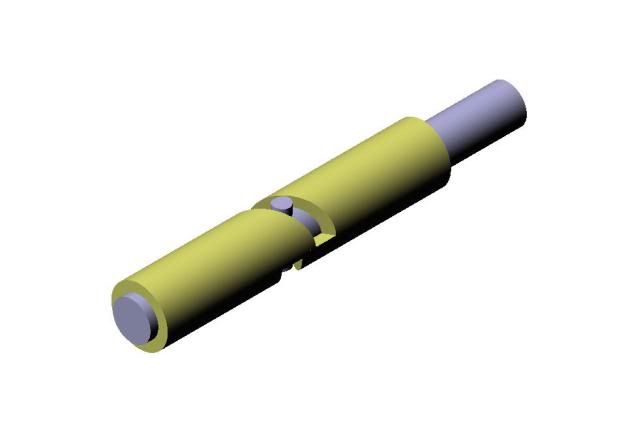

I never touched a metal lathe until I was 70 and now I do things that I never did. I think I have a good handle on 3D CAD with lots more to learn. I may make a set of gears soon. My son-in-law asked me if I wanted to attend a welding course with him and I will. My wife starts talking very fast and tries to distract my attention when we drive by the Harley dealership and If I start to miss the boat too much, I have a big teak deck box which isn't going with the boat, so I can take it out in the hot sun and varnish it. That will let me miss th boat less.

Jerry