Hi

Iv just ordered an SX4 and have a question if anyone has one or the SX3

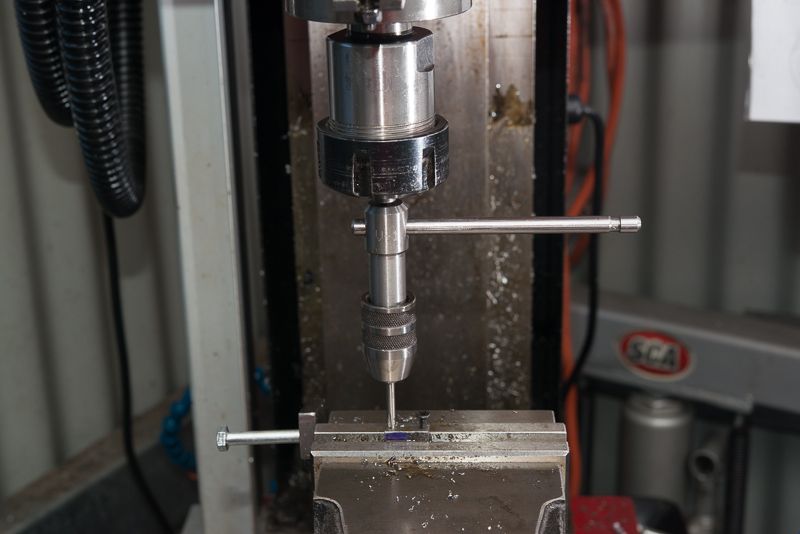

Its regarding tapping, can you tap blind holes with it , im wondering how you stop it from bottoming out as im sure you wont be able to reverse it before it hits the bottom of the hole .

Rob.

Iv just ordered an SX4 and have a question if anyone has one or the SX3

Its regarding tapping, can you tap blind holes with it , im wondering how you stop it from bottoming out as im sure you wont be able to reverse it before it hits the bottom of the hole .

Rob.