You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show your neat stuff

- Thread starter mgbrv8

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lakc

Well-Known Member

steamer said:Pattern makers shrink rule!

Dave

Yes, but arent they specific for the material?

mgbrv8 said:I have never even heard of that, can we elaborate on the Pattern makers shrink rule? ???

Dave

Metal shrinks as it cools, so when casting, you need a larger form or pattern then you want the end result to be.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

IIRC pattern makers rules are set up increments of eighths per foot. 1/8, 1/4, 3/8... then one uses the appropriate one for the metal being cast.

tin

tin

Lakc

Well-Known Member

I dont want to drift too far into off-topicville, since this isnt a shop tool per se but it is prettry neet stuff.

This is a General Radio 1650 Impedance bridge. Mid 1960's vintage labratory grade equipment, it is notable here for its mechanical underpinnings.

Its mostly made of precision wire wound resistors. The big drum on the bottom has a swash plate style cam with a roller follower. The follower pivots the contact back and forth along the resistor wire allowing the fine tuning of the resistance value across its entire travel.

More of a "neet mechanisim" then tool (to most here). ;D

This is a General Radio 1650 Impedance bridge. Mid 1960's vintage labratory grade equipment, it is notable here for its mechanical underpinnings.

Its mostly made of precision wire wound resistors. The big drum on the bottom has a swash plate style cam with a roller follower. The follower pivots the contact back and forth along the resistor wire allowing the fine tuning of the resistance value across its entire travel.

More of a "neet mechanisim" then tool (to most here). ;D

Mosey

Well-Known Member

Very neat!!

Me thinks it belongs to the golden age when ships were wood, men were iron, and radios had tubes.

Bring it back.

Hallicrafters and WB Dumont

Me thinks it belongs to the golden age when ships were wood, men were iron, and radios had tubes.

Bring it back.

Hallicrafters and WB Dumont

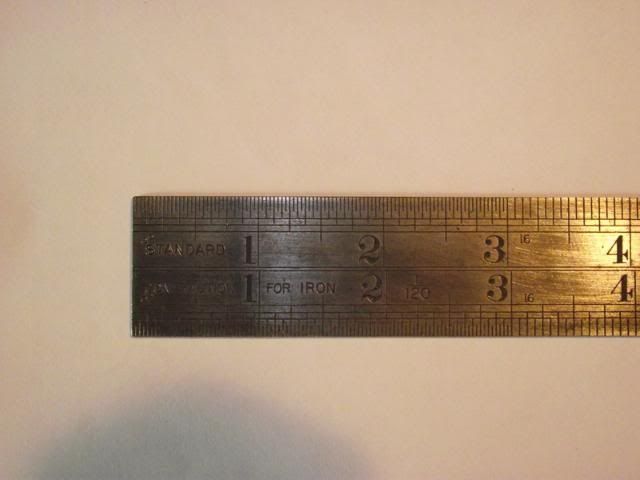

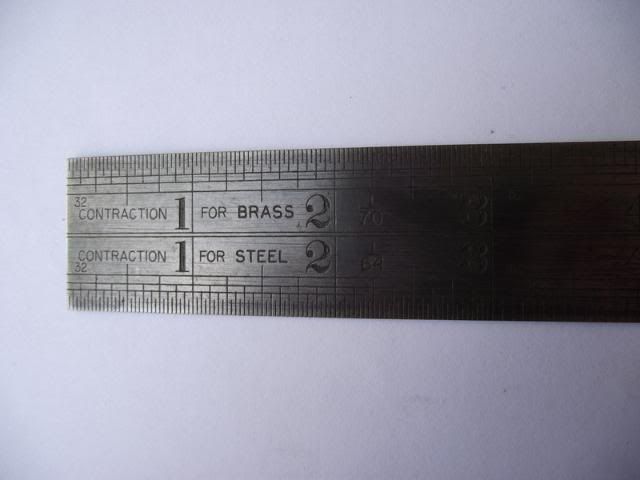

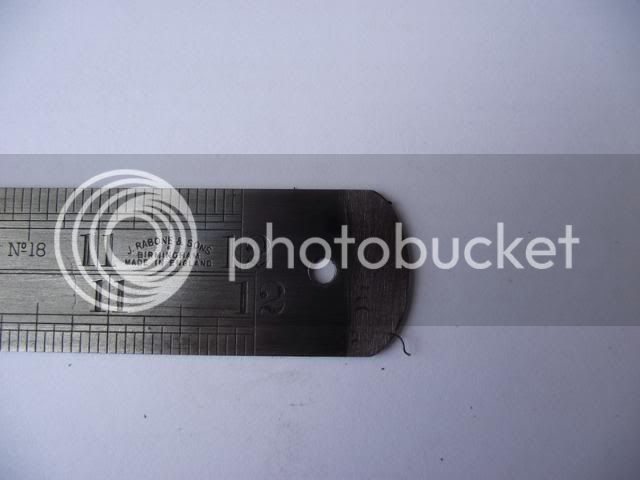

Maryak said:I was given this 12" scale recently.

At 1st my reaction was................... th_wtf1

But all is not lost............hint...........I'm pretty sure George Britnell knows what it is. ;D

Best Regards

Bob

OK for extra points....This is a shrink rule for which metal? ;D

Dave

steamer said:OK for extra points....This is a shrink rule for which metal? ;D

Looks to me to be 1/8 to the foot (figuring by it being 'off' 1/16 at the 6" mark), which would make it good for cast iron.

All of my shrink rules (Starrett 370 series, Lufkin 83 series)have the same 'shrinkage' on all the ruled areas and don't have a non-shrink rule. Who made that one?

steamer said:ding ding ding ding ding ding rkepler gets the prize....who did make it?

I'd guess Union, but it's not much more than a guess. It's not Starrett or Lufkin, the numbers are bold like Union did and the only lettering I can see ends "on".

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Congratulations to Dave and RKepler.,

1st prize is a week at my workshop and 2nd prize is 2weeks. ;D

Actually it's for several metals, I don't know the manufacturer but will sort it all out next Friday and post some pics of the markings.

Best Regards

Bob

1st prize is a week at my workshop and 2nd prize is 2weeks. ;D

Actually it's for several metals, I don't know the manufacturer but will sort it all out next Friday and post some pics of the markings.

Best Regards

Bob

- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

This saw blade called an Abra file is a godsend to me and I would love to buy some more,but havent located any in the UK yet.it will cut in any direction but snaps very easily if you don't keep your mind on what you are doing.

Don

Don

I don't think I saw a patternmaker's rule that had different shrinks, sounds to me to be a good chance for error in picking it up and using the wrong scale. Nice find.

I was reminded elsewhere that I had this out in the shop:

Not something you see every day. It's a tool for characterizing the wear on a machine tool. It's bigger than you think - the cylinder in the back of the box is 8" long. I originally bought it for some work on a lathe but used other techniques, I do plan on using it when I rescrape my mill (someday).

I was reminded elsewhere that I had this out in the shop:

Not something you see every day. It's a tool for characterizing the wear on a machine tool. It's bigger than you think - the cylinder in the back of the box is 8" long. I originally bought it for some work on a lathe but used other techniques, I do plan on using it when I rescrape my mill (someday).

Lakc

Well-Known Member

Of all the scraping tutorials and other info I have accumulated over the years, that tool is the missing link to how you get both sides of a dovetail or way the same height. Thanks!

dsquire

Well-Known Member

- Joined

- Mar 18, 2008

- Messages

- 980

- Reaction score

- 15

don-tucker said:This saw blade called an Abra file is a godsend to me and I would love to buy some more,but havent located any in the UK yet.it will cut in any direction but snaps very easily if you don't keep your mind on what you are doing.

Don

Don

I would love to see a picture of the Abra file if you have one. Thanks.

Cheers

Don

Lakc said:Of all the scraping tutorials and other info I have accumulated over the years, that tool is the missing link to how you get both sides of a dovetail or way the same height. Thanks!

Actually, that measurement is not that hard to get - checking for level the long way then level across with 1-2-3 blocks and a long flat with a level on top (fitter's rule is best, it won't sag {much}). Parallel on the verticals is fairly easy with some pieces of linear bearing - on diameter and straight. But you can also do it by scraping in some keys for the dovetails and measuring across them. That's all from memory so don't take it as gospel, for that you'd want to check "Maching Tool Reconditioning".

What this guy does is help you jig up to get the initial measurements of just where the error is - a lot of the stuff in MTR that's rigged for the job is done here by setting the clamps, getting the levels set and walking the tool along the work. If you're used to the "old way" you may well find that easier.

Similar threads

- Replies

- 55

- Views

- 20K

- Replies

- 0

- Views

- 2K

- Replies

- 2

- Views

- 10K