- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

After breaking several 3/64" drill bits drilling pilot holes in my V8 connecting rods, I decided I needed a sensitive drilling fixture. Actually, it's probably more just the fun of building than actually having one, but, still, it would be a handy addition to the shop. So, while waiting on delivery of some 8-40 taps and dies for my V8 air engine, I decided to build me one.

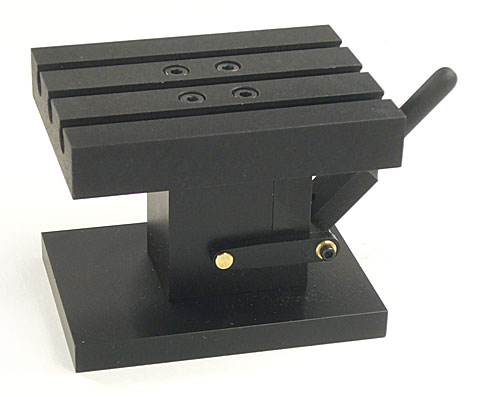

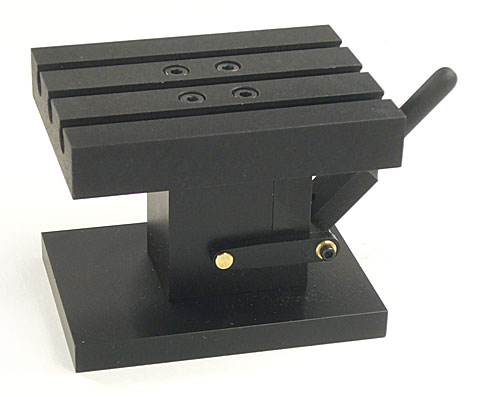

My design will be similar to the Hummingbird Drilling Table designed by Jose Rivera and marketed through The Little Machine Shop. However, it's currently out of stock and I don't know if it's been discontinued or not.

I favored this design over the drilling table featured in HSM because the HSM model has a rotating table and you can't secure work to it for drilling. It is, however an elegant and simple design.

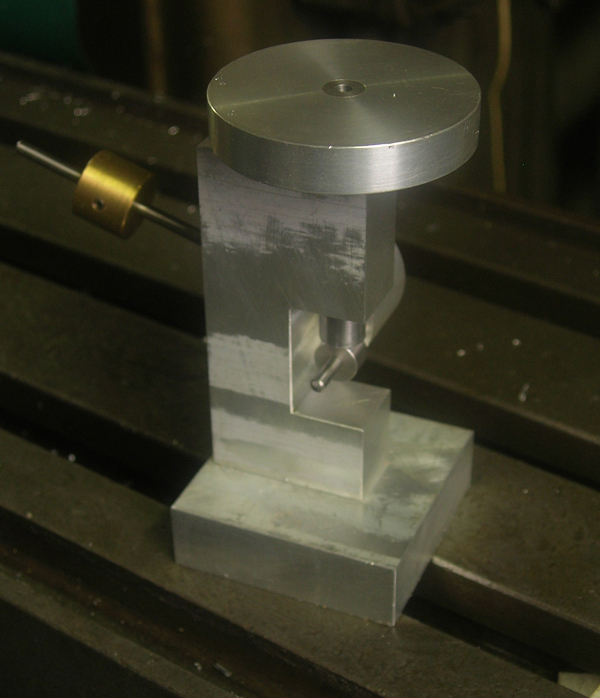

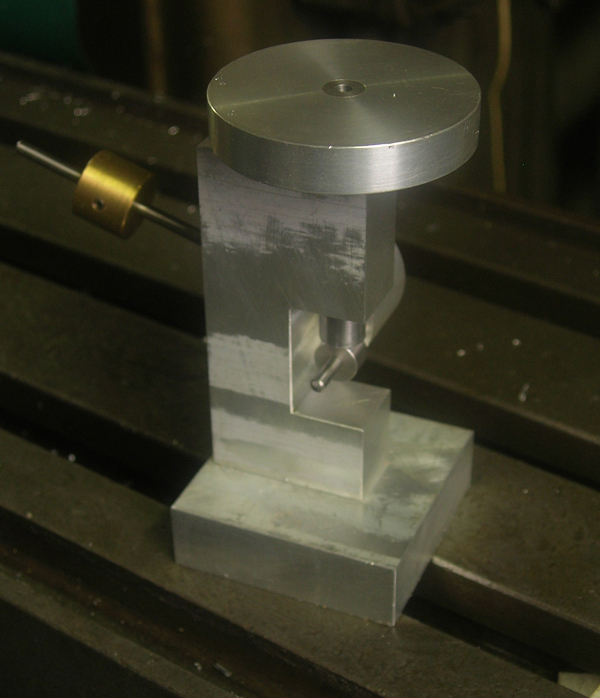

Simple enough to build my own. My design uses a small linear slide which has an aluminum body with steel ways and counter rotating angular rollers. I'm also using a 3/8" thick steel base for weight and stability. The rest of it will all be aluminum.

As an aside, I picked up a set of ball end hex drivers yesterday from Ace Hardware. Almost $25 with tax, but these little guys are really going to be a useful addition to my shop. Makes installing and removing socket head cap screws really fast and easy.

Chuck

My design will be similar to the Hummingbird Drilling Table designed by Jose Rivera and marketed through The Little Machine Shop. However, it's currently out of stock and I don't know if it's been discontinued or not.

I favored this design over the drilling table featured in HSM because the HSM model has a rotating table and you can't secure work to it for drilling. It is, however an elegant and simple design.

Simple enough to build my own. My design uses a small linear slide which has an aluminum body with steel ways and counter rotating angular rollers. I'm also using a 3/8" thick steel base for weight and stability. The rest of it will all be aluminum.

As an aside, I picked up a set of ball end hex drivers yesterday from Ace Hardware. Almost $25 with tax, but these little guys are really going to be a useful addition to my shop. Makes installing and removing socket head cap screws really fast and easy.

Chuck