- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

The Corliss project plans calls for a number of radiused edges, and a few beads. The edges I usually did with a file, belt sander, a bead is a bit tougher as it is a positive standout feature and will show much more if done poorly.

Having a yet as untried Radius and Angle Dresser for the surface grinder it was as good time as any to give it a go.

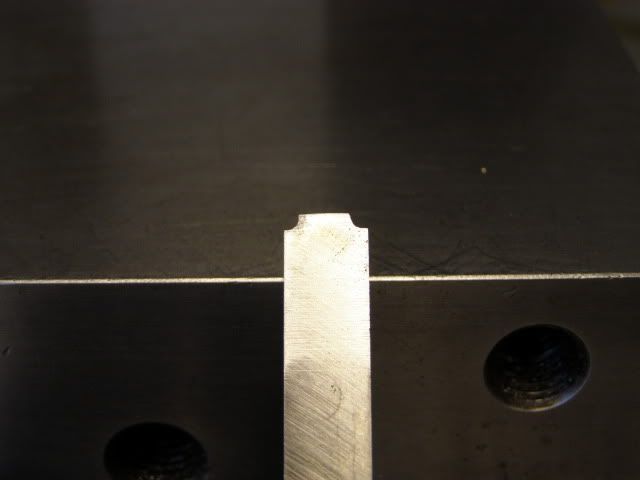

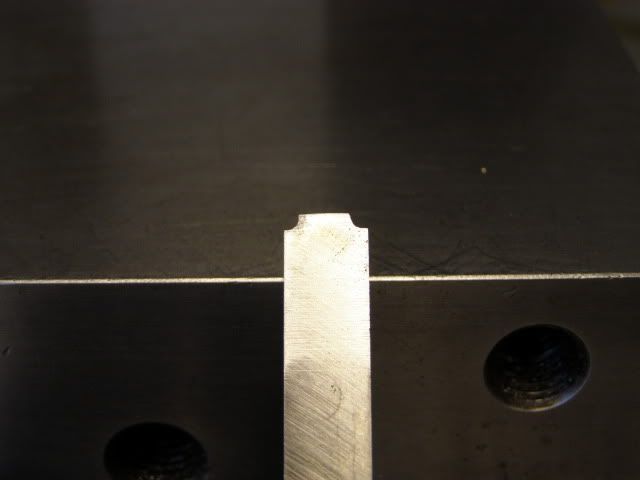

A wheel was dressed with a 1/16"R and ground a good looking groove in a piece of HSS bit. On the opposite end a right and left 1/16R were also ground in.

This is the L&R radius end

Results when used, The material is 12L14, L to Right, L Radius, plunge cut of 3/8 bit with 1/8" bead form, bead form on a .130 flange, another L Radius.

Most folks make their own form tools like this.

A question to you, would anyone be interested in purchasing a form tool such as this? is it worth $10, 15, 20. Let me hear thoughts on the subject. Thanks

Having a yet as untried Radius and Angle Dresser for the surface grinder it was as good time as any to give it a go.

A wheel was dressed with a 1/16"R and ground a good looking groove in a piece of HSS bit. On the opposite end a right and left 1/16R were also ground in.

This is the L&R radius end

Results when used, The material is 12L14, L to Right, L Radius, plunge cut of 3/8 bit with 1/8" bead form, bead form on a .130 flange, another L Radius.

Most folks make their own form tools like this.

A question to you, would anyone be interested in purchasing a form tool such as this? is it worth $10, 15, 20. Let me hear thoughts on the subject. Thanks