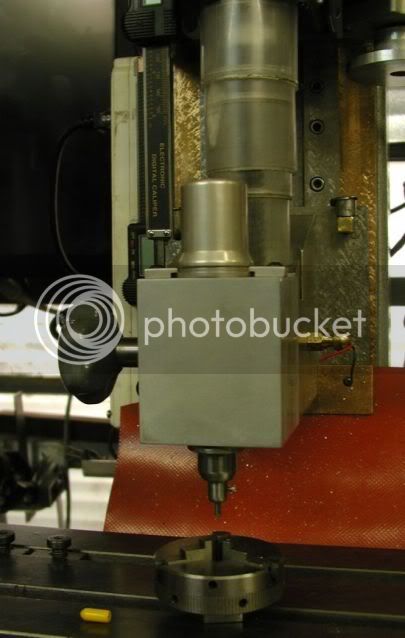

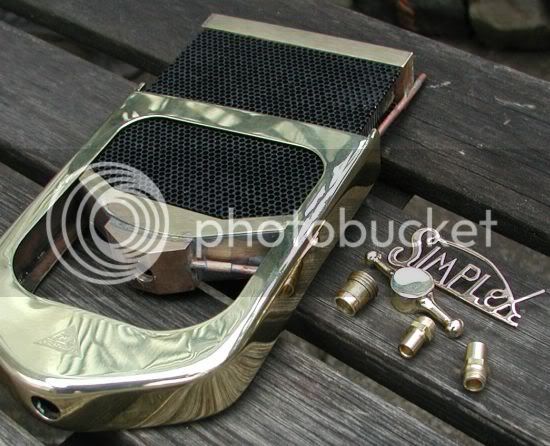

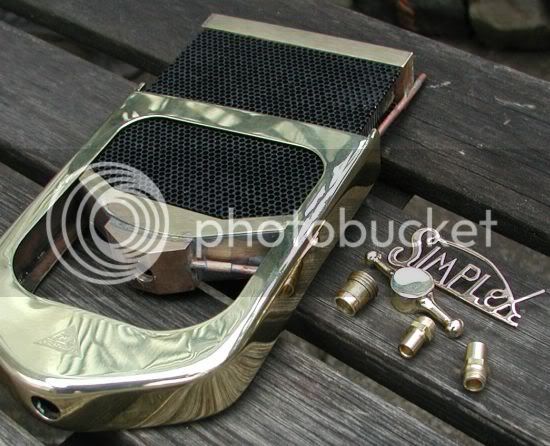

Some pics of just finished radiator. Started out what I think was section of a car heater core that was about 5/8" (16mm) thick. Top tank sides and bottom are silver brazed together and the bottom tank milled out of solid brass. Slots 1/16 wide milled for the 10 tubes to fit through. Electronic type rosin core solder and solid solder from a radiator show was used. Solid solder from radiator shop was much better at gap filling. For a honeycomb look the grills were made by drilling about 1,400 of 3/32 holes per side. Thanks to homemade mini cnc mill the hole spacing came out good. Also cnced was the Simplex logo cut out, tube slots and logo engraving.

The shell is made of 3 pieces silver brazed. Front, back and strip bent for sides and top. Inlet and outlet are thread 5/16-40. Radiator cap is 3 pieces silver brazed.

No plans were used and overflow tube wasn't planned ahead for. Had to route through the top tank to get it to come out the bottom. Looks like the radiator will work but it is not as good as might appear in the pictures.

Hose clamps made from brass strip

The shell is made of 3 pieces silver brazed. Front, back and strip bent for sides and top. Inlet and outlet are thread 5/16-40. Radiator cap is 3 pieces silver brazed.

No plans were used and overflow tube wasn't planned ahead for. Had to route through the top tank to get it to come out the bottom. Looks like the radiator will work but it is not as good as might appear in the pictures.

Hose clamps made from brass strip