- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

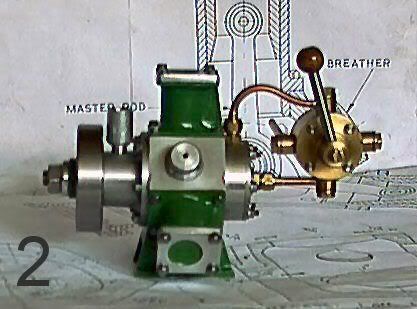

I liked the look of this engine and decided to make it my next project

I downloaded and printed the plans,my thanks to Stewart Hart

If anybody has made this engine i invite you to post on this thread

As usual i made a few changes but basically followed the plans

As i start this post the engine is approx 90% complete as i wanted to confirm

that i could do a reasonable job before advertising my limited skills

I wanted a slightly larger version so upscaled x 1.3.Then nudged the holes and screws etc to suit std items and tooling.I will post with photos but not in the order that the items were made.I made the cylinders,the photos show some setups.Also the conn. rods which were a little tricky.How i envy those with cnc

Lots of setups to make both the (casting) and machined faces and fitted brass bushes. Big end 8mm,small end 4.8 (3/16) to suit reamers.of which i dont own many.Long way round from the old fashion school of engineering.More work on jigs and fixtures than than on the parts.TBC

I downloaded and printed the plans,my thanks to Stewart Hart

If anybody has made this engine i invite you to post on this thread

As usual i made a few changes but basically followed the plans

As i start this post the engine is approx 90% complete as i wanted to confirm

that i could do a reasonable job before advertising my limited skills

I wanted a slightly larger version so upscaled x 1.3.Then nudged the holes and screws etc to suit std items and tooling.I will post with photos but not in the order that the items were made.I made the cylinders,the photos show some setups.Also the conn. rods which were a little tricky.How i envy those with cnc

Lots of setups to make both the (casting) and machined faces and fitted brass bushes. Big end 8mm,small end 4.8 (3/16) to suit reamers.of which i dont own many.Long way round from the old fashion school of engineering.More work on jigs and fixtures than than on the parts.TBC