- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

kcmillin said:that could be quite a high revving engine, if built right. No valve springs=no valve float. although the recipricating mass would be vary large.

Very interesting design. It reminds me a a design of an engine I heard about a while ago. Something like the pistons sleeve would move up and down opening and closing ports. Ime not really sure.

Kel

kcmillin said:that could be quite a high revving engine, if built right. No valve springs=no valve float. although the recipricating mass would be vary large.

Very interesting design. It reminds me a a design of an engine I heard about a while ago. Something like the pistons sleeve would move up and down opening and closing ports. Ime not really sure.

Kel

Royal Viking said:Hi Feliks,

Have you also considered the relation of the camshaft to the weight of the timing crankshaft?

kf2qd said:Some thoughts -

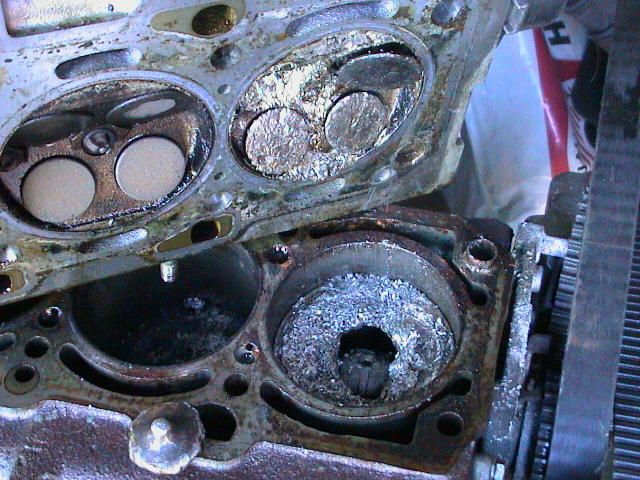

RIngs and pistons used as valves. Means you have to have small ports or bridges across your ports to keep the rings happy. Those are high wear areas and are also the weak points in the design. Those are just 2-cycle pistons used a little differently. It looks inexpensive, but where is the wear. What about the flow of gases into the cylinder - will this desigh limit how fast eh engine can breathe? And it also makes for a much taller head to accomodate the pistons and rods. If you want to get rid of valve springs then go desmodromic.

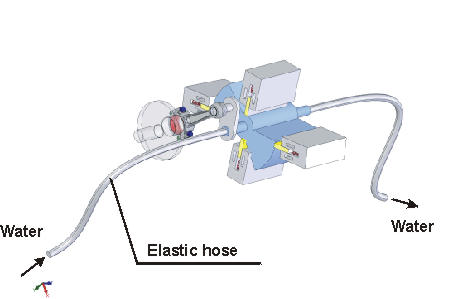

As for those oscilating generators - they can't get very big or the forces on reversing direction will be enormous. For best results you want the armatures to cross the magnetic fields at a high speed otherwise the output voltage/current will be low.

kf2qd said:As for those oscilating generators - they can't get very big or the forces on reversing direction will be enormous. For best results you want the armatures to cross the magnetic fields at a high speed otherwise the output voltage/current will be low.

kcmillin said:that could be quite a high revving engine, if built right. No valve springs=no valve float. although the recipricating mass would be vary large.

Very interesting design. It reminds me a a design of an engine I heard about a while ago. Something like the pistons sleeve would move up and down opening and closing ports. Ime not really sure.

Kel

Enter your email address to join: