chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

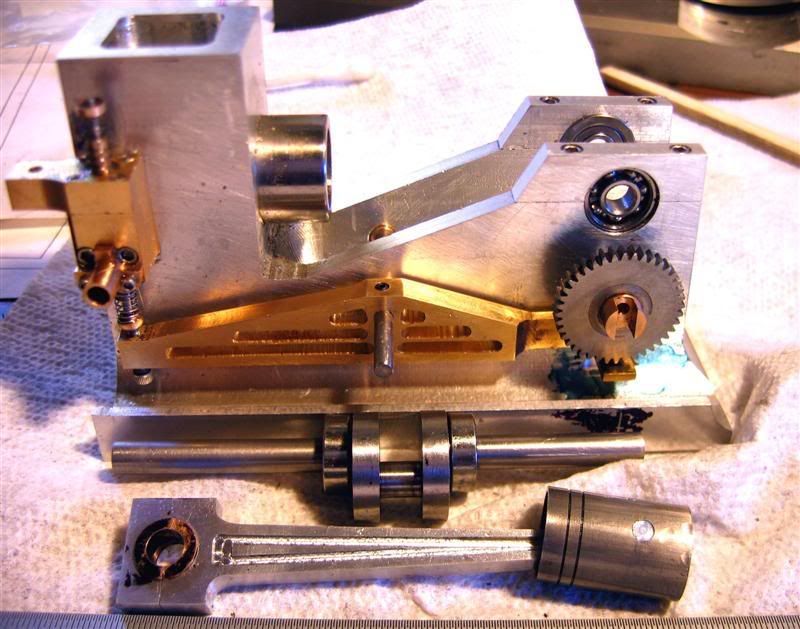

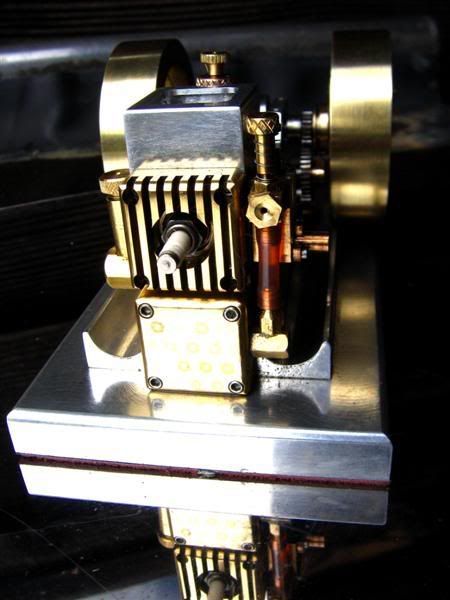

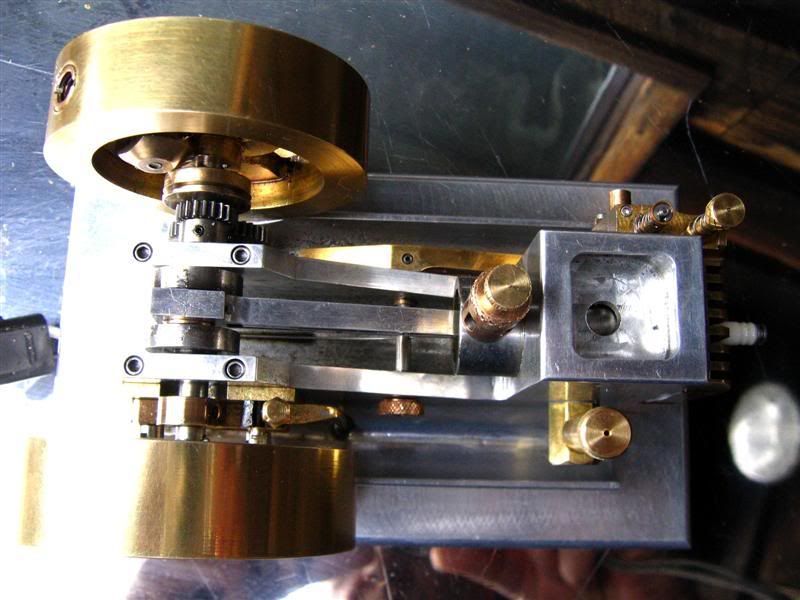

well i have been working on one of bob shores engines the last couple of days and i must say it has been a challenge for me. it is a model called the little angel. bob drew it up as a 1/2" bore 1/2" stroke engine. well i got inspired by a a guy i know by the name of bill huxhold to make it smaller (bill builds very small model steam engines).

so i thought i would just half all the dimensions. well that is easier said than done. since the smallest model i have built has a 7/8" bore and that is a far cry from a 1/4" bore. i have had think in a whole different way, like how to hold some of the smallest parts and how to drill and tap 00-90 holes!

i have included a couple of pics to give you an idea of what i have been up to.

the first pic shows the engine frame or base with a lighter for comparison.

the second pic shows the base with the gears and a #0 center drill for comparison

the last pic shows the intake valve beside a 0-80 x 1/2" long cap screw, the valve stem is 0.032 in diameter

i'm sure many of you fellas out there have done something this size and i would like ideas on how to tap 00-90 and smaller holes. i have never taped anything smaller than 0-80 and i just know i will need help,so if you have any suggestions tips tricks or tools to make this job easier i'm all eyes and ears.

thanks

chuck

so i thought i would just half all the dimensions. well that is easier said than done. since the smallest model i have built has a 7/8" bore and that is a far cry from a 1/4" bore. i have had think in a whole different way, like how to hold some of the smallest parts and how to drill and tap 00-90 holes!

i have included a couple of pics to give you an idea of what i have been up to.

the first pic shows the engine frame or base with a lighter for comparison.

the second pic shows the base with the gears and a #0 center drill for comparison

the last pic shows the intake valve beside a 0-80 x 1/2" long cap screw, the valve stem is 0.032 in diameter

i'm sure many of you fellas out there have done something this size and i would like ideas on how to tap 00-90 and smaller holes. i have never taped anything smaller than 0-80 and i just know i will need help,so if you have any suggestions tips tricks or tools to make this job easier i'm all eyes and ears.

thanks

chuck