Bill_Rittner

Active Member

- Joined

- Jun 11, 2015

- Messages

- 26

- Reaction score

- 11

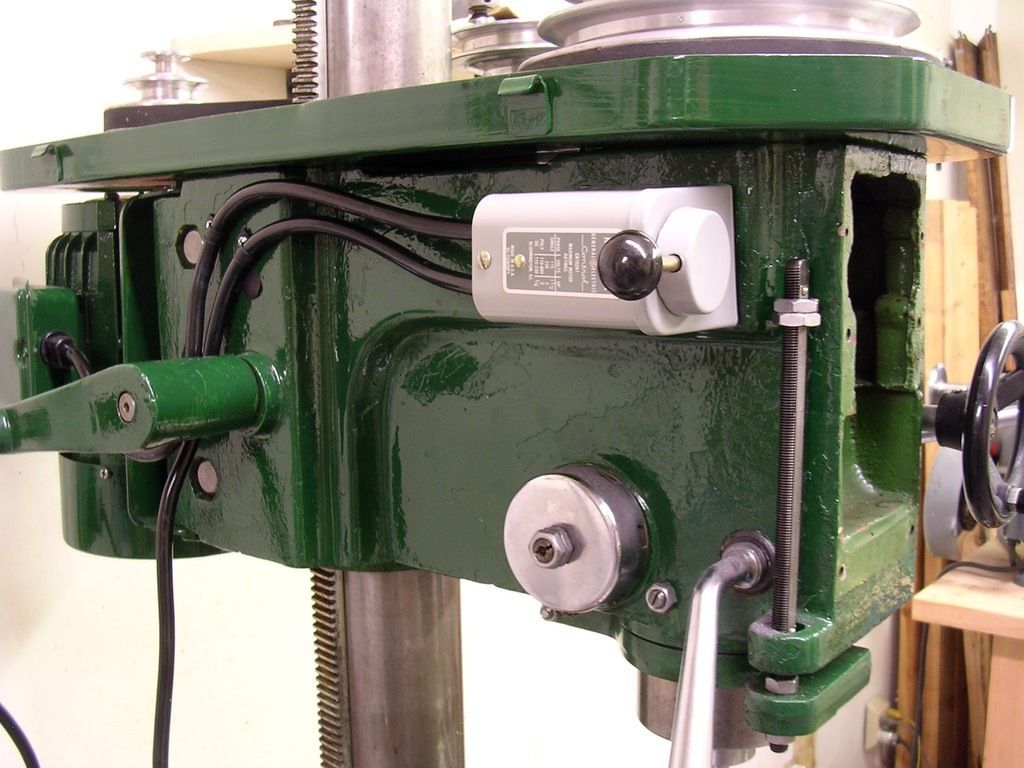

My years of milling machine experience have taught me that a mill spindle needs reverse, something the RF-30 does not have. I use reverse for power tapping and running left hand tools. Left hand drills are great for removing broken screws. They often grab and back the screw right out. So I decided to add a new spindle switch with a reverse function. I found an appropriate drum switch. The original switch was removed and the wires were pulled out. I put plugs in the wire holes. The original wire clamps were used on the back of the switch. Then I drilled and tapped 4 holes in the machine head and mounted the switch. The original wires were hooked up in the switch and held in position on the side of the machine with a couple of cable clamps held on with screws in two more tapped holes. I now have forward and reverse.

The next order of business was covering the front of the head where the original spindle switch was located. I made a cover out of 3/16" thick aluminum plate. Mounting holes were drilled in the corners and holes were drilled and tapped to re-mount the spindle speed chart. I drilled and tapped four holes in the head casting and mounted the cover and the speed plate.

This was an inexpensive and easy upgrade.

I am currently in the process of gathering parts and materials to put this mill on CNC control.