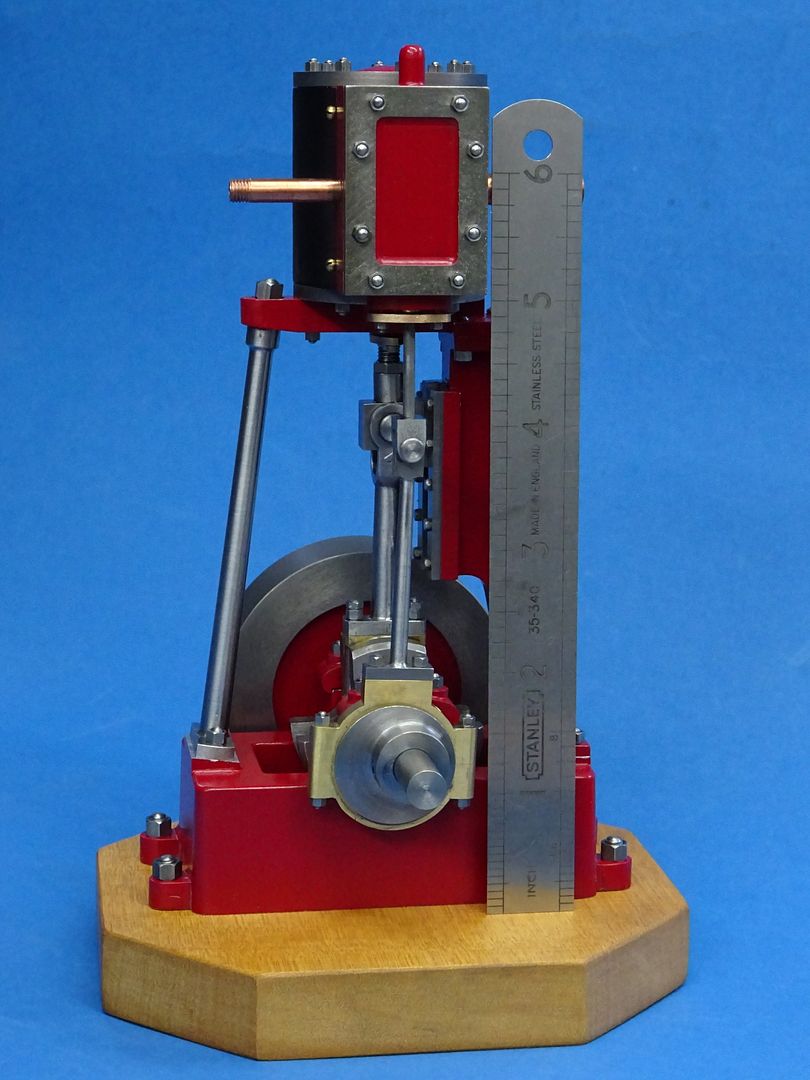

Hello again, Thanks for the Photo's. Stuart 5A both engines look real. i have a question or two, i cannot find Ray Hasbrooks descriptions of all the engines indicated in his book, unless i buy a copy, which i am going to do. My question is, in the book, is there a set of plans for a small double Vertical say with 1 to 1 1/4 bore, or a single with a single with a 1 1/4 bore that would fit my 7 ft. tugboat? could someone please answer this question thanks. i ordered a few sets of plans as beginner projects on my Lathe, the first a scale steam ships winch, the second, a hobbyist table saw, third a set of plans for a model outboard lower unit, designed for a 049 . the table saw is for a 4 to 5 inch blade, i need this to cut flat brass and other metals, all the componets for the saws drive system are contained in the drawings, made of metal rounds. the mini outboard lower unit i wish to perhaps produce say five of them, keep one sell the rest, the steam winch, again build five keep one, sell the rest, i might make five table saws, keep one sell the rest, i will use the profits for more tooling for my lathe and mill, i wish to someday buy a bigger lathe say one that is 8 by 20 or something like that!

Some information now on my.monitoring Drill Press Conversions to milling machines an interesting subject for those interested. ok i know some will Mock the very suggestion, but i have watched a few( what i refered to as a poor mans milling machine) the question i had was, can it actually be done? well yes and no is the answer, one fellow tried a year ago or so and failed completely, but the reason is that he did not have a Lathe to build the modification parts required. Vertical drilling with a Drill Press is fairly accurate, but any sideways loads and the drillpress Quil goes out of alignment, i have watched several people try with only two success stories reported recently. one of these, the fellew that successfully modified one, made some changes to his drill press, he indicated that a standard drill press quil bearing cannot take side loads and has alot of run-out when attempted, so he removed the quil and removed the bearing he then enlarged the hole the bearing sits in and he installed a wider bearing, the problem was that the clearence between the bearing and quil was not close enough in tollerence he ended up with a run out of 000.5 according to his dial indicator once the modification was completed. he also installed a threaded bolt to lock the unit and also added a worm gear with dial wheel, he seemed quite pleased with the results that is all i know for now. i will not comment on these conversions, accept to say that a milling machine is very expensive, and the cost for one has never come down here on ebay the cheapest is 1000.00$ .

i was looking a stuarts websight at the No7 yes two of these would be wonderfull, but unless i win the lottery, i will stick with the Ray Hasbrook option, the 7's are 245.00$ pounds Stirling which is about 400.00'$ Canadian plus taxes, duty and postal costs for each units castings. now finally some bad news, i found out that the manufacture of my lathe did NOT bolt the motor in place, its sitting in its small cavity loosely,i have decided that i am going to tear the lathe apart and rebuild or clean the entire thing up, i could send it back but thats more trouble then its worth, and as small as it is 7×14 its so heavy i can hardly lift it, mine has a 100 mm. three jaw chuck and 100mm centre height, its a nice lathe. i do not like the two plastic wheels one of which is on the tail stock , i also do not like the metal bracket holding the tailstock on the bed with a rediculious nut and bolt alignment method,also mine came with no wrench at all to remove the Chuck the instructions with the unit were simply garbage consisting of very little information and the parts schemetic required a magnifine glass to even read it, but when i finally went out and bought a magnifine glass i found out that the motor in the unit was not the motor indicated in the drawings of the parts schemetic that is on page 8 of the manual. mind you i only paid 500.00$ for the lathe apparently a new one. I could have bought the real mini lathe from china that has a 60 watt motor centre distance of 100 mm. but that will not build u a model engine. the lathes bed is very accurate, mine has all the features of the bigger lathes and a 550 watt motor of which does appear to be very heavy built, it has a small toothed belt their are some very plastic gears and spares that came with it, i think i will eventually convert it to metal gears and also a independant four jaw chuck is coming as well.

i still have Not received my tooling package i ordered from the little machine shop, but hopefully next week or the week after.

Regarding the mini outboard plans, These plans as far as i know are the only ones in existance, and this unit has solid bevel gears in the lower gear case, i guess i could make bevel gears for it via what is known as gear hobbing. or buy them they are in-exspensive. I am saddened that single cylinder diesel engines are no longer manufactured. i have noted a few modelers attenpts to build real diesel engine minatures, interesting? well must go, one other question i have is it true that a three jaw chuck is not as accurate as a four jaw. Thanks again for the two photo's some photos of Ray Hasbrooks engines would accepted as well.

Dan.