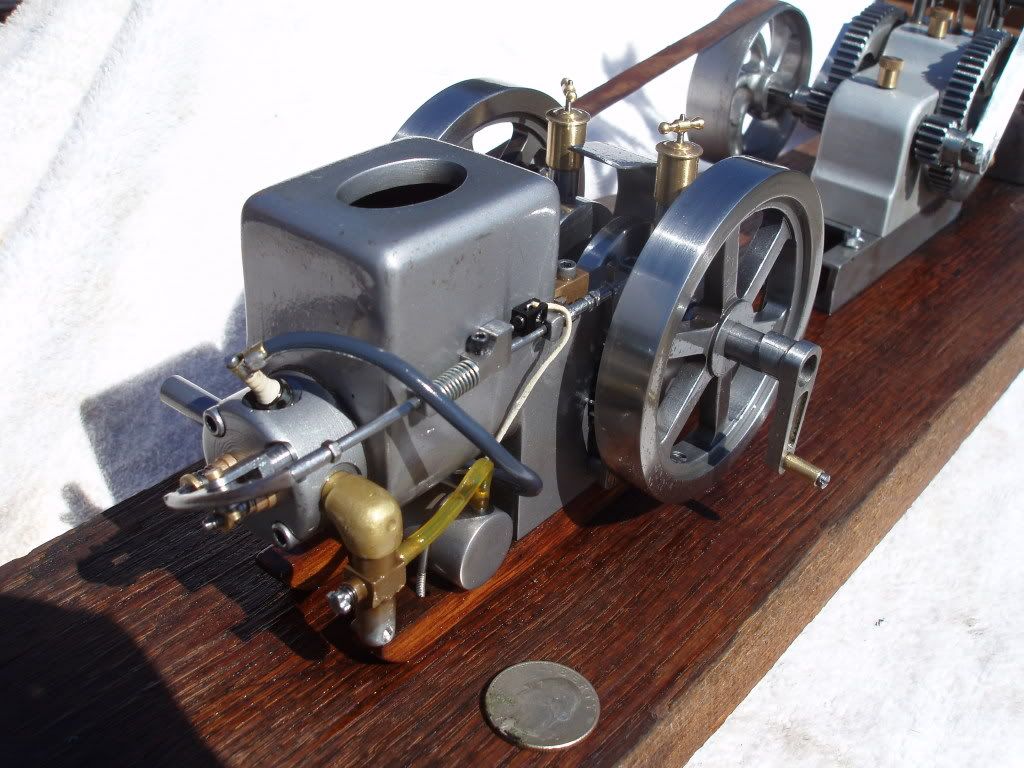

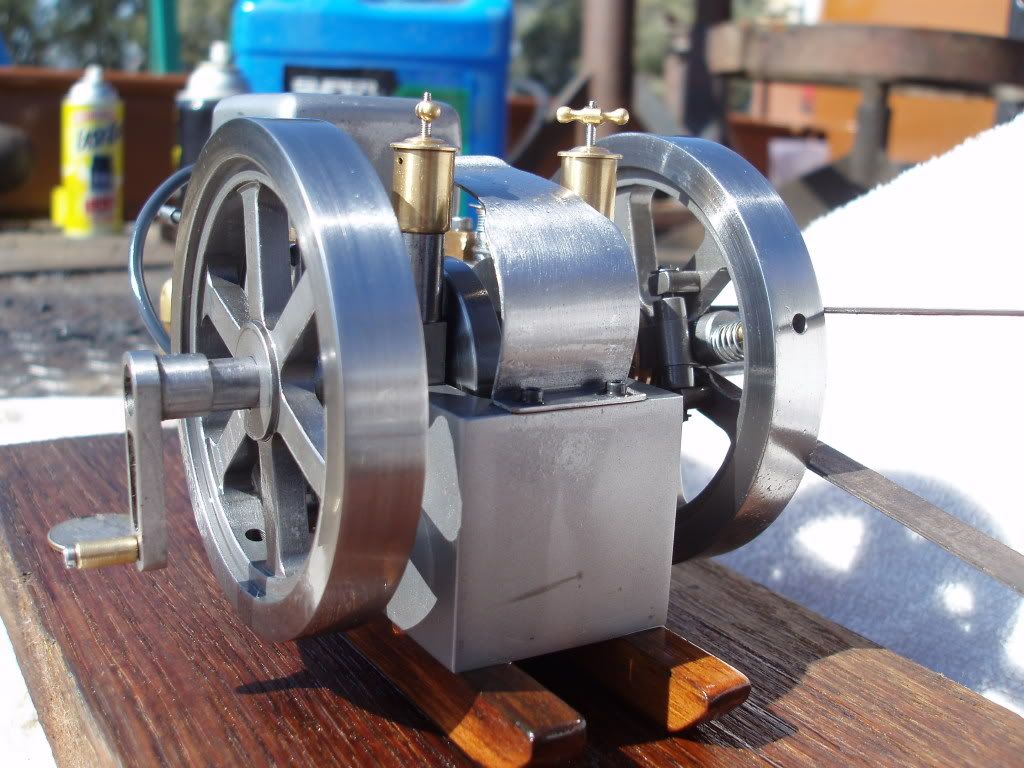

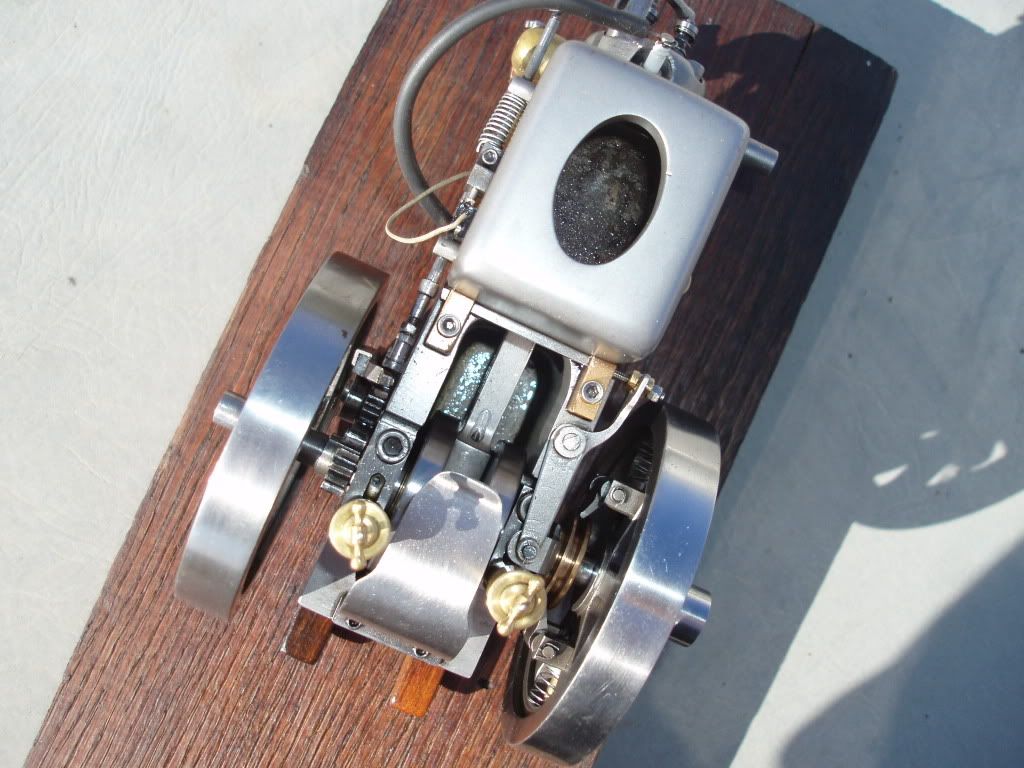

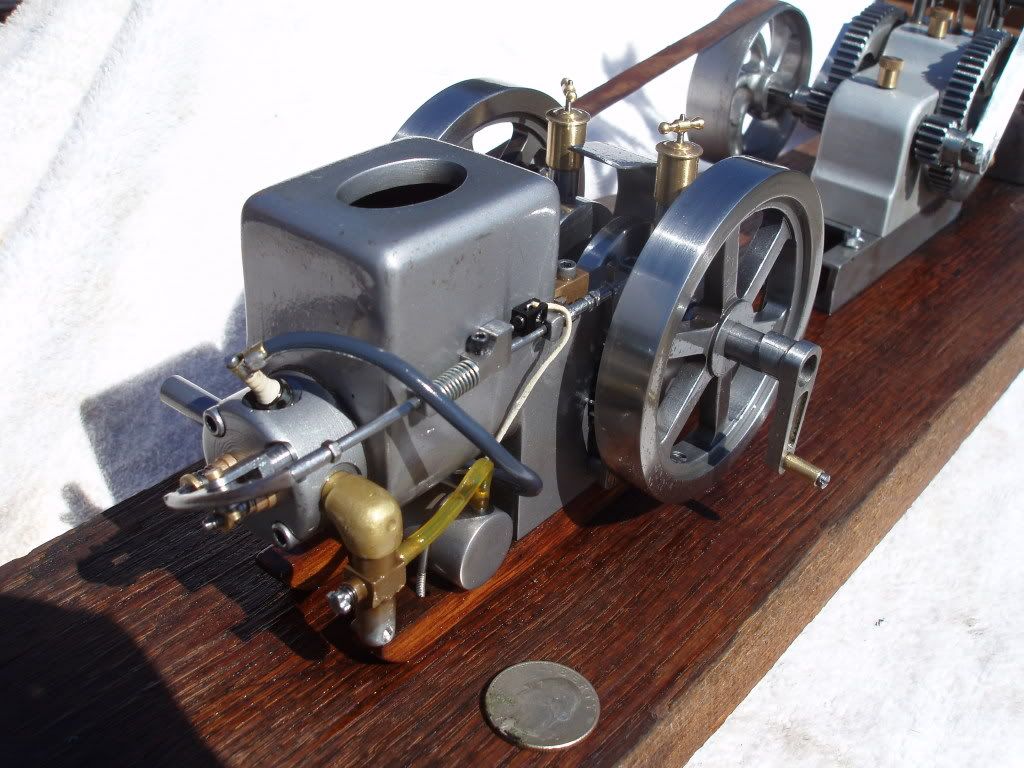

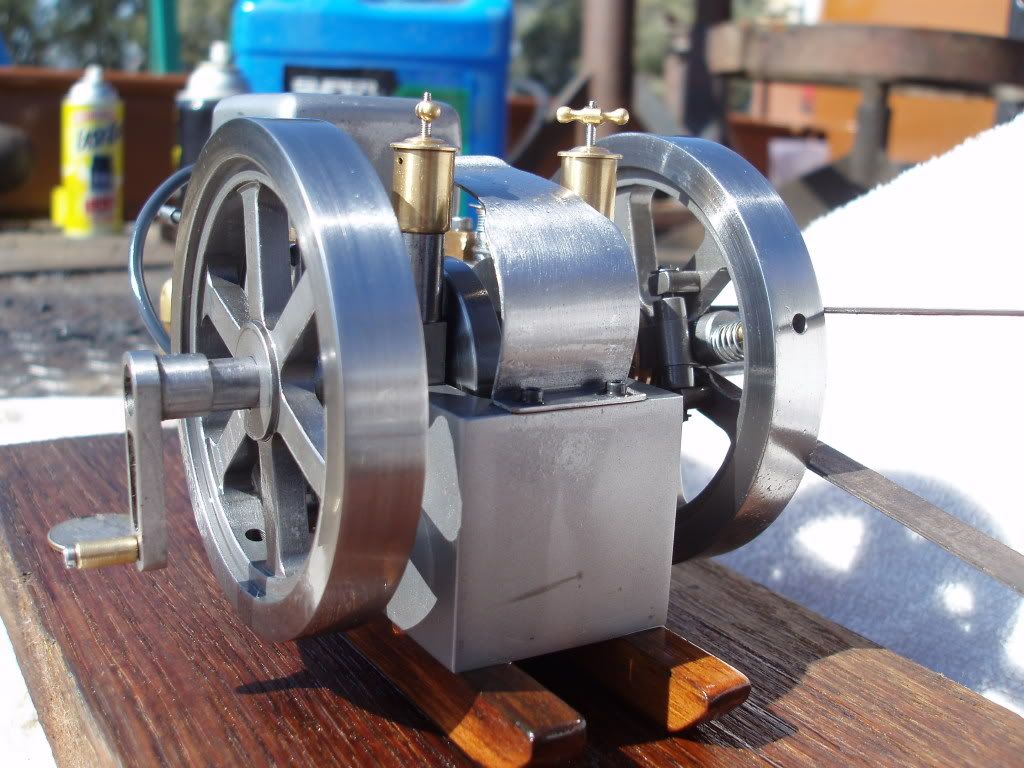

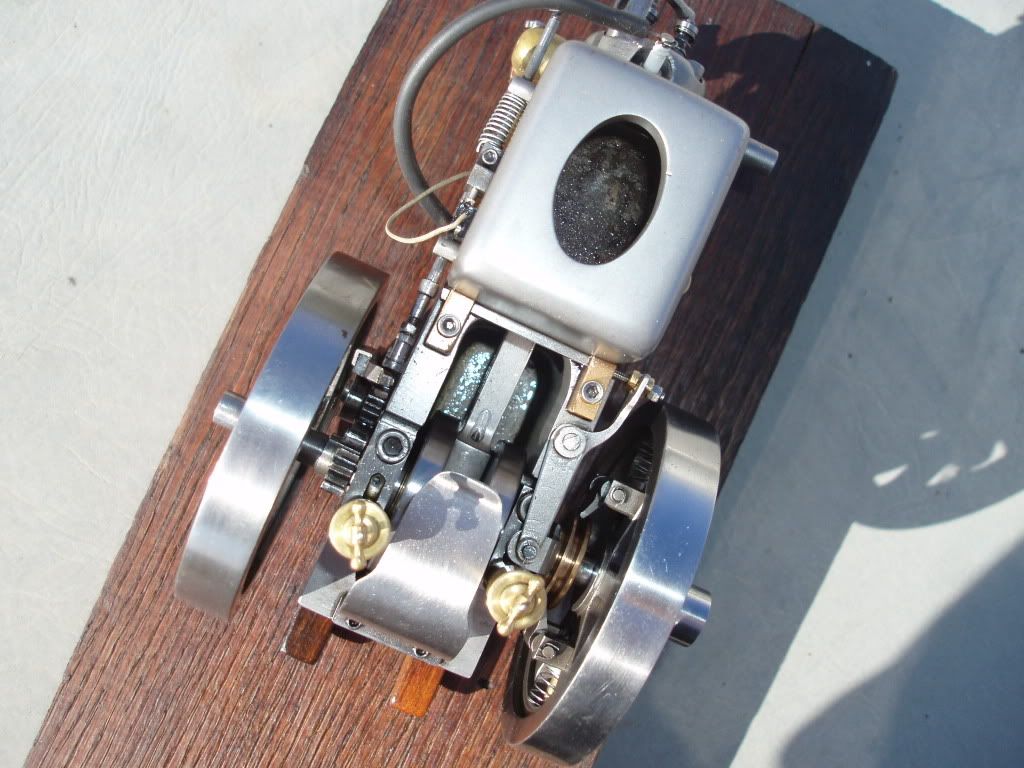

Hi guys, I sure do appreciate the compliments. I guess I can start out by saying that I had almost no milling experience or tooling before I started on this engine so there was a lot of redoing done. I was given an old, old, old Bridgeport that had been dropped and broke the head, I brazed it all back, trued it, added DRO when Sargon had a sale, but no ballscrews and I have a 13x38 Supermax lathe. The block started out as a chunk of 1018 steel and I kinda whittled it into shape, my expertise is welding, primarily TIG welding, so I roughed the water tank, Tig welded it into place then finish machined it, the sleeve is made from a small block Chevy wrist pin, cast iron piston, ductile rings from scratch, aluminum rod, ball bearing mains, stainless valves, cast iron guides (a later addition), valve springs from guitar strings, I learned to cut gears for the timing gears and the pump jack, I made my first spark plugs from porcelain, it uses a C&H CDI with tungsten points, ( I tried an ignition from a fellow in Florida but it just would not work with points where the C&H works very well) that is the delrin block on the side of the engine with the white wire. It is just grounded through the pushrod. I tried Hall effects but they kept burning up, they would last less than a minute and I got tired of soldering them so I went to points instead which is probably the Achilles heel of the whole engine with all the oil about and very low voltage. I use 3 in1 oil for lube and it runs on pump gas. The holes in the flywheels, the flywheels started out as solid, so they were drilled for set screws and then I decided to cut spokes, that exposed the holes in the rim, the holes in the governor side are for the brass shafts that the weights slide on, they have a screw slot below the surface and thread into the hub. When I cut the spokes it made the flywheels to light so I cut them smaller and shrunk on a rim for weight, they could be a bit heavier yet, this thing makes gads of compression and it could be slowed down more yet with more rotating mass, it runs at about 900 rpms and hits about 15 revolutions, any slower though you couldn't see the pump pumping. The pump has a 2 inch stroke x .250 diameter bronze piston with teflon leathers and integral check valve, stainless polish rod, brass stuffing box with graphite string packing.The pump jack is lubricated by knurled grease cups made from .250 brass rod. The curved spokes on the pulley were cut on a rotary table and then eased by hand. The building wasn't really the big hurdle, making it run right was, it almost went in the trash on many occasions, I just had to walk away but I was finally successful. I have displayed and ran it Cabin Fever Visalia CA. 2005, WEME 2008? and Pioneer Day festivities old engine show here in Paso Robles Ca, several times. Thanks ever so much for the interest, I will be glad to answer any questions that I can. Tad