A litle small for some of the commercial units about, but if it is your first foray into steam powered boats (I did it for many years) then a small twin oscillator of about 1/4" or 5/16" bore should be more than ample.

If you go too conplicated with your first efforts, and I have seen some right efforts in my time, you just might spend more time on the bank fiddling with it rather than sailing.

So just keep the C of G low, so maybe a horizontal boiler to begin with, and as I said, one of the smaller engines, that should give you good sailing with no surprises.

A sure case for KISS.

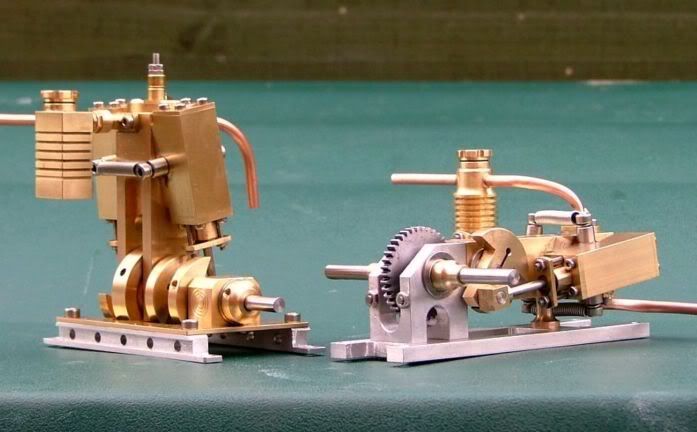

I have found that if making one yourself, with a little bit of good machining, the one at the bottom left on here could be made half size and would be perfect for your sized model.

http://jpduval.free.fr/Plans_moteurs_vapeur_p1.htm

Go to this page and you can go searching the site and there are all sorts of free and paid for plans available for download and have a look at.

http://jpduval.free.fr/

This is my version of the engine I mentioned above, made slightly easier to produce, and next to the blue engine which is the one in the picture below.

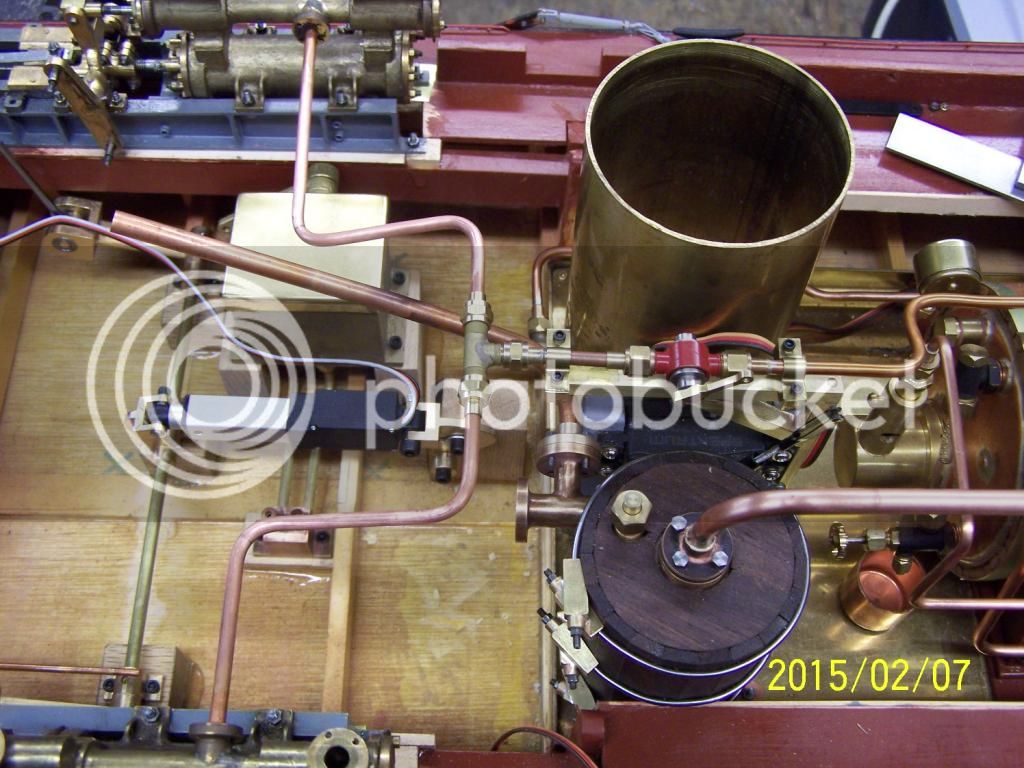

This is one of my steam boats from way back, sailed for ten years almost every weekend without a glitch. 4Ft long and powered by a commercial unit, which I still have in my collection.

I hope this helps a little

John