lazylathe

Well-Known Member

- Joined

- Aug 27, 2009

- Messages

- 1,285

- Reaction score

- 6

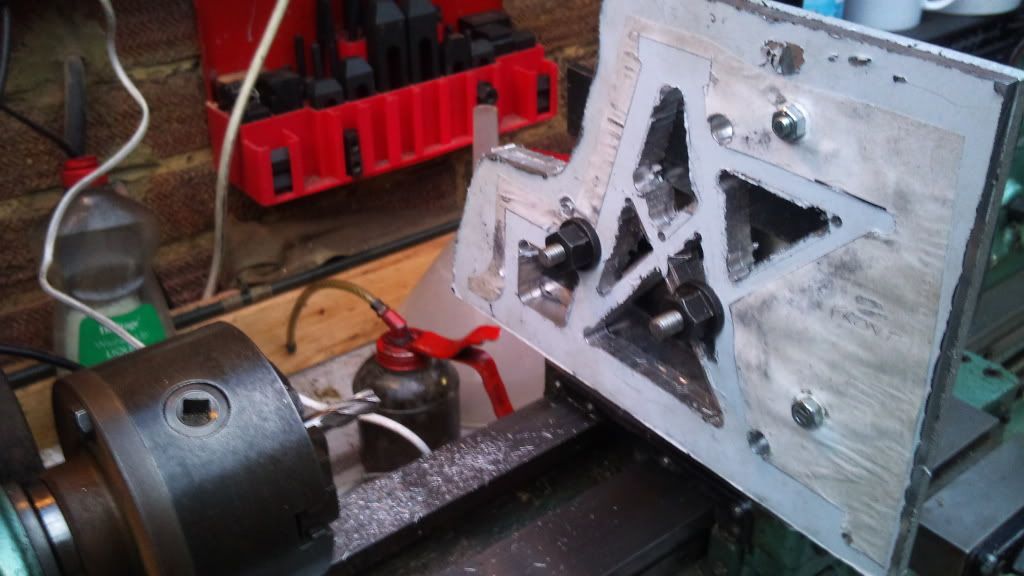

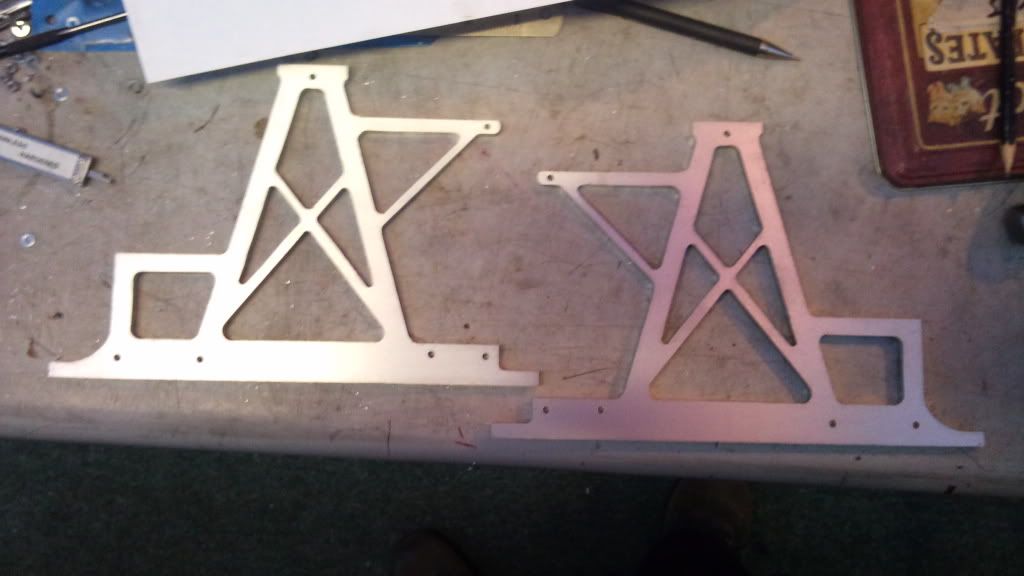

Okay, so i have the Myford metal lathe now and it is getting set up and adjusted.

I have bought a few new tools for it because some that came with the lathe are really old and not accurate anymore. A new 3 jaw chuck, QCTP, a new pulley for the 1/2hp motor and a few other bits.

I have been reading posts on milling on the lathe and a lot do not recommend it.

Flexing of parts and accuracy being of concern.

Is there an engine out there that one can build without the use of a mill??

Not having another $1000 plus to throw at a milling machine what options do i have?

I know i can still find the vertical milling tables for the Myford and a vise.

Use the collet set to hold the cutters etc...

Seen some people convert drill presses to "milling machines" and that scares me! ???

They are only designed for vertical forces and not lateral ones.

I suppose another way of asking the question is if i want to build a simple engine do i need a milling machine?

I tried when i had the Sherline lathe and it was extremely difficult to do...

Then looking at the prices of all the attachments i would need it kind of adds up very quickly and if i saved a bit longer i could most likely buy a small mill.

Also been looking at small shapers which appear to be quite neat but slightly limited in what they can do when compared to a mill.

Any help, ideas or suggestions would be greatly appreciated.

Andrew

I have bought a few new tools for it because some that came with the lathe are really old and not accurate anymore. A new 3 jaw chuck, QCTP, a new pulley for the 1/2hp motor and a few other bits.

I have been reading posts on milling on the lathe and a lot do not recommend it.

Flexing of parts and accuracy being of concern.

Is there an engine out there that one can build without the use of a mill??

Not having another $1000 plus to throw at a milling machine what options do i have?

I know i can still find the vertical milling tables for the Myford and a vise.

Use the collet set to hold the cutters etc...

Seen some people convert drill presses to "milling machines" and that scares me! ???

They are only designed for vertical forces and not lateral ones.

I suppose another way of asking the question is if i want to build a simple engine do i need a milling machine?

I tried when i had the Sherline lathe and it was extremely difficult to do...

Then looking at the prices of all the attachments i would need it kind of adds up very quickly and if i saved a bit longer i could most likely buy a small mill.

Also been looking at small shapers which appear to be quite neat but slightly limited in what they can do when compared to a mill.

Any help, ideas or suggestions would be greatly appreciated.

Andrew